All about manual wood splitters

The process of harvesting firewood requires a fair amount of work: they need to be sawed, chopped, put in a woodshed for drying. Much more effort is expended in chopping the logs. Wood splitters are capable of simplifying and speeding up the process. The market is saturated with them in sufficient volume, but their price is also relatively high. But you can make a simple manual wood splitter with your own hands from scrap metal - a corner, pipes and the like.

Varieties

Some of the most popular firewood cutters are kinetic (manual) devices for preparing firewood that do not require the use of special technical capabilities and function on the basis of elementary physical principles. Basic types in this group:

- spring (functions according to the method of a weighted working element and a large force lever);

- rack (a rack with notches is used in the role of a pushing component);

- with a manual drive (a top-oriented blade with a bedside table, on which a log is placed and, using a sledgehammer or other log, is split into 2 shares without much effort);

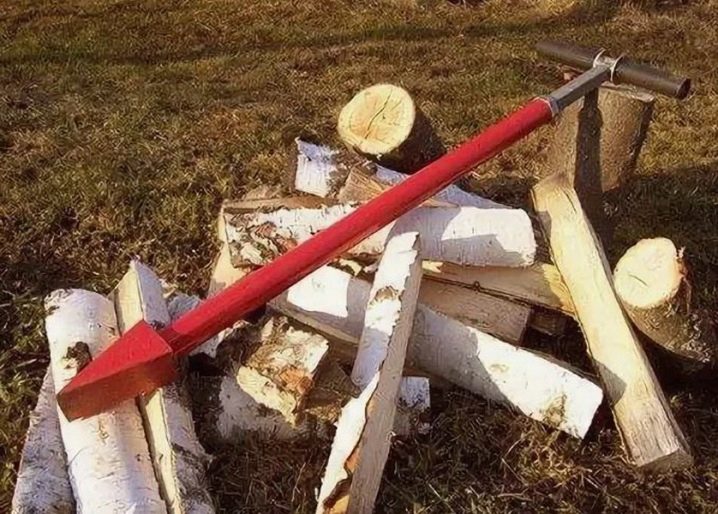

- a cleaver (placed on a block of wood with a cleaver and pricks by means of an internal rod-scrap).

If you are the owner of a cottage or house located outside the city and almost always use firewood for your own needs, then, of course, you have already solved the issues associated with the preparation of the required amount of this fuel for the winter. Hand-held mini-wood splitters Kolundrov, Strela or Greenween are able to simplify all your worries to the maximum., which will help to quickly and at the proper level to split, including damp and gnarled logs. In addition, both ladies and elderly people are quite capable of handling them. When choosing a tool for personal use, you should pay attention to personal requests in the amount of wood harvested and choose non-hazardous and proven devices. Let's consider the above devices in more detail.

Greenween

The device is produced in 2 versions - multifunctional and basic. Their structure is identical - a wide blade made of durable steel, mounted on a frame. Along the edges of the blade, hard plates are fused - ribs. They split the cracked block into pieces. The key difference between the multipurpose and the basic modification of the mini-wood splitter is the diameter of the logs that you can work with. The multifunctional specimen is easy to handle with thick enough logs. It is equipped with a wide plate - a semicircle. The free end of the block is abutted against it.

In the basic modification, the function of the lateral support is performed by a solid iron ring. Its internal dimension sets the maximum thickness of the wood to be split. The carefully designed ergonomics of the devices make working with them easy and effortless. Overall parameters of devices: height - 35 centimeters, diameter - 28 centimeters. The base sample mass is 5.7 kilograms. The multipurpose version weighs 4.8 kilograms.

Arrow

The manual device is intended for chopping logs and not only. It is a mixture of a cleaver and construction scrap. Due to this, it has a wide area of use, not limited to splitting logs. When using it, you can:

- chop wood for a brazier or fireplace;

- loosen dense and frozen soil during construction work;

- knock down ice or ice.

"Strela" has a telescopic design with working and striking elements, which are a long rod with a pointed cone at the bottom and a handle at the top. For splitting logs, the working side of the cone-shaped configuration is placed on a chock in the zone of future dissection. The striking part, which is a weighted rod, rises and falls on the block, splitting it. The fall and rise of the rod is carried out by means of a comfortable rubberized handle. The rubber coated surface prevents the device from slipping in the hand.

The wood splitter can be used for splitting thick, heavy logs. It is quite easy to use and handles very well with soft woody species. Among its other advantages:

- small size;

- versatility (can be used as a cleaver and crowbar);

- reduction of physical work when splitting logs.

Among the key shortcomings of the device:

- the load on the lumbar region remains (due to the need to perform up and down movements with the hands, raising and lowering the impact rod;

- despite the rubber grip, you can get corns;

- great danger of injury - in the process of splitting, the wedge is able to slip off the log, as a rule, when splitting thin chocks, in addition, there is a danger of a chip or log rebound;

- unaesthetic concept.

Kolundrov

An order of magnitude safer alternative and the likeness of "Strela" - a typical manual wood splitter Kolundrov. In addition to good performance, it has a nice appearance (in the trade there are modifications with artistic viscous and patina, which are literally works of art). Moreover, it is completely safe to operate. The stable lower part has technological holes for fixing the device on the plane, and the iron ring at the top holds the broken logs and chips, preventing them from flying to the side and causing unexpected injury. Sharpened knives can easily and effortlessly break into pieces even damp and heavily knotted logs.

Spring loaded

One of the optimal and economical options, which can become a reliable device for harvesting firewood, distinguished by its simplicity of structure, strength, economy and reasonable cost, is a spring log splitter. This type of wood splitter is an evolutionary step in the improvement of traditional cleavers. The operation of the spring device involves the use of muscle force, but to a lesser extent due to the spring mechanism, large lever and auxiliary weight.

The structure of such a homemade product includes an iron pipe or profile (this will become our lever, increasing the strength, with a knife at the end), a metal stand and a hinge joint between them. The spring-type return mechanism can be made using a used shock absorber.

DIY creation

Buying an industrial wood splitter is not always economically feasible, because individual varieties of this device can be assembled independently from ordinary materials. You can make it using ready-made drawings and instructions. Dimensions and dimensions can be changed based on operating conditions. To make it, you will need the following materials:

- channel;

- I-profile;

- corner or pipes for the bed and stiffeners;

- metal corner;

- square tube;

- automobile suspension spring;

- a piece of pipe in diameter is slightly smaller than the diameter of the spring;

- hinge knot;

- cleaver;

- weighting agent (a piece of a channel with a thick shelf or rail).

For a stationary installation, you can pour a concrete foundation by installing a rack in it. With this design, the frame does not need to be assembled. All elements of the wood splitter, with the exception of the hinge joint, are connected by means of electric welding.Pieces of the channel for the frame and the I-beam for the base are cut off. The length of the rack is 0.6-1 meters. The height of the base is adjusted separately. The support is connected to the bed, precisely, without deviations, observing a right angle. For stability of the installation, pipes are welded to the ends of the bed in a horizontal position. The conjugation of the frame and the base is reinforced with spacers.

The platform for the spring is a piece of channel with a size of 40-50 centimeters. A hole is cut out from one of its edges by means of an angle grinder for alignment with the base. A spring guide is welded to the second end. To calculate the platform fixation zone, it is necessary to subtract the size of the spring from the height of the rack. The platform additionally needs to be reinforced with spacers from the corner.

In the upper region of the base, a place for a fit with a depth of 8-10 cm is cut out for the outer component of the hinge assembly. Next, a channel is prepared for a cleaver. For this purpose, a rectangular hole of such length is cut on one side of a channel with a size of 0.5-0.7 meters at a distance of 10-15 centimeters from the end so that the base beam does not interfere with the movement of the channel that is put on it. In the middle of the hole, the axis of the hinge assembly is welded. At the other end of the channel, a place for the spring to be seated is fixed.

The distance from the base to the upper and lower spring cups should be equal. A cleaver is boiled to one edge of the iron square at the bottom at a right angle, and a device for weighting is on top. The other edge is connected to the cleaver channel so that the total length of the resulting lever is 1-1.5 meters. The assembled installation is strung on the base in such a way that the external components of the swivel joint go into the place for landing on the beam, securing them with electric welding. A spring is strung onto the landing cups. For practical use, the handle is fixed next to the cleaver.

To make the self-made device mobile, 2 wheels are installed on the bed from the base side.

For information on how to make a spring wood splitter with your own hands, see the next video.

The comment was sent successfully.