Screw wood splitters: device, varieties and tips for choosing

To this day, wood-burning stoves work in country houses, which is why such devices as wood splitters are in great demand. They greatly facilitate the process of chopping logs, which is much more difficult and physically difficult by hand.

What it is?

Wood splitters in the country or in a private house solve a rather big problem. It's no secret that chopping wood is a very hard, exhausting physical labor, which, moreover, takes up a lot of time. That is why more and more residents of suburban and rural houses buy wood splitters or make them on their own, using various parts and assemblies from old household appliances and unnecessary machine tools.

Today the industry offers there are two basic varieties of these tools. This is a cleaver and a cone splitter - they differ in the features of the working part. In the first version, it is represented by a sharp, horizontally or vertically located plate, which, under the action of a pusher, pushes and literally cuts the chock. This cleaver is called a rack cleaver.

In the tapered version, the working surface is a special screw thread. Rotating, such a cone cuts into the log according to the principle of a screw and simply splits it into 2-4 parts.

The cone log splitter is characterized by the highest technical and operational qualities., exceptional functionality and ease of use.

Usually, the unit for harvesting firewood in a screw wood splitter has a rather compact size, and if necessary, it can always be moved from one place to another.

A distinctive feature of the cone wood splitter is its truly substantial working life. In the production of such garden tools, exceptionally strong and wear-resistant materials are used, so that it can easily withstand even the most increased loads.

It can be used in a wide variety of climatic and weather conditions, and the wood splitter does not require any special maintenance.

Specifications

Any mechanism that is intended for harvesting wood fuel must certainly meet technical requirements, and this applies to any type of wood splitter: hydraulic, as well as mechanical and conical.

Let us dwell in more detail on the main technical and operational characteristics of the latter:

- optimal working length (distance between wedge and piston part) - 50-55 cm;

- splitting power required for uninterrupted splitting of a wooden blank is at the level of 5-8 tons;

- the rotation speed required to apply force to wood fibers - at least 400 rpm, but not more than 600;

- piston movement - another speed parameter - corresponds to 4 m / s in the forward direction and 7.5 m / s in the opposite direction;

- motor power - 3.4 kW.

For screw log splitters, the option of a travel stop is of particular importance.

The cost of a screw wood splitter starts from 20,000 and reaches 130,000 rubles, while the latter installation is able to split a workpiece of 40 cm in just a couple of seconds.

Design and principle of operation

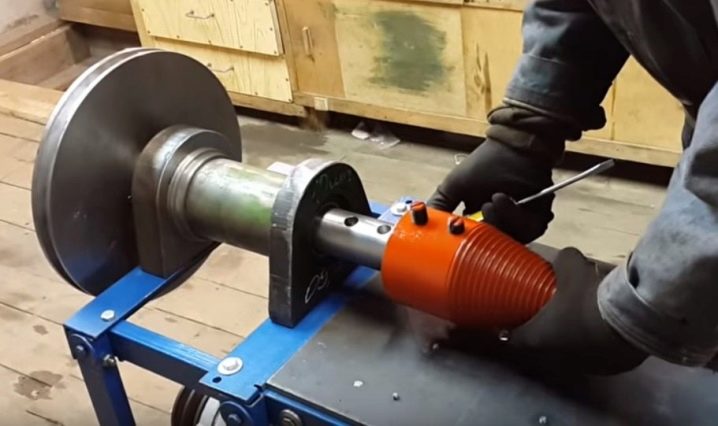

The design features of the cone hole punch are based on the working interaction of a nut and a screw, where soft wood acts as a nut.A gear motor with a tip made in the form of a single or double cone screw is fixed on a solid metal platform. It spins at 250 to 400 rpm.

At the same time, the thrust bar is set in motion from the engine, it pushes the block standing with its end onto the moving cone. As a result, the screw is driven into the side of the workpiece, and the wood is immediately split along its grain.

There are two basic construction schemes for these wood splitters. In the first, a double-threaded cone is attached directly to the shaft of a low-speed electric motor with power parameters of 4-5 kW and a number of revolutions not exceeding 500.

In the second version, two-hand pulleys of several sizes are used, as well as flexible drive straps, while a small pulley is attached to the engine shaft, and a large pulley is attached to the wood splitter shaft.

The simplest of the above mechanisms is considered a wood splitter - it is an elementary diagram without any complex assemblies. It includes a motor, a helical cone, as well as a gearbox, a shaft and two bearings. Moreover, the gearbox can be either factory-made with a gear drive, or chain or variable.

The bearings are directly fixed to the tool in a special steel or cast iron housing, it can be common for both parts or separate for each bearing.

The frame is usually quite strong, assembled from steel pipes or corners, welded together.

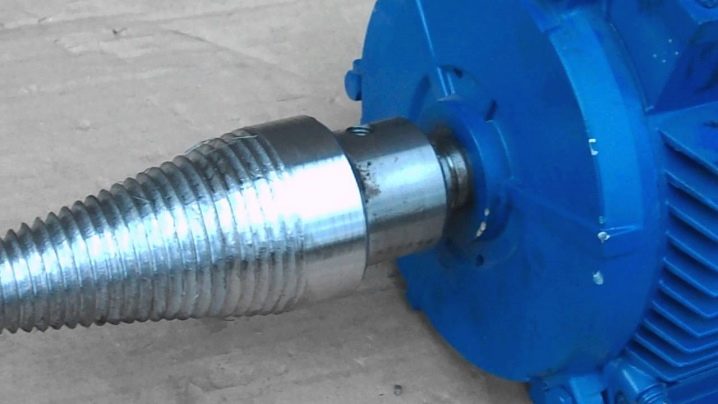

The engine of the screw wood splitter is 220 volts, it is made of dense tool steel, quite hard. It is impossible to make it with your own hands even for an experienced turner at home - it can only be assembled at a factory.

Special attention should be paid to threading, it must necessarily be left-sided, because when screwing a screw into a tree, it must pull the log towards itself, in fact, with the help of threaded notches, a translational movement of the chocks is made.

Advantages and disadvantages

The main advantage of any wood splitter is to minimize the effort required to chop wood. With the purchase of such equipment, you no longer have to bend over, since the unit can be adjusted to suit your height.

If you need to prepare firewood, all you need to do is just turn on the installation and put chocks on it - and the mechanism will do the rest without your participation.

The principle of operation of the cone wood splitter is so simple that even a woman or an elderly person can cope with the work.

The design is quite simple, while the sufficient power is low - no more than 3-4 kW. For home use, a screw with a parameter of 80 mm is enough, and a sufficient installation length is 250 mm. Such products are quite compact and mobile - they can be installed anywhere, and if necessary, they can be moved.

Among the shortcomings, it should be noted a rather low degree of safety and the need to bring wooden blanks on your own. This does not completely exclude the occurrence of fatigue, although it significantly reduces its severity, while significantly accelerating the process of splitting logs.

Views

A conical screw wood splitter is usually performed in a mobile and stationary version. In the latter version, the frame is equipped with an axle with a pair of wheels, due to which the device can be easily moved from the storage location to the log splitting area.

According to the drive method, all screw devices are divided into gasoline, electric, in addition, industrial models can be found on sale, operating due to the rotational movement of the tractor shaft.

Electrical models usually operate on a single-phase network, but there are products that operate on a three-phase network.

But you need to understand that it is quite problematic to bring three phases to your personal plot - it will cost a "tidy" sum, so most homeowners prefer less powerful, but much more practical single-phase options.

Gasoline models are optimal for work in suburban areas remote from the place of connection to the AC network, and besides, in places where electricity is not supplied.

Maintenance of such installations does not require special expenses; they are distinguished by increased functionality and efficiency.

Combined - similar devices work both on electricity and gasoline. They are optimal for domestic use, but are often used in industrial environments.

According to the method of supplying firewood, there are several types of screw wood splitters.

- Horizontal - in this case, the lumps fall into a special groove and move towards the helical cone. There is also a second option, when the log remains in place, and the cutter moves towards it.

- Vertical - in this case, the workpiece is fed in a vertical direction, usually the piercing surface moves to the chock.

- Mixed - these models combine several different types of log feed.

Depending on the configuration, devices are distinguished with and without a replaceable cone.

Top Models

The Splitter cone log splitter is very popular. This technological device allows you to chop logs up to 50 cm in diameter.

The taper screw travel speed varies from 150 to 400 rpm. The plant productivity is 1 cubic meter. m / hour, and the power is 1.5-3 kW.

The unit weighs 90 kg.

The wood splitter-screw "Carrot" is very popular... This mechanism is simple, but at the same time effective, and thanks to the electric principle of operation, such a mechanism can be used in almost any household.

The power of the wood splitter is 2.2 kW, the rotation speed is 3000 rpm.

The working part of the bed has dimensions of 40x70 cm.

The heavy flywheel generates quite powerful kinetic energy, so with the help of the "Carrot" you can fold the most complex logs without stressing the motor. In this case, the splitting of the chocks is so effective that the logs are literally "torn".

However, when splitting logs, the main thing is not to work, since the wood splitter is a rather dangerous structure and can pull the sleeves of your clothes onto its cone in a matter of seconds.

Cone wood splitter "Screw" works according to a simple principle: As the cone rotates, it enters the wood like a screw, splitting it into pieces.

Often, such devices are built on their own. However, when working with this log splitter, basic safety precautions must be followed.

How to choose?

When choosing a factory-made wood splitter, several important parameters should be taken into account.

Impact force is one of the main characteristics that are of fundamental importance when choosing a wire. It is measured in tons, while for domestic use there are more than enough models with a parameter of 5-6 tons. This parameter is enough to quickly chop wood for kindling a bath or a small stove.

In industry, wood splitters with an indicator of 10 tons are used, they are optimal for boiler houses or in large woodworking industries.

To work with large volumes of wood, it is worth choosing models for 12 tons.

Keep in mind that the higher the force, the higher the power should be. Some unscrupulous manufacturers claim that weak motors can create significant splitting forces - this is a hoax. Power parameters less than 3 kW can only be enough for an effort of 4-5 tons.

The choice of parameters such as single-phase or three-phase motors deserves special attention. Three-phase devices are considered more powerful, they require professional wiring with a voltage of 380V. Such devices are optimal for large-scale industries with high intensity of use, but in everyday life it is worth limiting ourselves to single-phase mechanisms. They can be connected to a standard power supply and have built-in surge protection.

An important parameter is the largest size of the log that it can split. This parameter directly depends on the features of the piston stroke. For horizontal mechanisms, it should be no more than 40 cm, for vertical mechanisms - no more than 50 cm.

Pay attention to the presence of a travel stop - this is an optional device and is not available on all models. Such a device allows you to work with short logs, since the mechanism independently blocks their backward movement.

An overview of the range of screw log splitters in the video below.

The comment was sent successfully.