Features of spring door closers

Spring door closer is a reliable device and is widely used in the installation of entrance and interior door groups. The product has high performance characteristics and is capable of operating without breakdowns for a long time.

Features and purpose

One of the main conditions for the correct operation of door systems is the smooth running of the door leaf and the absence of shock loading on the hinges and door frame. Installing a spring closer will help to solve the problem of soft and silent door movement. The device allows you to independently choose the closing speed of the door leaf and significantly reduces the wear rate of door fittings. As a result, the door system retains a presentable appearance throughout its entire service life.

Installation of a closer guarantees a significant reduction in the level of extraneous noise and significantly reduces heat loss in the premises in winter. Due to the tight fit of the canvas, it will be possible to get rid of drafts, which, in turn, leads to a reduction in heating costs and budget savings. The operation of the spring device is completely safe and quiet, which makes it possible to install the device in premises for any purpose, including residential and public spaces.

Products are highly resistant to aggressive environmental conditions, therefore, can be used not only for interior doors, but also be installed on entrance groups. The body of the devices is made of heat-resistant alloys, which makes it possible to operate the device in the range from -45 to +70 degrees.

However, not all products are highly resistant to extreme temperatures, therefore, when purchasing a device, you should carefully read the accompanying documentation. But almost all models have an anti-corrosion coating and can be used in high humidity conditions.

Design and principle of operation

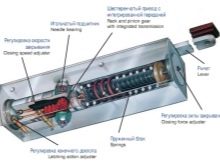

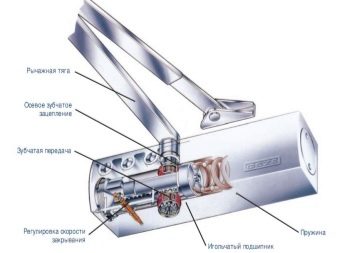

Structurally, a spring closer with a sliding rod is presented in the form of a body equipped with a working mechanism and connected to a lever-type rod. The working mechanism is made in the form of a rigid spring, the compression of which is carried out due to the action of the piston. The spring is placed in a sealed housing filled with oil, and after compression begins to gradually expand. Oil enters the housing through a network of hydraulic channels and provides a translational return of the spring mechanism to its original position.

Changing the closing speed of the curtain is carried out using adjusting screws installed at the end of the body. When they are turned, the size of the hydraulic channels changes, which leads to a slowdown or, conversely, an increase in the oil flow rate. It is the intensity of the oil flow into the cylinder that determines the speed with which the door will close.

If necessary, you can tighten or loosen the screw, as a result of which the door speed will immediately change.

Devices designed for installation on entrance groups are equipped with special valves that hold the doorway from an angle of 70 degrees until the door is completely closed. From about 15 degrees to close, there is a push-down pull. This is necessary in order for the canvas to easily overcome the air resistance and the door latch with a seal. In addition to the size of the section, the speed of the door is influenced by the viscosity of the oil in the working cylinder.This indicator is determined by factors such as external temperature, oil grade and duration of its use.

For example, at high temperatures and low oil quality, its fluidity increases and the resistance it creates decreases. With a decrease in temperature, as with long-term use of oil, its viscosity increases significantly and leads to an increase in resistance. As a result, the door starts to move more slowly and requires adjustment of the closer. This feature of spring closers obliges to timely adjust the door speed at least twice a year.

Varieties

One of the fundamental features of the classification of spring models is the installation location of the device. In total, according to this criterion, three types of devices are distinguished.

- Closer for outdoor installation. Models are designed for top installation and are considered representatives of the most budgetary group of devices. The device consists of two blocks connected by articulated levers, one of which is mounted on the door and the other on the box. All outdoor models are coated with an anti-corrosion compound and are highly resistant to extreme temperatures.

- Device for concealed installation in a door frame. Models assume the presence of a special cavity in the frame, designed to accommodate the device body. In this case, the lever is installed on the upper part of the door. There are also reverse models, when the working unit is installed at the end of the door leaf, and the lever is attached to the jamb. However, due to the complexity of installation, such devices are not widely used.

- Models for concealed installation in the floor. Closers are designed for heavy blades and can be used in warehouses and industrial plants. In addition, the design of hidden door closers allows them to be installed on swing doors, which significantly expands the scope and allows them to be used in public premises and shopping centers.

Criterias of choice

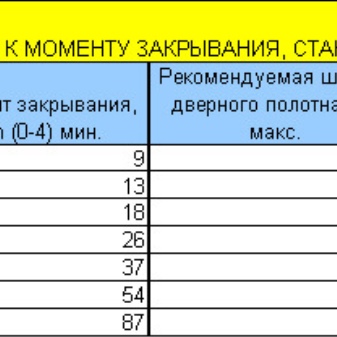

One of the important parameters by which a closer is selected is its power. When calculating it, first of all, they are guided by the dimensions and weight of the door leaf. The next selection criteria are the external conditions and the intensity of the flow of people through the doors. The power of spring closers is regulated by the European standard EN-1154, according to which there is a dependence of the class on power: the higher the class of the device, the more power it has.

For example, for large armored doors, it is necessary to choose models of the highest class EN-7, while for interior and entrance apartment paintings, a product of 3-5 class is quite suitable.

However, with the additional influence of external factors, the class should be chosen with a margin. Such negative factors can be a strong crosswind that blows most of the year, and high traffic.

In addition, a slightly higher class closer should be purchased even in the presence of non-standard canvases. For example, with a weight corresponding to the third class, but with a door height of 2.5 meters, you should buy a fourth or even fifth class closer. This will provide the necessary margin of safety and extend the life of the device. However, if there are no relevant indications for this, it is also not worth purchasing a higher class of closers. This is due to the fact that powerful models installed on a light plastic door or wicket will create a strong load on the fittings and cause their quick wear and tear.

The correct choice, setting and timely adjustment of the spring closer will significantly extend the service life of the device and make its use simple and convenient.

In the next video you will find an overview of the Hercules spring closer from the Luighi Aldeghi brand.

The comment was sent successfully.