What is tongue-and-groove chipboard and where is it used?

Any construction or even minimal repairs involves work related to leveling the floor, ceiling and walls. Ideally, use a moisture-resistant tongue-and-groove chipboard for this, a distinctive feature of which is resistance to high humidity. As a connection, there are convenient grooves in the extreme parts of the sheets. The main thing is to know the rules of installation and the technology of laying the plates.

Peculiarities

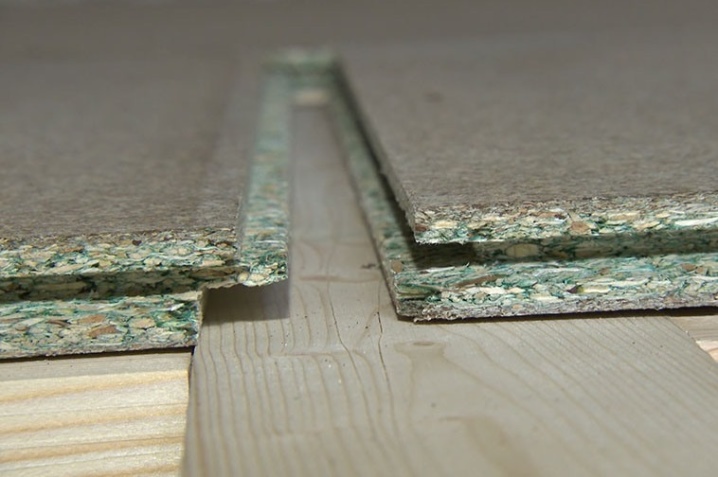

The word "tongue" in translation from German means "Cork". In the construction industry, tongue-and-groove is an unusual type of processing of the edge parts of the panels, two of which are in the form of a groove, and the other two resemble a ridge. When joining the tongue-and-groove structure, the ridge of one sheet falls into the connector of the other. This mount is considered to be very strong and durable.

In the manufacture of grooved chipboard, the method of hot pressing of chips combined with a paraffin and melamine mixture is used. Thus it turns out durable plate with a layered texture. Thanks to this method of creation, the structure of the material is obtained impervious to temperature extremes. That is why it can be used as a base for tiles. The main thing is that all connecting seams are tightly fixed to each other.

Moisture resistant sheet piled chipboard have increased level of strength. They are resistant to various bends, stresses and possible kinks. Due to these characteristics, this material is supposed to be used for both fine and rough installation of any coating. Tongue chipboard panels installed on joists sit firmly on the surface, do not creak. They can withstand heavy weight loads.

If the question concerns the arrangement of the floor covering more than 100 square meters, it is preferable to leave small gaps between the slabs.

Advantages and disadvantages

The tongue-and-groove chipboard, like any other building materials, has a number of advantages and disadvantages. The first is supposed to consider the advantages of cork slabs:

- high density guarantees rigidity and strength of the structure;

- industrial processing of chipboard allows you to get the most even surface of wall, floor and ceiling coverings;

- Convenience and ease of installation, due to which there is no need to call a specialist to install the plates;

- high resistance to humidity helps to install grooved chipboards in rooms with high humidity;

- affordable cost;

- the ability to recycle previously used slabs.

Further, it is proposed to familiarize yourself with some of the shortcomings that still plague grooved chipboards.

- Appearance slabs cannot be called aesthetic, therefore this material is most often used in rough finishing or for hidden work.

- Before purchasing chipboard, you need to look material composition... Some stoves use formaldehyde resins, which are toxic and can harm human health.

- The tongue-and-groove chipboards have a flat, straight surface... Accordingly, it is not possible to use plates for processing curved structures.

Dimensions (edit)

To facilitate the installation of grooved chipboards, manufacturers make and release sheets in different sizes. Slabs with a length of 600 mm are mainly used. But on sale you can find options and larger sizes.

Here is a table of dimensions of grooved chipboards.

Slab format | Thickness |

1830x600 mm | 12 mm |

1830x600 mm | 16 mm |

1830x600 mm | 22 mm |

2440x900 mm | 12 mm |

2440x600 mm | 16 mm |

2440x600 mm | 22 mm |

1200x600 mm | 38 mm |

1830x600 mm | 38 mm |

1830x600 mm | 22 mm |

2440x600 mm | 15 mm |

2440x600 mm | 18 mm |

2440x600 mm | 22 mm |

12mm panels are mainly used for cladding ceilings and walls. For flooring, it is recommended to lay sheets with a thickness of 16-22 mm.

Manufacturers

Today on the construction market you can find grooved chipboards of various manufacturers. Among them, companies such as StroyExpert, SPHERE, Plywood Plus, PlitTorg-S.

Nevertheless, the company QuickDeck is very popular. This is a real construction brand, known in many cities of Russia and neighboring countries. All QuickDeck products have a list of specific features:

- the material is of high quality, high strength, corresponding to European standards;

- tongue-and-groove chipboards of this manufacturer are completely environmentally friendly;

- the front of the plate easily tolerates the effects of ultraviolet radiation;

- the material of this manufacturer has a high level of fire resistance;

- QuickDeck tongue-and-groove chipboards have high-quality sound insulation;

- the outer coating of the sheets does not require special maintenance.

Applications

Moisture-resistant tongue-and-groove chipboards use for leveling walls for finishing, namely: wallpaper or plastic panels. Thanks to tongue-and-groove chipboard, it will be possible to create interior partitions with a high level of strength and reliability. With this material, the ceiling and floor coverings are leveled.

And also sheets of grooved chipboard can be used as finishing of individual structures, for example, boxes and columns.

Selection Tips

Grooved chipboards must have such characteristics as flexural strength, tensile strength and minimal tendency to swell... When it comes to arranging flooring, chipboard sheets should be thicker, at least three-layer. It is best that they consist of 5 layers. For finishing the ceiling and wall floors, tongue-and-groove sheets with a minimum thickness are quite suitable.

Do not forget that another important requirement for the choice of chipboard is the name of the manufacturer. When buying a building material, you should not consider cheaper products from unknown companies.

Let it be a little more expensive, but it will turn out to be a high quality and durable material.

Installation rules

There are several rules for installing grooved chipboards, which must be strictly followed. Otherwise, it will be impossible to make high-quality leveling of surfaces.

It is very important to follow rules for laying flooring, especially if you mount the sheets yourself. It's important not to forget to leave the distance between the slabs and the wall is about 1 cm... To maintain this gap, it is necessary to install special spacers of the required size. The slabs will rest against them. And when the installation is finished, the gaskets are removed.

First of all, logs must be laid on the rough finish. Plates should be laid out along the wall with spikes towards you, and then proceed to the next row. When sheathing the second row, you can use segments from the last and first slabs of an already laid out row. The main thing is that the transverse seams do not coincide with each other, which resembles the brickwork technique.

Before joining the plates, it is necessary to coat them with PVA glue. Then the cotter pin falls into the groove and is additionally fitted with a rubber hammer. After obtaining the required connection, the installed sheets are fixed. To do this, just pick up a screwdriver and self-tapping screws.

It is very important to pay attention to some little things.... To tighten grooved chipboards, you need to pay attention to the black self-tapping screws intended for a wooden base.Their distinguishing feature is the large flat cap. When the self-tapping screw is screwed in, the groove is coated with putty, and after drying it is processed with sandpaper.

On the floor

There are several ways to level the flooring using grooved chipboards: along logs, with rough finishing and expanded clay. When arranging the floor on the logs, it is necessary to lay a waterproofing layer. A polyethylene film can be used as a waterproofing agent, but it is better to consider specialized building materials. The waterproofing strips are overlapped on top of each other. It is advisable that the places of their joints are glued with double-sided tape.... It is important to remember that waterproofing materials must go to the walls and be attached to them. The logs themselves are made of timber, the thickness of which should not be less than 50 mm. If there is a need to improve heat and sound insulation, the distance between the logs must be filled with materials with appropriate characteristics.

However, there is another method that allows you to save on the purchase of log bars. But at the same time, the surface of the rough floor covering should not have protrusions and irregularities. Otherwise, the plates will simply not fall on the surface and will sway. If a lag has already been installed with a long distance, it is recommended to additionally make a crate using small boards up to 25 mm wide.

The second method of laying grooved chipboard involves the use of expanded clay. The floating system turns out to be less expensive, but during installation you will have to adhere to special rules. The floor covering must be dry. Otherwise, the boards will swell, even with moisture resistant properties. The process of work begins in the same way as when installing the floor covering along the logs. Waterproofing is spread on the rough floor, expanded clay is poured on top, then it is leveled using a level. Another waterproofing layer is laid on top of the expanded clay. And on top of it - sheets of chipboard.

If the question concerns the insulation of a concrete floor, it is imperative to use tongue-and-groove chipboards. According to the requirements of the manufacturers, the boards should be mounted on a flat surface. Large protrusions, unevenness of the subfloor need to be cut off, and the depressions need to be covered.

If irregularities are present, but not as global, tongue-and-groove boards can be laid using a thick laminate backing or foam.

On the walls and ceiling

Installation of grooved chipboards on the walls must be done over the rough finish. Initially, a vertical sheathing of boards is attached to the base, the thickness of which reaches 20 cm. Thus, it will be possible to hide irregularities and other flaws in the walls. In places with dips, where the crate is attached, it is necessary to insert lining. When the crate is ready, you can start installing the plates. The long side of the leaf is laid out on the floor, thorn up. Thus, it will be possible to obtain a minimum clearance in the horizontal joint. The installed sheets are fixed with self-tapping screws in a system similar to the fastening of the flooring plates.

It seems to many that the installation of grooved chipboards for leveling the ceiling is a very difficult process. But in fact, this is a misconception. There is no need to install an additional crate, which significantly reduces costs. Fastening of sheets is done with dowels or self-tapping screws. The distance between the fixing elements should be 30-40 cm.

The main thing is not to forget that each joint must be sealed with liquid nails or glue.

It is most convenient to use PVA.

You can learn more about what QuickDeck tongue-and-groove chipboard is in the video below.

The comment was sent successfully.