Natural drying of wood

Wood is used as a material for construction, decoration, furniture and decorative items. It is difficult to find an area in which this material is not involved. In this case, the wood should be dried before use. Natural drying is the simplest and most well-known for a long time, however, it has its own subtleties.

What is it for?

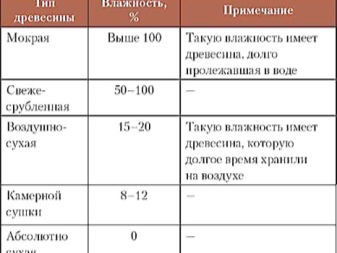

Wood is able to absorb water from the air, and therefore it is divided into types depending on the degree of humidity. Wet wood is easy to bend, but difficult to handle. Moisture options:

- wet - 100%, was in direct contact with water for a long time;

- freshly cut - 50-100%;

- air-dry - 15–20%, lay in the open air for a long time;

- room-dry - 8-12%;

- absolutely dry - 0%.

Natural drying of wood removes moisture from the material. This can reduce the size and volume of the tree. This is taken into account in the allowances for shrinkage in width and thickness. The material slightly decreases in length, so this parameter is usually neglected.

For the manufacture of furniture, the moisture content of the material is permissible in the range of 8–10%, for construction sites - 10–18%. In production, they use drier workpieces with an indicator of 1–3.5%. This is to ensure that the product does not dry out after manufacturing. Features of atmospheric drying of wood:

- prevents the formation of fungus and biological damage;

- the tree does not deform if it is dried;

- the service life of the material increases;

- suitable for any type of wood;

- takes quite a long time.

Natural drying of wood is relatively easy. Mechanisms may still be needed for stacking wood. However, a manual method is also provided.

In many ways, the choice depends on the amount of lumber. If the beams are few, it is quite easy to lay them out in the right way yourself or together with an assistant.

Advantages and disadvantages

Atmospheric drying has been used for many years. The peculiarity of the method is that it can be implemented at home without additional equipment. Main advantages:

- you will not have to spend finances on fuel and electricity;

- it is not necessary to build an additional drying room;

- the method does not imply the use of expensive equipment, which means that no skills are needed to work with it;

- no need for additional staff or labor.

The disadvantage of atmospheric drying can be considered the duration of the process. It may take a year or more to bring the tree to the desired condition. The exact time depends on material characteristics, drying conditions, season and weather. It is also important to strictly adhere to the technology.

If it is wrong to dry the wood, then it will warm up externally, but not internally.... In this case, the risk of serious deformations is too great.

You will also need a separate room for long-term storage. There should be no insects that can harm the wood.

Laying methods

Natural drying of wood requires some preparation of the material. The rest will only have to wait. The success of the entire drying depends on the way the lumber is laid. It is worth considering this issue as carefully as possible.

Usually the tree is stored in stacks. Time, uniformity and quality of drying depend on styling. You should experiment, periodically change individual elements of the stack.This will allow you to deduce the ideal option for specific conditions. Styling features:

- the size of the stack directly depends on the climatic zone;

- it should be laid on a special base, it should be quite strong, this is the only way to avoid breaking during the drying process;

- the supports of the under-head base are made in the form of portable concrete pyramids; alternatively, a wooden cage with cross-beams measuring 60x60 cm is used.

Shoulder straps from beams are laid on the supports. The maximum thickness should not exceed 10-12 cm... The stack can contain wood of the same species and size. The last boards are laid horizontally, indented, on the face or edge. They must be separated by cross shims.

The role of the latter can be played by dry wood slats 2.5x4 cm in size. If the stack is wider, the middle will dry out too slowly. This result is unacceptable. The width of the spacing should increase evenly towards the middle of the stack. So the center indents will be 3 times larger than the extreme ones.

The dimensions of the stack depend solely on several factors: the type, the method of stacking, the size of the bars. When laying by hand, the height does not exceed 4–5 m, and when using machines - 7–8 m.

It is worth considering the size of the storage area. So, it should be possible to provide protection for the end parts and equip a canopy.

Drying process technology

Natural drying is also called atmospheric. This is due to the fact that the board dries out in the open air. The process does not require any devices and technological solutions. Drying of a small amount of materials is especially successful at home in the summer.

If a ridge with bark is used as the initial raw material, then the coating is not removed. It is enough to make notches across. Along the edges, strips of bark about 10 cm thick are acceptable.

Atmospheric drying is especially important for birch, linden, aspen and other hardwoods. This approach ensures that there are no cracks.

The ends of the lumber are sometimes oiled. Alternatively, you can simply grind these parts. This provides additional protection. Requirements for the room in which drying is performed:

- dryness and good ventilation;

- obstruction to direct sunlight - they should not fall on the wood, otherwise the outer part will warm up excessively, while the inner part will remain wet, there is a high risk of cracks;

- the stack must be raised 60 cm or more from the groundit is also important to provide clearances for free air circulation.

Natural outdoor air drying is usually carried out during the warm season. In this case, the wood is kept right on the street. The stacks are placed on a substrate under the canopy. It is also important to provide artificial shading so that the sun does not burn the tree in direct rays. On the street, it is also important to make sure that precipitation flows down from the roof without getting onto the material.

Drying in a special room is more reliable. Air temperature, ventilation and humidity levels can be controlled. Further storage of the dried material in this case will also not cause problems. The wood can be dried immediately after cutting. The duration depends on the breed, the size of the bar, the conditions.

Drying times are usually quite long. This is the main negative aspect of this technique. Wood dries about 1-3 years. A moisture meter is used to measure the result. It has a fairly low cost.

Subject to technological standards, you can dry the tree to a state in which it is suitable for construction. If you plan to manufacture furniture or other products, then the drying time will increase significantly. The home technique can also come in handy in cases where the material is simply wet due to precipitation. If the tree is to be used for serious purposes, then a moisture meter is necessary.In another case, you can simply knock on the material: a ringing sound indicates dryness.

The comment was sent successfully.