Types of wood wax and the nuances of its choice

Wood is vulnerable to moisture, fungus, parasites. A special wax is used to protect it. From the material in this article, you will learn what it is, what it happens, how to choose and use it correctly.

What it is?

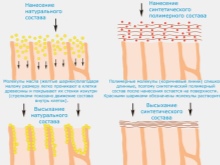

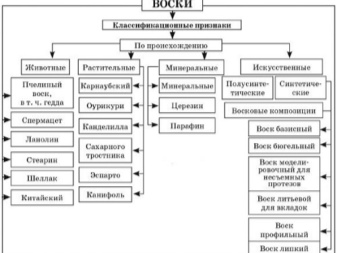

Wood wax is an environmentally friendly natural material. It belongs to classical lipids and is nothing more than an ester of higher organic acids and higher monohydric alcohols. It contains paraffin, free acids, aromatic compounds, dyes. Its components can be additives of inorganic origin, beeswax, oils. Depending on the variety, the composition, plasticity and characteristics vary. It is used immediately after opening the package. Makes the treated surface smooth, aesthetically pleasing.

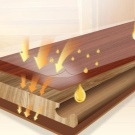

It happens transparent, tinted, light beige, yellowish... It mixes well, thanks to which you can create new tones, get dark and light shades. It is used for processing facades, arbors, fences, small architectural forms. Possesses resistance to destruction associated with negative environmental factors. Retains wood fibers, is a vapor-permeable protective agent.

Does not create a film layer on the surface. It is the best alternative to varnish. Non-toxic, completely safe for health. Does not provoke allergic reactions, does not change the processed wood structure. Easy to use, together with the color scheme, it refines the color of the material. Unlike many impregnations, it protects the tree not only outside, but also inside. Inert to water, dampness, temperature extremes.

It is a sealant for wood, prevention of rotting, abrasion, stains. Makes wood water-repellent, resistant to scratches and other mechanical damage. The protective wax is fireproof and effective in application. It provides long-term protection of the material, while re-processing is only necessary in case of repair in a damaged area.

The wax perfectly penetrates the fibers, fills microcracks. They are used to restore wooden furniture, doors, parquet, and wall panels. It is used to protect roofs, timber battens, ceilings, floors.

Views

Based on the form of release and characteristics, several varieties of wood wax are distinguished. The consistency of the products can be soft, pasty and hard. The effectiveness and approach to application depends on this.

On sale there are varieties with linseed oil, water-based wood products. Popular products are oil-wax impregnation, tinting decorative wax, white, matt transparent.

For each type of damage and amount of work, a different type of wax is used. Liquid varieties are applied with a brush, as in classic staining. Rub hard products into the surface to be restored.

Solid

Varieties of this group are more popular than others, despite the fact that they are more difficult to apply. Visually similar to multi-colored plasticine, they are made on the basis of vegetable oils and natural wax. They are supplemented with chemical components, therefore, they are heated before processing. They are used for sealing large cracks and chips.Wax of this group is suitable for outdoor and indoor work at an air temperature of +10 to +25 degrees.

The products perfectly restore the integrity of the surface, enhance its shine. They are especially flexible and have high adhesion. They are considered universal waxing products. Cope with the processing of bases of any type. Forms a high quality protective layer.

They require maximum care in application. When the surface is uneven, it is practically impossible to level. In this case, the risk of processing with obvious differences in shades is likely.

Soft

Soft wax products include natural-based products.... Their protective effect will be the weakest. But they have deeper penetration. If we compare them with other analogues, then soft products remain sticky longer, melt better. However, they do not increase the antistatic properties of the treated products. Therefore, waxed wood is excellent at attracting dust. She also needs periodic coverage updates. If the temperature exceeds 20 degrees, then the density of the wax decreases.

Soft oily impregnations renew the array, visually masking chips and dents. They contain no aggressive solvents and benzene. The lower the percentage of the dissolving component, the faster the solution dries.

Liquid

Wax with a liquid consistency is good for its penetrating power. Penetrates into hard-to-reach places, can create a uniform protective layer even on complex threads. Has a pleasant smell, makes the wood invulnerable to moisture. It contains artificial suspensions that maintain the desired consistency. Liquid wax fills in scratches and crevices and has synthetic inclusions. It is used when processing large areas (panels, floors).

It is easy to use, has a matt and gloss level... Due to this, the level of slipperiness of the surface also varies. It is applied to the surface with a brush or a regular paint roller with a soft coat. To get rid of excess, a lint-free cloth is used. However, there are practically no smudges during application, since the product dries quickly.

Colored

The inclusion in the composition of a colored dye does not change the properties of the wax. Due to the product, it is possible to restore the original shade of wooden products, to hide small defects (for example, scratches). Wax paint has many shades in the palette, allowing you to choose the most suitable color. It is used for restoration, it is black, brown, golden, red, amber.

These types of wax are not used for coating tabletops, chairs, armrests due to the ability of the pigment used to stain. However, they perfectly equalize the color, create a uniform thin film.

Popular manufacturers

Various domestic and foreign brands are engaged in the production of wood processing waxes. The rating of the best companies includes several brands, selected according to customer reviews on various Internet portals.

Borma holzwachs

Italian supplier of environmentally friendly raw materials for the processing of various elements of classic and garden furniture (countertops, furniture facades), wooden floors, terraces... It produces products of the usual and pigmented type with parquet oil, compositions for saunas and baths with interlayer drying in 6-8 hours and a consumption rate of 1-2 layers.

Osmo

German manufacturer of anti-allergenic wax impregnations with a barely noticeable vegetable odor, intended for indoor and outdoor use. The range includes solid products for countertops, colorless waxes for floors, terraces and furniture for gardens, balconies, doorways and windows.

The brand's products give a glossy finish, resistant to household chemicals. Differs in a small consumption per 1 m2, assumes drying between layers in 10 hours. Gives a colorless, silky finish with a matting effect.

Biofa

A German brand specializing in the production of sustainable materials for wood processing. Produces a wide range of decorative and care compositions. It produces oils with wax and color, impregnation with an antiseptic.

The products are in demand due to the ease of application, suitable for domestic and professional use. Designed for interior wood finishing, with the exception of floors and work bases. Possesses bactericidal properties and antistatic effect, assumes 2 layers of application.

Rustins

British company supplying to the domestic market water-based products and waxes with white spirit. Depending on the variety, the products are intended for indoor and outdoor use (including fences, awnings, doors, cutting boards).

The brand's products dry quickly, differ in a weak smell, dullness, colorlessness, they are semi-glossy, satin. Apply in 3 layers with drying in 4-6 hours. They have an average consumption per 1 sq. m. Suitable for processing an array that has not been previously finished with other materials.

Rubio monocoat

Belgian manufacturer for single coat products... Produces oil-wax impregnations with interlayer drying in 3-5 hours and minimum material consumption. The range includes compounds for indoor and outdoor use, designed for all wood surfaces. The products are designed to process large areas in a minimum of time. It is more expensive than its counterparts in its segment.

Prevents cracking of the finished solid wood, its rotting and damage by harmful insects.

Tikkurila

Produces wax-containing impregnating materials in a small range. The brand has 2 lines of products: Valtti (impregnation for terraces and garden furniture) and Supi (coverings for strengthening the logs of the bath and sauna).

The company's products may have an oily odor. They cope with the processing of staircases, furniture ends. They create a uniform wax layer, apply in 1-2 layers with an average drying of 4 hours and have a budget cost.

"Sigma-Universal"

These are products represented by wax oils for various purposes. Based on the variety, it is intended to protect wood inside baths and saunas. Suitable for walls, ceilings, dressing rooms, dressing rooms, furniture decor. The products can be used for building facades, gazebos, fences, attics, mansard walls and other foundations, as well as for covering wooden elements of weapons. They have a low price for 1 liter. Some formulations are designed to cover surfaces subject to high stress (stairs, floors, hallways).

Which product is better, the buyer decides on his own based on his own preferences, the available budget and the type of planned work. For example, Osmo products are completely safe and can be used to cover baby cots and work surfaces. Someone likes beeswax more, while others choose products with synthetic suspensions.

The manufacturer Rubio Monocoat, whose impregnations give a high processing result, has also proven itself very well.

Secrets of choice

When buying a particular type of wood wax, you need to consider a number of criteria. The key one is the purpose, which is indicated on the label. It will allow you to select the composition as accurately as possible. Compositions for baths and saunas differ from impregnations intended for facades of buildings and garden furniture. On sale there are varieties for impregnating parquet, as well as materials that are more suitable for flooring.

High-quality material has an oil (linseed, soy, sunflower) or linseed oil base. It is the oil that determines the depth of the penetrating layer. It creates a hydrophobic protection, ennobles the woody texture. It is desirable that the composition contains hard wax (carnauba, candelilla).Its indicators of wear resistance and water resistance are much higher than that of other varieties. The gloss level depends on the proportions of the components used.

The best wax should contain driers. They accelerate drying, are responsible for the hardening of oily components. Thanks to them, the coating dries not only quickly, but also evenly. In addition to oil, organic substances and water can be solvents. Varieties for outdoor use must contain mineral pigments. This increases the light sensitivity of the material. In addition, the composition should include natural oil (soybean, walnut, rapeseed).

For some, smell is a significant purchase criterion. It can be caustic. However, if the smell is strong, this does not mean that the quality of the impregnation is poor. Common foods smell like oil or wax. The amount of material is selected based on the planned work. If the wood is not prepared, it absorbs oil more. In addition, a lot depends on the density of the array and the effect you want to achieve. These coatings may require 3 to 5 coats. However, 1-layer formulations are not suitable for this. They will create a protective film from the first layer. Subsequent coats will have no visible effect and will not enhance the gloss.

When choosing a specific type of impregnation, pay attention to the type of array. Products for processing hardwood, exotic, softwood vary.

How to apply correctly?

The use of different types of wax has its own nuances. In order to prevent deformation, the wax is supplemented with white spirit. Before proceeding with the application of the product, prepare the surface of the object to be treated. Proper surface preparation involves the elimination of irregularities, dirt, dust. Any inclusions of varnish are cleaned off with a blade or knife. After stripping, they pass along the base with sandpaper (fine abrasive emery cloth). Dry the material if necessary. Depending on the volume of solid particles in the wax, the number of layers applied may vary. Complete drying is required after each layer. The wax takes a long time to dry at room temperature.

To level the dried coating, use a special trowel (rounded board). The obligatory stage of waxing is final polishing. It is carried out by means of a rotating brush. Thanks to this tool, the surface heats up, and the wood acquires a beautiful gloss. Now let's look at how to treat wood substrates, depending on the type of wax.

The solid composition is applied after the preparation of the necessary tools and materials. For work, you need a grinder, wax impregnation itself, a tin container, a brush, a woolen or cloth rag. After surface preparation, the wax is melted by means of a water bath. The heated liquid mass is applied to the wood. The product is pressed with a spatula or rubbed with a soft cloth in the direction of the wood fibers. Then leave to dry completely, remove excess material. Next, sanding and polishing with a cotton napkin is performed. Deep damage requires several layers of wax.

It is easier to process wood with liquid wax. Manufacturers recommend applying it as follows. The old varnish coating is removed from the surface. Take a roller or brush, apply the first layer of wax. Reapply after about 2 hours. After achieving the desired result, sanding is performed. For this, use a soft cloth. When polished, the coating will acquire the desired gloss intensity. The longer the wood is processed, the more glossy it will turn out. The technique of applying a colored product does not differ from the previous one. However, when going to cover the array with any type of product, you need to take into account that it will not protect the tree from liquids containing alcohol.

In addition, it will not be able to cover spots that have appeared from water or sunlight.

If, after the distribution of the composition, swelling of the upper layer is noted, it is necessary to walk along the base with a dry cloth. This will remove the roughness and return the fibers to their original position. The final drying time is difficult to determine. It depends on various factors (composition of the product, temperature conditions, humidity level). The topcoat may take 2-3 weeks to build up strength. Sometimes sanding, degreasing, priming of the surface are performed before waxing. The composition will fill small pores. After that, they are passed along the base with fine sandpaper.

Spread the wax paste over the surface with a cotton swab in a circular motion. The processing is carried out in several layers, rubbing the paste along the fibers. If the product does not work well, heat it slightly. Surfaces subject to the greatest friction are coated with special compounds. These areas have to be re-treated more often as they lose their protective layer over time. For toys, walls and ceilings, they try to use colored compounds with carnauba and beeswax.

Subsequent care of surfaces

Let's consider a few rules for effective care of a waxed surface.

- It is not recommended to use the product for several days after finishing. This can be accelerated by ventilating the room.

- The protective properties of wax are different from varnish... Surface waxing is more decorative. Therefore, the basic rules of care are to be handled with care.

- You can not check the processed solid wood for strength, you can not deliberately spoil the base. Do not wax surfaces near high temperatures, otherwise the material will simply float.

- If alcohol accidentally spills onto the surface, wipe the base dry immediately.... Otherwise, the appearance of stains cannot be avoided. Do not wipe the surface too often with a damp cloth. Over time, this will wear off the protective layer.

- Do not wipe the bases with products containing abrasive particles. Due to such manipulations, there is an urgent need for re-waxing.

- To prolong the aesthetics of waxed items, do not forget about regular wiping with a dry cloth.... If the need arises to get rid of contamination, you can use alcohol-free products or wax products.

- You can preserve decorativeness by using special wax fixing agents sold in the form of aerosols.... The formulations contain natural resins, thanks to which an additional layer of protection is created. These concentrates remove dirt and stains from coloring foods and beverages without washing out oil and wax. You can also use wax products. They enhance the tarnished appearance of the surface and extend the service life of wood products.

Subject to the rules of care, the treated surface will not need restoration for at least 5 years.

The comment was sent successfully.