Hydraulic wood splitter: features and tips for choosing

Hydraulic wood splitters are indispensable helpers in the wood harvesting process. They allow you to quickly and efficiently handle large volumes of wood. The device is very popular both among the population and in the professional environment, due to its consumer availability, ease of use and ease of maintenance.

Features and purpose

The hydraulic log splitter is a mechanical splitter used for splitting logs of any thickness and moisture content. The tool allows you to mechanize heavy manual work and provides the maximum reduction in labor costs. The main purpose of the wood splitter is to split the chock into several parts, and additional refinement with an ax is not required after that: the logs are obtained in the desired shape and size and can be immediately sent to the firebox.

A large number of positive reviews and a high demand for wood splitters are explained by the following obvious advantages of this tool:

- when working with the unit, a person does not have to bend low and strain his back, which allows using the wood splitter to all categories of the population, including women and the elderly;

- the units have a very high productivity and are able to cope with such a volume of wood in 2-3 hours, which took at least a week to process with an ax;

- the device very rarely breaks down and is highly maintainable, which is explained by its simple design and the absence of complex components and assemblies;

- working with a wood splitter is completely safe - for this you just need to read the operating instructions and follow the recommendations given there;

- a wide range of models and the availability of budget samples greatly simplify the choice and make the wood splitter even more affordable;

- working with the device does not require certain technical skills and great physical efforts, which favorably distinguishes it from an ax, when working with which good dexterity is required.

Along with the obvious advantages, the hydraulic wood splitter still has weaknesses. The disadvantages include the large dimensions of professional models and their high energy consumption. In addition, some household samples are difficult to cope with durable and too hard wood, which often leads to the need to use a traditional cleaver.

Specifications

The main technical parameters of hydraulic wood splitter are the type of drive, mobility, pressure on the wood and possibly the permissible diameter and length of the workpieces. It is worth familiarizing yourself with them in more detail.

- The piston pressure on the log is on average 100-200 bar, which in power equivalent corresponds to 50-60 kN. This value is not the same for all models and varies depending on their capacity.

- According to their mobile characteristics, the machines are divided into portable and stationary. Moreover, some industrial designs are made in the form of a trailer to a car or tractor, and household models are equipped with wide and comfortable wheels.

- The drive type is one of the main technical parameters and affects the functionality of the model and its operating conditions. There are two types of drives: electric and gasoline (diesel).The latter is considered more powerful in comparison with the electric version and is more often installed on industrial models. Devices with an electric motor are used in garages or summer cottages and are characterized by the absence of harmful emissions into the environment and the ability to work indoors. Such units operate from a power source of 220 and 380 V.

- The maximum allowable workpiece diameter is usually indicated in the accompanying documentation. It is 350 mm for household models, and up to 500 mm for professional ones.

- The split length also varies depending on the model. In low-power electrical devices, it does not exceed 52 cm. Industrial designs are often equipped with a length regulator and are capable of splitting over 1 meter in length.

Important! The cost of wood splitters also varies - it starts from 10,000 rubles for models for private use and goes up to 500,000 for industrial designs.

Design and principle of operation

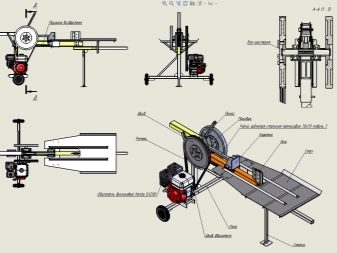

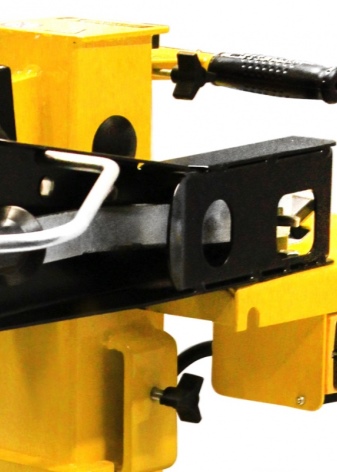

The hydraulic wood splitter consists of a frame, a stop, a hydraulic cylinder, a working blade, a pump, a fluid pressure distributor, an oil tank and an engine. The engine starts the hydraulic pump, which causes the piston to move. The knife plays the role of a cleaver and, under the influence of pressure, splits the workpiece. The chock is placed on a metal frame between the knife and the piston.

A distinctive feature of hydraulic devices from conventional mechanical devices is a smooth increase in force, if there is a shortage of which, the cylinder stops moving and does not force the engine to work at high speeds. In mechanical models, a smooth increase in force does not occur. If the chock does not crack, the motor will still run at full power, which leads to overheating of the engine and increases the risk of premature wear. On hydraulic models, if the cutter is unable to split the wood, the piston stops and the engine slows down and does not overheat.

Views

The classification of hydraulic wood splitters is based on several criteria. The first of these is the functional accessory of the instrument. According to this criterion, two types of devices are distinguished.

- Professional. They are represented by complex dimensional models that, in addition to splitting logs, have a number of useful functions. Such units are capable of feeding, trimming and even unloading firewood, which makes them versatile in logging production and allows them to replace several highly specialized machines at once. The devices are equipped with a powerful gasoline or diesel engine, and the hydraulic system is often supplied from the tractor PTO shaft. Professional models have a very high cutting speed and are able to easily cope with old and damp wood. Due to this, they are used for harvesting and mechanical crosscutting of timber at large logging points.

- Household. Such wood splitters are intended for private use and cannot cope with large volumes of wood. Such devices are often equipped with a not very powerful electric motor. The advantages of electro-hydraulic models are high mobility, small dimensions and low weight. The disadvantages include not a very large motor resource and restrictions on the size of the workpieces.

The next criterion for distinguishing wood splitters is the way the logs are laid. On this basis, there are three categories of devices.

- Horizontal models are designed to be placed and split horizontally. Such devices represent the most numerous category of devices and are widely available for sale. The operation of such units can be performed in two ways. In the first case, the blade is motionlessly fixed in the bed, while the piston powerfully pushes the workpiece onto the knife. In the second version, the log is stationary, and the hydraulic drive moves the knife on it no less powerfully.

- Vertical devices have a mechanism absolutely identical to horizontal devices and differ from them only in its location in space. The chock is installed in a special gutter in a vertical position, after which it also splits vertically. In this case, the movement of the knife occurs from the bottom up. Vertical devices have a rather compact size and are very convenient for storage.

- Mixed models include both ways of laying chocks. They are classified as professional equipment. Such devices are characterized by high performance and are used in large logging enterprises.

Rating of the best models

The modern woodworking equipment market offers a huge number of both imported and Russian samples of hydraulic wood splitter. Below is an overview of the most popular models.

- Domestic gasoline model "Gorynych 6T" it is characterized by high productivity and a fast stroke of the working piston, in which each of the cycles lasts no more than 2.5 seconds. The device is designed for industrial volumes of logging and belongs to the category of professional equipment. In an hour, a wood splitter is able to split up to 50 blanks, which, with an average size of 20x20x40 cm, corresponds to six cubic meters of wood per hour. The unit is perfectly adapted to Russian climatic conditions and can be operated at temperatures from -30 to +30 degrees. The knife blade is made of high-strength steel and can work for a long time without sharpening. All parts of the unit are coated with an anti-corrosion compound, which makes the device resistant to rust and decay. The cost of such equipment is 120 thousand rubles. In addition to models with gasoline engines, electric devices for household use are also produced under the Gorynych brand.

- In second place is the Chinese-made model. Champion LSV6000... The device is equipped with an electric motor and operates on a 220 V mains. The kit includes an additional attachment for the blade for splitting the wood into 4 pieces, which significantly reduces the period for preparing firewood. The device is designed for vertical laying of logs and is intended for mass use. The motor power is 2.7 kW, and the applied force is equivalent to 6 tons. The unit is capable of working with lumps with a diameter of up to 300 mm and a length of up to 1000 mm. The product is completely safe, very easy to use and weighs 97 kg. The price of Champion LSV6000 from different suppliers is slightly different, but on average it is about 38 thousand rubles.

- The third line of the popularity rating is occupied by a Danish device. Texas 520 H worth 20 thousand rubles. The model is equipped with a 1.5 kW electric motor, has a modest size and weighs only 46 kg. The maximum permissible size of chocks is 25x25x50 cm, and the maximum effort is equivalent to 5 tons. The device is designed for horizontal loading, is absolutely safe to use and has a long service life.

- The model is also in no less demand. Lancman SL10produced by the Slovenian company Gomark. The device is characterized by high strength and durability. It is capable of running on both gasoline and electricity. In addition, the devices can be connected to the power take-off shaft of tractors and are used for industrial purposes. The engine power is 4 kW, which corresponds to 6.5 hp. with. The maximum force is equivalent to a weight of 10 tons, and the weight of the device reaches 275 kg. The device has a horizontal type of logs and can work with workpieces up to 65 cm in diameter and up to half a meter long. This model costs 222,400 rubles.

How to choose?

Before proceeding with the purchase of a hydraulic wood splitter, you need to decide on the purpose and functionality of the model.So, if a product is bought for a private household and will be used to prepare firewood for one, maximum two families, then it is better to opt for a simple horizontal model with an electric motor, or even completely make the device yourself. Home-made devices are often equipped with unpretentious Linde hydraulic pumps and an electric motor is installed on them. If the unit is necessary for professional activities on an industrial scale, then the best option would be a serious device with a power of at least 2.5 kW. For processing large volumes of wood, a 4 kW petrol or diesel model with a set of options, two-speed drive and the ability to connect to the tractor PTO shaft is a good choice.

For an overview of the AL-KO KHS 5200 hydraulic log splitter, see the following video.

The comment was sent successfully.