All about the properties of wood

Knowing everything about the properties of wood, and not just about what it is in terms of hardness, is useful for general development, and for the direct organization of various industries. It is imperative to pay attention to the technological properties and humidity. But it is also worthwhile to imagine in advance what useful properties wood has.

Physical properties overview

Colour

The color of wood largely depends on the degree of its saturation with tannins. Therefore, it is clearly tied to the climatic and soil characteristics of various localities. The main rule is simple: the greater the solubility of mineral salts, the darker the material will turn out. But what color a particular tree has depends also on:

- intake of mineral salts;

- processing features in production;

- degree of humidity;

- lighting characteristics;

- burnout over time;

- fungal lesions.

Shine

Physically, this parameter expresses the degree of directional rejection of the luminous flux. The smoother the surface of a particular sample, the higher it is... It is not for nothing that properly polished boards and panels, almost regardless of the original breed, shine especially strongly. But still, the features of the breed always leave an imprint on the nature of such shine.

And again, it is necessary to take into account the unequal manifestation of such a parameter at different illumination levels.

Texture

In many ways, it is this property that is considered determining the appearance of the wood in the end. Texture refers to a specific pattern. It is usually found not on the surface, but on the cut. The texture is influenced by:

- already mentioned color;

- features of fibers and their location;

- tree rings;

- pigments inside.

Smell

The specific aroma is perhaps the most pleasant property that wood has. The strongest smell is characteristic of the kernel, because there is the highest concentration of aromatic substances. A newly felled tree smells stronger, then fainter. After some time, it is almost impossible to catch this smell. It is most attractive for such specimens:

- juniper;

- lemon tree;

- cypress;

- teak;

- peach;

- yellow wood.

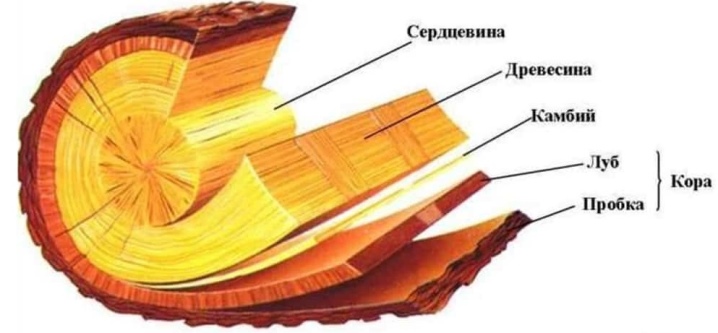

Macrostructure

This is the name of the structure of a tree, detected either when viewed with the naked eye, or with a slight increase, for example, with a magnifying glass. You can notice the macrostructure on any cuts of the trunks. The core, cambium and the wood itself are all parts of the macrostructure.

This also includes the growth rings, which make it possible to judge the age of the tree, in what conditions it grew and developed.

Humidity

This indicator usually passes as negative because the smaller it is, the easier it is to work with wood, the more predictable its other parameters and the more reliable the finished product. Freshly cut wood has a fairly high degree of moisture. Under normal conditions - a temperature of 20 degrees - a tree can absorb up to 30% of water in absolute terms from the external environment. It cannot naturally exceed this indicator, unless there are some special circumstances that increase the saturation with liquid up to 50 or even up to 100%. Remarkably, it hardly depends on the breed and even on the region of origin.

The standard according to GOST is simple: if the water content is below 22%, then this is dry lumber, and at a higher concentration, it is classified as a wet category. However, for practical purposes, it is, of course, impossible to limit ourselves to such a standard level. In addition, it must be remembered that according to GOST, the water content in class 4 wood is not standardized. The definition of this indicator is made in various ways. For professional purposes, it is measured using a special device - an electric moisture meter.

However, experienced joiners and carpenters can determine moisture content by eye with a fairly high accuracy. Of course, this is not enough to draw up documentation on the quality of the batch, but it is enough for the selection of sawn timber for construction or furniture production.

You can also check moisture using a weight test. Usually air-dry wood is considered normal, the moisture content of which does not exceed 15-20%. Most often, to achieve this result, more or less long drying is needed.

A tree with a moisture content of more than 100 percent is considered wet. (according to the coefficient of weight addition due to dampness). But this is only possible with prolonged exposure to water. Humidity is considered normal from 30 to 80%, although, of course, they do not strive to reach the upper limit, but try to use the driest lumber as possible, ideally no more than 12%. The calculation is made according to a fairly simple formula.

The initial moisture index is determined by subtracting from the initial mass the mass that will be in an absolutely dry state, and then dividing this by the absolutely dry mass and multiplying by 100%. It must be understood that even if the surface is dry, there may still be a fair amount of moisture inside. In some cases, you can hear about the so-called equilibrium moisture content of wood. It implies such a state when the pressure from the external environment is completely balanced by the pressure from the side of the liquid contained in the pores and cells. This indicator, like other types of water saturation, directly affects the suitability of raw materials for certain practical purposes.

With increasing moisture content, lumber:

- becomes significantly wider;

- lengthens somewhat;

- in combination with an increase in temperature, it acquires plasticity;

- over a long period of time (comparable to the usual service life), it wears out and degrades faster, rots more often and more actively.

Moisture absorption

But water is not only contained initially, but also comes from the outside during the entire period of use of the products. The intensity of its absorption is precisely called moisture absorption. Some heat is generated when water is adsorbed.

But this process will gradually slow down. When approaching the saturation limit, it generally proceeds in an extremely slow manner.

Moisture conductivity

It is about passing the so-called bound water. The moisture conductivity coefficient takes into account the movement of both the liquid itself and the vapor phase. It happens through:

- cell cavities;

- intercellular spaces;

- capillary systems of cell membranes.

Shrinkage and swelling

When professionals pronounce the word shrinkage, it is devoid of any ironic connotation. This is quite a serious term, meaning the degree to which the size of the wood or product from it is reduced by removing the moisture present there. For each breed and even for a specific density level, this indicator can differ significantly. In different geometric directions, shrinkage is non-uniform. The physical meaning of swelling consists in the penetration of water molecules into the cell walls and in their moving apart cellulose fibrils, this phenomenon is mainly characteristic of overdried wood or exposed to seasonal changes in moisture content.

Internal stresses

In its natural state, any tree trunk grows in a balanced way, even if it has to develop crookedly.But when the same trunk is cut down, the wood "leads", because these tensions get out of control, lose all harmony. The most powerful of them are found immediately, as soon as the trunk is sawn. However, sometimes the problem reveals itself much later, after the boards have dried and fastened to the created structure.

Visually, this is expressed in the appearance of various cracks, the correct industrial drying turns out to be the solution to the problem, and that is why it cannot be considered that it only raises the price, as is often thought.

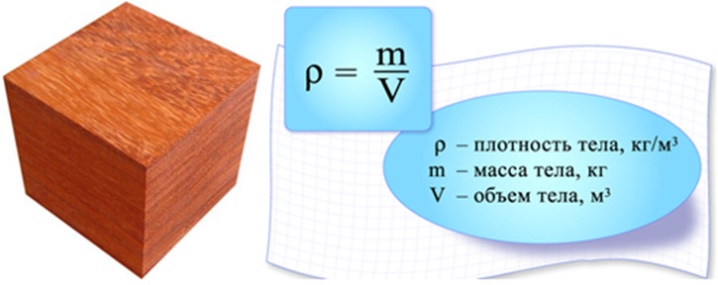

Density

This is an indicator of the mass of a certain unit of the volume of a tree. Important: it is calculated by deliberately ignoring the mass of voids and contained moisture, only the net gravity of the dry matter matters. For each breed, the density is strictly individual. This indicator is closely related to the following parameters:

- porosity;

- humidity;

- absorption rate;

- strength;

- susceptibility to biological damage (the denser the sample, the more difficult it is to damage it).

Permeability

The ability of wood to transmit liquids and gases should not be underestimated. It directly affects the development of drying and impregnation modes, and the assessment of the feasibility of such modes. Permeability to water is determined not only by the species of wood, but also by the location in the trunk and the direction of movement of liquids and gases. Permeability along the grain is significantly different from the rate of penetration across the grain. It is also worth considering the important role of resinous substances that interfere with the flow of water and other liquid substances.

Gas permeability is defined as the amount of air that has passed through. It is measured in terms of 1 cubic meter. see sample surface. This indicator is determined:

- pressure;

- the properties of the wood itself;

- properties of vapors or gases.

Thermal

It is they who are most often mentioned among the useful properties of natural material.... But in reality, the situation is somewhat more complicated than just “good heat retention”. The specific level of heat capacity is not so strongly dependent on the rock and density. It is determined primarily by the ambient temperature. The higher it is, the higher the heat capacity, the dependence is almost linear.

It is also worth paying attention to thermal diffusivity and thermal conductivity. Both of these properties are directly related to the density of the substance, because each cavity containing air plays an important role. The denser the wood, the higher its thermal conductivity. But the thermal conductivity index, on the contrary, drops sharply with an increase in the specific mass of the sample.

Cells and fibers transmit more heat in the longitudinal direction than in the transverse direction.

But sometimes wood is also used as fuel. In this case, the calorific value is critical. For a completely dry tree, it ranges from 19.7 to 21.5 MJ per 1 kg. The appearance of moisture, even in small amounts, dramatically reduces this indicator. The bark, with the exception of birch, burns at the same temperature as the wood itself.

When using wood as a fuel, the main importance is given to such a thermal property of wood as the heat of combustion (calorific value), which for absolutely dry wood is 19.7-21.5 MJ / kg. The presence of moisture greatly reduces its value. The heat of combustion of bark is approximately the same as that of wood, except for the outer layer of birch bark (36 MJ / kg).

Sound

The vast majority of builders are interested only and exclusively in the ability of wood to absorb extraneous sounds. The higher it is, the better the material will protect the house from street noise. However, in the production of musical instruments, such a property as resonance plays an important role.

Professionals are still studying the radiation constant, it is also the acoustic constant. It is according to her that the suitability of a certain breed or even a specific sample for practical use is assessed.

Electrical

It is, first of all, about electrical resistance and electrical strength... The degree of resistance to current is determined by the type and direction of the fibers. However, temperature and humidity levels are predictably important. Under the electrical strength, it is customary to understand the required electric field strength, which is sufficient for breakdown. The more the wood is warmed up, the higher its temperature, the lower the resistance to such breakdown.

Manifested when exposed to radiation

In case of infrared radiation, the surface areas of the wood can become very hot. However, a very strong impact of this kind is necessary so that the trunk of a thick tree is modified to the full depth. Curiously, the penetration of visible light occurs much deeper - by 10-15 cm. The features of light reflection make it possible to judge well the defects of the material. Ultraviolet light penetrates wood poorly.

But it provokes a specific glow - luminescence. X-rays can detect even small structural defects. It is often used for professional diagnostics. Beta radiation is used to study growing trees. Gamma rays can detect very deeply hidden defects, rot, and so on.

Description of mechanical properties

Strength

This is the name of the ability to resist destruction when a load is applied.... The degree of strength depends on the amount of bound moisture. The higher it is, the lower the resistance to mechanical stress. However, after overcoming the threshold of hygroscopicity (about 30%), this dependence disappears. Therefore, comparison of the tensile strengths of samples is allowed only with an identical degree of moisture.

The resistance is necessarily measured not only along the fibers, but also in the radial and tangential directions.

Hardness

Almost everyone knows that wood can be of different hardness, and that this is one of the main indicators when selecting it for specific purposes. Experts define hardness as the force of resistance to the introduction of foreign objects, including hardware. In addition to the list or scale for the species of coniferous and deciduous trees, there is also its classification according to the area of hardness. End hardness is established by indenting a metal rod with a certain diameter and shape of the end to a given depth of radius smoothly within 120 seconds. Estimates are made in kilograms per square centimeter.

Also distinguish radial and tangential hardness. Its indicator in the lateral plane of a hardwood board is almost 30% lower than from the end, and for a coniferous massif the difference is usually 40%. But much depends on the specific breed, on its condition and storage characteristics. In some cases, the hardness is measured according to the Brinell system. In addition, specialists always take into account how hardness can change during processing and during use.

The strongest tree in the world is:

- jatoba;

- sucupira;

- Amazonian yarra;

- turbidity;

- Walnut;

- merbau;

- ash;

- oak;

- larch.

Quality factors

But just figuring out which tree can withstand the loads the most without collapsing is far from enough. It is necessary to pay attention to other significant aspects. First of all, on the relationship between mechanical parameters and bulk density. The heavier the wood, the better its mechanics usually.... The corresponding relationship is described by a number of complex formulas. But in order to take into account certain conditions and places of growth, additional correction factors are introduced.

Weight profitability is reflected by the coefficients:

- overall quality;

- static quality;

- specific quality.

Features of technological properties

The main technical properties of wood, along with the already mentioned hardness, are:

- impact strength;

- efficiency of retention of hardware;

- bendability;

- prone to splitting;

- wear resistance.

Viscosity characterizes the absorbed work on impact, which does not lead to the destruction of the material.

The test is carried out on special samples. Pendulum copra is used for its implementation.

The pendulum in the raised state stores potential energy. After releasing in unimpeded movement, it rises to one height, and having spent part of the impulse to destroy the sample, to another height, this allows us to determine the expenditure of efforts.

Devices are usually equipped with a special scale. Having counted the readings, they are substituted into the formulas, and in this way the impact strength indicator is obtained. It must be understood that we are talking about comparing the quality of samples, and not about the calculations of wooden structures. It was found that deciduous species are more viscous than coniferous massif. As for the retention of hardware, it depends on the frictional force that occurs between the material and the fasteners inserted into it.

Additionally, the so-called pull-out resistance value is determined. In addition to density, it is also determined by the type of wood and whether the hardware enters the end or across the fiber. By wetting the wood, it will be possible to simplify the same driving of nails, but the dried material holds them worse. The resistance to bending force has to be evaluated mainly in cases where bending is technologically necessary to obtain a certain product. There is no standardized method for assessing this indicator.

Wear resistance is almost always defined as the resistance to friction. It is only in rare cases that resistance to other wear and tear influences plays an important role. It is important to understand that it is measured by the surface layer. If the destruction has reached the core, there is no point in further studying the topic - the consequences are already clear. A standard method for assessing wear resistance is provided in GOST 16483 of 1981.

The comment was sent successfully.