Features of cork oak and rules for its use

Man has long learned to use the gifts of nature for his own good. Environmentally friendly, reliable materials are used in many areas of human activity. One of the amazing gifts of nature is the cork oak.

The material extracted from it is considered truly unique.

Description

The cork oak is one of the species of the genus oak, belongs to the beech family. An evergreen tree can grow up to 20 m.At mature age, it has a large trunk girth, which reaches a diameter of 1 m. A characteristic feature is the formation of a thick cork layer at the bark of the trunk and branches. On young shoots, the cortical layer is absent, they are covered with a thick felt yellowish-gray pubescence. The spreading tree has a powerful root system.

The leaf grows from a petiole, which can be up to 1.5 cm in length. The leaves are oval in shape, up to 7 cm long and 3.5 cm wide. The leaves are called whole-edged, they may have a small number of sharp teeth. Since the tree is evergreen, its leaves are leathery. Their upper side is shiny, dark green, the lower side has gray pubescence, in rare cases it can be almost naked.

Flowering is usually observed in May. Already in the first year, fruits ripen on the plant: acorns. The peduncle is short: up to 2 cm, 1-3 acorns appear on it. The fruits are oval, 3 cm long and 1.5 cm in diameter. The acorn is in a small cup (5 mm).

Cork oak is a thermophilic plant, frosts below -20 degrees are fatal for it. The tree is protected from many unfavorable environmental factors by a thick layer of specific cork bark, thanks to which it got its name. The cork has a dense cellular structure. It is formed by small cells interconnected. This structure can be compared to a honeycomb. The intercellular space is filled with gaseous substances.

An interesting fact is that the tree is valued precisely for its bark.

Its wood is not considered a valuable material, as it is very heavy, quickly rotting, cracking, warping. The material is more often used as fuel; charcoal is obtained from it. The bast is suitable for the extraction of tannins.

Where does it grow?

The natural natural zone for cork oak is a place with a warm climate, its homeland is considered to be Southwest Europe and North Africa. Therefore, it is widespread in countries such as Algeria, Tunisia, Portugal, Spain, which are the main producers of cork. And also the tree grows in France, Morocco, in some other countries.

The undisputed world leader in the production of cork is Portugal. It has a third of all cork oak forests in the world. The main producers of the material are the southern regions of the country. It is here that climatic conditions, ideal for an amazing tree, have developed with moderately rainy autumn, mild winters, hot and dry summers. In addition, in the southern lands of Portugal at an altitude of 500 m above sea level, the mineral composition of the soil is suitable.

Under natural conditions in Russia, cork oak does not grow. The first seedlings appeared in the country in the mid-1920s. The largest plantings were made in the Caucasus near the cities of Sukhumi and Gagra, in the Crimea in the famous Nikitsky Botanical Garden.

In order to establish its own production of high-quality material and not to import an expensive product, in the pre-war years, the Soviet government planned to create large plantations of a valuable tree in 30 years. The plans were not destined to come true. The avenues of oak in the Caucasus and Crimea have no industrial value. They are treated more like a decorative type.

However, in Russia, in the Far East (Khabarovsk Territory, Amur Region, Primorye), Amur velvet, or Amur cork tree, grows. It is not a relative of the cork oak, but it also develops a thick layer of cork.

This material is less valuable than its counterpart from warm countries, but it is also widely used in various industries and construction.

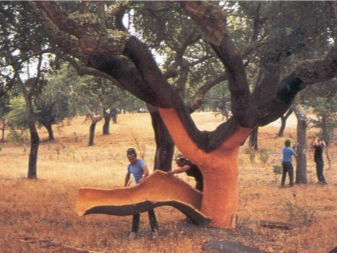

How is the bark removed and does the tree die?

The bark is not removed from a very young tree. The plant must be at least 20 years old. The collection of bark can begin when cracks cover its top layer. They mean that the bark will separate from the tree. One mature tree gives about 2 kg of product.

After removing the bark, the tree does not die. Moreover, if the procedure is performed correctly, it gradually recovers. Over the course of a year, the bark layer grows up to 5–8 mm, and the plug can be removed again in 9–10 years.

An interesting fact: the thick layer of bark is quite easy to peel off. Moreover, if you try to carry out the procedure ahead of time, it will be very difficult to do it. In countries where cork is obtained on an industrial scale, the last digit of the year when the bark was removed is marked on trees after being treated with white paint.

The first time the plug is removed to the height of the trunk 1.5 m from the ground. With each subsequent procedure, the height can be increased by 50-60 cm. It is interesting to know that the bark removed from the oak for the first time will be rather rough, it may not be used for all purposes. The most valuable is the raw material that is obtained during the third and subsequent procedures.

In order not to damage the tree, cutting must be done according to certain rules. Accuracy must be observed in order not to spoil the material itself. There is also a limitation on the quantity: it is allowed to remove up to 70% of the plug. The bark is harvested in summer, when the influence of unfavorable weather factors is minimized.

Work is stopped in the presence of a hot dry wind, as it can dry out the bare trunk, which will severely damage the tree.

To remove the bark, a special hatchet is used, which has a long handle. The first blow is test - the tree should make a characteristic dull sound, which means that it is ready to give up the cork, and you can start working.

-

First, horizontal cuts are made on the tree around the trunk, followed by vertical cuts.

-

Then there is a direct separation of the bark from the trunk - a process that requires extreme caution and quite a lot of effort. The blade of the hatchet must be pushed under the layer of bark and peeled off, using the hatchet as a lever. In no case should the subcrustal layer be damaged, otherwise the cork regeneration process will not begin in the tree.

-

The resulting raw materials are laid out to dry.

How is it processed?

Drying is carried out in an open space under the rays of the sun, it lasts a long time: about six months. When the bark is dry, it is sorted. Suitable raw materials are sent to production for processing, which takes place in several stages.

-

The first stage is heat treatment. Raw materials are steamed and boiled for a long time using disinfectants and other substances to cleanse it, to get rid of the presence of probable insects and parasites. In addition, after such processing, the material straightens and becomes more elastic and durable.

-

Then the product is sorted again. This time, not only the quality of the material obtained is taken into account, but also the thickness of the cork sheets.

-

After that, the bark is kept for another month in a room without access to light.where a certain temperature is maintained.

Depending on the quality, the material is sent to the appropriate industrial plants.

Where is it used?

Oak cork is widely used. Its use in various fields is due to the remarkable properties of the material. Cork is the lightest natural body. It is characterized by a significant decrease in volume under the influence of external pressure. When the load is removed, the volume is partially restored. Other important properties are considered to be low sound and thermal conductivity. And also it is practically impermeable to gases and most liquids, weakly supports combustion.

Many remarkable properties of cork were noticed by people in antiquity. It turned out to be especially valuable material for corking and long-term storage of wine. And nowadays the highest quality product is used to make corks for expensive wines.

In the old days in Portugal, cork was used to make shoes and other products. Today it is also used in the footwear industry, especially in the manufacture of orthopedic footwear. And also cork filler is used by many well-known brands in the manufacture of their models. It adapts well to the characteristics of the foot and has excellent shock absorption.

It should be noted that the use of cork oak bark is practically waste-free production. All residues and trimmings are crushed until crumb is obtained, which is then pressed using adhesives. From the obtained product, blocks are formed, from which layers with different lengths, thicknesses and widths can be cut.

High-tech material is widely used in construction, automotive and other industries.

Pressed cork briquettes are used for the manufacture of wall panels, as they provide excellent thermal insulation, do not require additional efforts when facing. It can also be used as a base for laying parquet or laminate flooring: the elastic structure of the material makes unevenness invisible. The use of expensive material for finishing residential premises is justified: it is environmentally friendly, and therefore absolutely harmless to health. The product is used to produce electrical, sound and thermal insulation gaskets. The cork is suitable for the production of lifebuoys, safety helmets, fishing equipment, kitchen utensils. And also from small waste they create souvenirs, jewelry and caskets.

The comment was sent successfully.