How much does a cube of natural moisture wood weigh?

Lumber and firewood of natural moisture is in great demand due to its affordable price. In this article, we will look at how to calculate their weight, and what you need to take into account.

How does weight depend on humidity?

Humidity Is the ratio of the mass of water in the wood to the mass of the wood. This percentage is always greater than zero, since water is an integral part of the tree, it is contained in it in a certain amount. The more moisture in the wood, the more it weighs. Important characteristics such as density (specific gravity) and volume also depend on moisture.

The tree has the greatest weight and volume with natural moisture. This concept can be described in two ways.

- In a narrow sense, the moisture content of freshly cut forest is from 40 to 110%. It is also called initial. It depends on the type of tree, growing conditions and the season when it is felled. Different parts of the tree have different initial moisture content - due to this, the logs from the butt part will be heavier than from the top. The sapwood is wetter than the kernel. As it dries, the water content in different parts of the trunk (and materials from them) levels off to the same (equilibrium) state. On average, a tree with initial moisture weighs 2-3 times more than a dry tree.

- In a broad sense, this is wood and lumber above the fiber saturation point, that is, when a balance of humidity with outdoor air is achieved, and water from the wood stops evaporating. This indicator is different for different breeds and is determined by the temperature and humidity of the environment, the level of atmospheric pressure. For convenience, use the standard indicator specified in GOST - 22%. That is, in domestic practice, all materials with a water content above this level are usually referred to as materials of natural moisture. A tree with 22% moisture content weighs 1.5-2 times less than its initial weight.

The main reason why the material of natural moisture (23-80%) is in demand for purchase is its low cost (20-50% lower than dry). Without preliminary drying, it is rarely used (mainly for the creation of rafter systems, formwork, battens, floorings), since it shrinks and is subject to deformation.

Therefore, after purchase, the raw material is dried to the desired level - in accordance with GOST, the humidity should be no more than 14-23% for external work, for internal work - 8-10%.

Two methods are used for drying.

- Atmospheric - allows to obtain wood with a moisture content of 18-22% (transport moisture), takes from several months to a year, does not require special equipment. The weight of the material during natural drying is reduced by 25-35% compared to the initial one.

- Chamber - drying is carried out in a thermal chamber (convective, vacuum, microwave) and takes several days, allowing to achieve a humidity of 8-12% (room-dry).

Room-dry wood, dried artificially, has the smallest weight compared to the initial one - its weight is 30-50% less than at the initial moisture content. When buying building materials, it is important to take into account that during drying, not only their weight changes, but also their dimensions. Moreover, the shrinkage is uneven in different directions - the wood dries out more in width than in length (shrinkage in width is sometimes up to 12%). This is due to the fact that moisture does not evaporate through the entire surface of the tree, but flows down the fibers - that is, it evaporates mainly through the end surfaces of a log or board.

Shrinkage coefficients depend on the drying method and the type of wood (they are indicated in the reference books).For example, an edged board of natural moisture with a standard section of 150x50 mm (according to GOST 8486) after drying and grinding will have a section of about 145x45 mm. Depending on how much the weight and volume of different breeds changes in comparison with the initial one, they are distinguished:

- strongly drying out - larch, birch, linden, beech;

- medium-drying - most conifers, aspen, ash;

- low-drying - alder, poplar, willow.

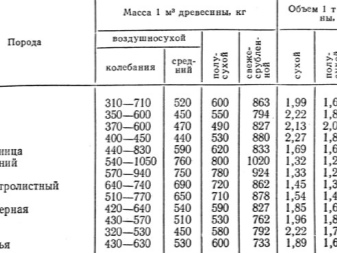

The mass of a cube of wood of various species

The main method for pre-calculating the weight of a cube of wood is tabular... The reference books give the values of the density of wood of various species (knowing which it is easy to calculate the mass) or directly the values of the mass.

For example, using the reference tables, we find out how much the initial weight of freshly cut wood differs from the weight of the material dried to 20% moisture:

- a cubic meter of pedunculate oak with initial moisture content (about 70%) weighs 990 kg, and at a moisture level of 20%, the weight decreases 1.4 times - up to 720 kg;

- a cubic meter of freshly cut fluffy birch weighs 930 kg (humidity 78%), and after drying to 20%, the weight of the material is reduced by about 30% - to 650 kg;

- the mass of a cube of spruce wood with an initial moisture content of 91% is 710 kg - this is 36% more than with a moisture content of 20% (460 kg);

- the weight of a cube of fresh larch wood is 1000 kg (humidity 82%), and air-dry (with a humidity of 20%) is 31% less - 690 kg;

- at an initial moisture content (82%), an aspen cube has a mass of 760 kg, and at 20% moisture content, the material becomes lighter by 33% (510 kg);

- a cube of freshly sawn (88% moisture) pine weighs 800 kg, when dried up to 20%, the mass decreases 1.5 times - up to 520 kg;

- when drying from an initial level (78%) to 20% humidity, the weight of a cubic meter of Manchurian ash decreases by 300 kg - from 980 kg to 680 kg;

- the mass of a cube of Siberian fir of natural moisture content (101%) is 630 kg, and with a moisture content of 20%, 1.6 times less - 390 kg;

- the weight of a cube of linden wood with a decrease in humidity from the initial (60%) to an air-dry level decreases by 23% - from 660 kg to 510 kg;

- a cubic meter of fresh beech wood (64% moisture) weighs 910 kg, and at 20% moisture - 24% less (690 kg);

- a cubic meter of freshly sawn alder (84% moisture content) after drying becomes 1.5 times lighter - from 810 kg to 540 kg.

The data presented clearly show that the difference in the weight of freshly cut wood and air-dry wood is significant - by about 30% or 1.5 times. When working with reference books, it is important to take into account that the values are given for a dense cube (if the entire volume of m3 were evenly filled with material without gaps). But in fact, even with the tightest laying, there are gaps between the boards or logs. Therefore, the actual weight of the folding cube may differ from the tabulated weight, and the difference is the more significant, the more the geometry of the material differs from straight lines.

Therefore, for an accurate calculation, it is necessary to take into account not only the wood species, but also the type of material, depending on which its own correction factors and calculation methods may be required.

Calculation features

Consider the features of the calculation for the most popular types of materials. To calculate the weight of rectangular or square sawn timber (edged, profiled, planed boards, beams), the formula is used: volume * density, where the volume is calculated by the formula length * width * height. In this way, the weight of one board is calculated, then multiplied by the number of boards in a cubic meter. For example, let's calculate how much a freshly sawn pine board 50x150x6000 mm will weigh at a humidity of 40% (the density of pine at a given humidity is taken from the reference book - 590 kg / m3).

- (6 m * 0.05 m * 0.15 m) * 590 kg / m3 = 26.6 kg - the weight of one board.

- 26.6 x 22 = 585.2 kg - cubic meter weight.

For comparison, at 20% humidity:

- (6 m * 0.05 m * 0.15 m) * 520 kg / m3 = 23.4 kg - the weight of one board;

- 23.4 x 22 = 514.8 kg - cubic meter weight.

Using this algorithm, it is easy to calculate the weight of a cubic meter of a board or timber of the required dimensions - 50x200x6000 mm, 40x150x6000 mm, 50x100x6000 mm, 150x50x6000 mm, 50x50x6000 mm and others.

An unedged board cannot be stacked as tightly as a rectangular board, and materials in a batch may vary in size. In order to calculate the weight of a cube of these materials, you need:

- selectively measure the dimensions of materials in a batch;

- calculate the arithmetic mean volume of a log or board;

- calculate the weight of one board;

- multiply the average weight by the number of boards in the batch.

If the batch is too large, and it is not possible to count the number of boards or logs, use the batch method for determining the weight - determine the volume of the package in which the sawn timber is placed, then use decreasing coefficients to calculate the weight (specified in OST 13-24-86).

To calculate the weight of a cube of firewood, the batch method is also used, but it must be borne in mind that the rules for stacking them are strictly standardized. If the firewood is stacked in bulk, in the calculations you need:

- convert the volume of the bulk cube to the fold;

- calculate the weight using the reduction factor from GOST 3243-88.

For example, to convert the volume of chopped hardwood firewood 25 cm long into a foldable cube, a factor of 0.7 is usually applied. If, for example, they are poured into a standard ZIL-130 body with low sides, then in order to find out the volume, you need to multiply the body volume of 5.98 m3 by this coefficient. The resulting value is 4.1 m3 - the volume of firewood neatly stacked in a woodpile. The weight of such birch firewood at 40% humidity is 2274.6 kg (4.1 m3 x 730 kg / m3 x 0.76), where 0.76 is a correction factor), and the weight of a cubic meter is 554.8 kg.

For round sawn timber, the calculation rules are determined by GOST 2292-88 and GOST 2708-75.

- To calculate the volume of one rounded log, use the cubic meter GOST 2708-75.

- For untreated logs, the dimensions of a certain number from the batch are selectively measured, determining the diameter along the upper (thin) edge, excluding the bark. Further calculations are made on the basis of the averaged indicator.

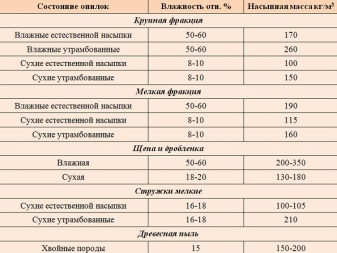

To calculate the weight of bulk materials (sawdust, shavings), use the correction factors from the appropriate lookup tables.

The comment was sent successfully.