All about stabilized wood

There is no need to talk about the value and demand for wood in repair and construction - almost everyone has encountered this. There are areas where wood, a natural and excellent material in many respects, needs to be slightly modernized. Or rather, to enhance its operational properties. One of these transformation technologies is wood stabilization.

What it is?

Stabilization is a special type of material processing in which its pores are filled with special protective compounds. First of all, these actions are aimed at increasing the decorative properties of the tree - so that these properties remain unchanged for as long as possible. But at the same time, the indicators of the hardness of the material increase, as well as the resistance to the influence of external factors.

The process itself is quite laborious and not very fast. It requires a responsible attitude and certain knowledge. On an industrial scale, it is not very rational to use this method, but for small individual work it is largely indispensable. Stabilization is suitable for changing the characteristics of furniture, wooden crafts and toys, various interior items, knife handles.

Initially, stabilization was done to keep the tree dry. But gradually decorative purposes came to the fore. As soon as it became clear that in one fell swoop it was possible to change both the appearance of the tree and its operational profile, processing began to be used more actively.

What is it for?

This procedure changes the material in several directions at once. And it often saves money and efforts of a master who could achieve the same goals using several costly technologies at once. Wood stabilization is used for the following purposes:

- the tree becomes hard and dense;

- the resistance of the material to moisture increases, as does the resistance to thermal drops and exposure to sunlight;

- the tree ceases to be so vulnerable to ignition, stabilization becomes a barrier for paints and varnishes;

- chemical and biological effects on the material are also neutralized, deformations and rotting cease to be obvious threats to wood;

- the material becomes more aesthetic and decorative;

- wood is more ready for manual and mechanical processing after stabilization.

Obviously, the consumer qualities of the material change significantly. This is not just a surface impregnation, a primer, it is filling the maximum pore volume. Such a procedure is valuable for the handle of a knife, for example, which not only constantly interacts with water, but is also in contact with steam, hot objects and substances. The wood becomes thermally stabilized, which means that its service life increases.

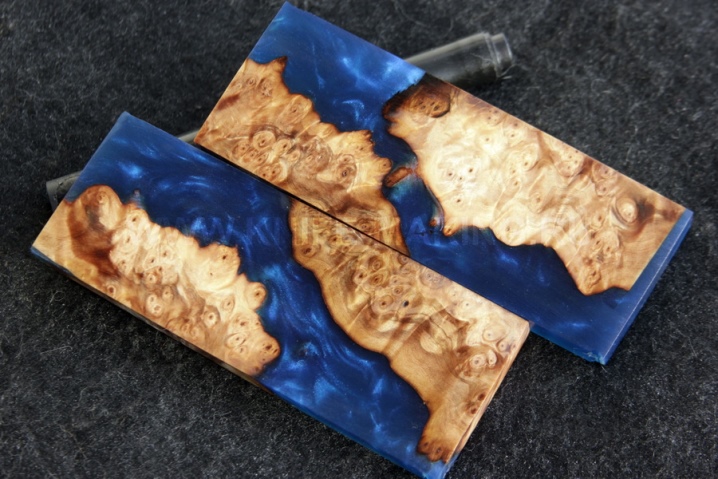

By the way, after the procedure, the material looks more like a natural stone rather than wood. The cut pattern of such wood is very similar to the pattern of marble. And it is really beautiful.

Views

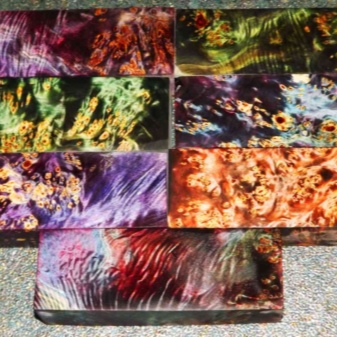

Most often the tree is stabilized in two colors. This is more common, and the result is predictable. But if two-color stabilization seems like something simple, technologies are also applied. multicolor stabilization... They are more complex, and it will be difficult for beginners to cope with this task. In addition, this type is more often used for decorative purposes, that is, we are not talking about the strength and increasing the operational properties of the tree (they are not priority). But how exactly to achieve a change in the material is a question with many alternatives.

Stabilization methods

There are a lot of effective means for this purpose: from epoxy resin to birch sap.

Cold impregnation

This method can be called the most affordable, it is used when dealing with small wooden blanks... It is in the cold composition that the wood will be soaked. And this process will take at least 3 days (and in general it can reach 2 weeks). The soaking time depends on the selected raw material. A striking example of such a remedy is linseed oil.

Features of the process of impregnation with linseed oil are as follows.

- The composition penetrates deep into the pores, dries up, forming a polymer that is not afraid of decay. Technically, impregnation can be superficial, by dipping and using a vacuum installation.

- The tree is impregnated in several layers (the first is usually oil diluted with turpentine), each new layer is applied strictly after the previous one has dried.

- The oil will dry for about a week, but the process can be accelerated.

The same composition can be used in different ways. So, for the next type of impregnation (hot), the oil can be boiled.

Hot impregnation

This option is more complicated, it is more often used to change the properties of bulk wooden products. The process takes 2-3 days, the penetration will be deeper. This is exactly aging or even digestion in hot formulations, since it is in this form that they are more fluid.

As a result, polymerization is more efficient.

Vacuum treatment

To implement this method, a vacuum chamber is required. Pumping air out of it removes the liquid from the wood. Later the master feeds the stabilization solution into the chamber, and it fills the opened pores of the wood.

Pressure treatment

This method is very similar to the one described above, but there is a significant difference. Wood preservation in this case can be achieved through high pressure. The wooden blank is sent to a container with a special composition, installed in the chamber. High pressure helps to expel air from the pores, and a pre-selected composition for polymerization penetrates into the voids.

What is required?

There are so many options for which composition to use. Consider the most popular tools for polymerization.

Saline solution

Salt is the cheapest and most readily available wood stabilizer. Take a tablespoon of the most common table salt of absolutely any grind, dilute it in 1 liter of water, boil a piece of wood in this composition for about 3 hours.

Not to say that this option is especially practical, but sometimes it is also used.

Drying oil

Good composition for stabilizing wood crafts. Since it contains vegetable oils that have already been heat-treated, it provides the wood with both moisture resistance and fearlessness in front of the sun's rays.

And to make the varnish viscosity sufficient for work, a solvent is added to it.

Birch juice

This eco-friendly stabilizer does not have any harmful components in its composition, for which we are loved by many craftsmen. It manifests itself most clearly in a vacuum chamber; subsequently, the processed product requires good drying at high temperatures.

Epoxy resin

It is used for different types of wood with the exception of conifers. Even before impregnation, the master must make sure that the fluidity of the composition is satisfactory. An alcoholic solution of resin is used more often, however, it is not at all easy to prepare it yourself.

Liquid glass

This is a fairly popular household solution, which, after being applied to a tree, forms a kind of protective film on the latter. Usually, various decorative wood products are treated with such a tool.

The solution along the way protects the object from fungus, decay.

Polymer liquids

These products have high penetrating power, and natural polymerization occurs quickly. Among the most popular formulations is Anakrol-90. It is only used in a vacuum chamber. It is a polyester impregnation that transforms into a thermosetting polymer. After such treatment, the tree loses its vulnerability to strong impacts and various aggressive external factors.

Another product from the same series is “100therm”. It is a clear, medium viscosity liquid.

"Buravid"

The polymer product is taken out separately due to its high popularity. It is a product with optical pigments, which are responsible for the polymerization of wood. The viscosity of the product is not too high, therefore it penetrates even into hard-to-reach places. The composition prevents biological contamination of wood products. They also love it because it favorably emphasizes the natural pattern of wood, showing all the natural beauty of the fibers.

"Pentacryl"

Another polymer. Dyes and pigments on a fat-soluble basis are added to it. That's why products treated with this solution become more expressive, richer.

The composition is convenient for home use.

Oil impregnation has already been discussed. In addition to linseed, nut, cedar, and tung oils are used. Which method to prefer is a matter of individual choice: someone decides to process natural material only with the same natural products, someone thinks that an industrial polymer copes with its task flawlessly. But it is important not only to choose the right composition, but also to use it correctly.

How to do it at home?

The following instructions will tell you exactly how to turn an ordinary tree into a more beautiful and stable one with your own hands.

Wood processing with Anakrol polymer.

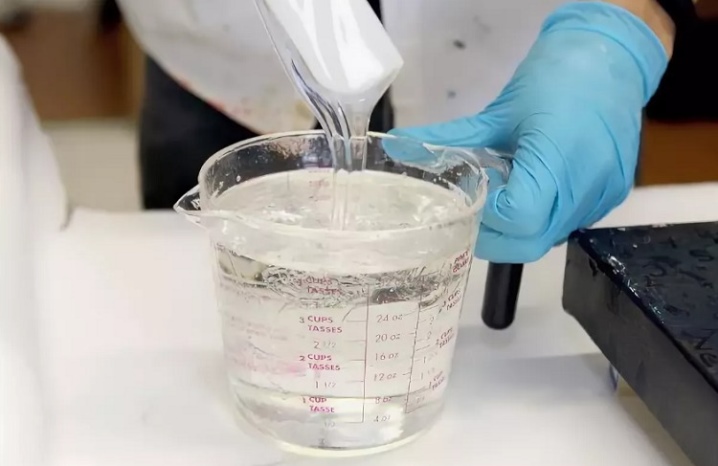

- First you need to prepare a container in which the workpiece will be placed. The container is filled with the selected composition so that the product can sink in it.

- Then it is necessary to create such conditions for a vacuum so that air bubbles cease to stand out and are not visible in the liquid. The workpiece is left in this base for literally 20 minutes, after which the master sets the excess pressure (2-4 atmospheres). Here you need a pump or compressor unit.

- After the first part of the procedure is completed, you need to wait 30 minutes. Then everything repeats itself. If the workpiece sinks in water, it means that there are no empty pores left in it. If it pops up, a new treatment is done.

- Drying ends. Here you cannot do without heating, but special equipment is not required, you can dry the product in the oven. Temperature - 90 degrees.

If you want to make the wood more spectacular, you can add a dye (color pigment) to Anacrol-90. The process of treating wood with epoxy is similar to the previous one, but there is a significant correction for fluidity. Since the viscosity of epoxy is high, it is usually diluted with alcohol - this stabilizer works. Even so, polymerization will take time. When a vacuum is created, care must be taken not to boil the resin. If it boils, the manufacture of a new type of product may come to naught - the effect is almost unpredictable.

Little tips:

- to accelerate polymerization, the wooden workpiece must be thoroughly dried - this will remove excess moisture from it, and it will be easier for open pores to absorb the impregnating composition;

- it makes sense to filter the polymerization solution, because if there is small debris in it, it will also appear on the finished product - ordinary multilayer gauze is suitable for filtration;

- coloring in the stabilization process is not uncommon, pigments can be added to the composition, which will be interesting and unusually distributed over the tree.

The finished result is actually marbled wood, as if varnished. The best qualities of the material are preserved, but the new ones become a good bonus to the external transformation of the product. You need to follow the instructions, watch master classes if you have any questions, and not try to simplify the process in order to save time. For example, brushing on the stabilizer will not work well: it will not penetrate the pores the way you want it. Still, the best learning is from mistakes - if they are strangers.

You can learn how to stabilize small pieces of wood at home in the video below.

The comment was sent successfully.