Impact drills: pros and cons, choice and application

An electric drill is a useful hand tool that is powered by an electrical network. Main purpose: drilling holes in any materials. Modern drills for the most part are made universal, the drill can be used as a mixer, screwdriver, hammer drill, and so on.

What it is?

An impact drill powered by a 220 volt network can be either professional or household. The household device is not designed for long-term and productive work, they should be allowed to "rest" on average every 15-20 minutes.

When drilling various hard surfaces that are made of materials such as concrete, brick, shell rock, a hammer drill is required. If there is none, then situations often arise when it is not possible to drill concrete. The reason is simple: the cutting edge of the drill cannot capture hard fractions without first chipping. This means that the drill will simply slide over the material without causing any damage to it.

Small drills are good to use for work at home, when it is necessary to perform a small amount of drilling, it makes no sense to purchase an expensive hammer drill for this.

The device with a percussion mechanism simultaneously acts as a mini-puncher, which allows you to work with almost any material.

The drill can be two-speed with reverse or three-speed with reverse, the presence of various functionalities makes it possible to choose the best option for work.

pros

Plastic materials (wood, plastic, etc.) are "cut" with a drill. Stone, brick "give in" only with the participation of a mechanical impulse.

The advantages of an impact drill are that it is possible to work with any material.

Among the shortcomings, it should be noted: the drilling accuracy is noticeably inferior to a good drill. In shock operation, too much background noise is also observed. Household drills have low productivity.

For household work, the power of 560 W is quite enough, this is enough to drill even concrete with holes with a diameter of 15 mm. Impact Drill Benefits:

- compactness;

- little weight;

- versatility of use in a domestic environment;

- convenient functionality;

- the ability to work with a variety of materials;

- the ability to work with various drills;

- ease of use and repair;

- long service life.

Minuses

Impact drills also have a number of disadvantages:

- mechanisms are low-power, they can only cope with a limited amount of assigned tasks;

- to work with hard materials for a long time requires physical effort;

- strenuous operation of the unit when working with concrete quickly leads to its deterioration;

- the drill hits the material as hard as a hammer drill.

Views

A good drill can be used not only for drilling various holes, but also for many other jobs. Drill differentiation:

- ordinary;

- drums;

- rechargeable;

- powered by the network;

- mixers;

- corner;

- diamond works.

A professional drill is more powerful, capable of working for a long time without any complaints. Such a tool costs three times more.

It can be stated: professional drills produced by a brand manufacturer correspond to the price-quality category.

Rechargeable

A cordless drill can be very handy, for example, for plasterboard work. It does not require a lot of power, you need qualities such as:

- compactness;

- ease;

- autonomy.

The power of such devices does not exceed 410 W, you have to work at a height under the ceiling, and a good trouble-free drill can become an indispensable tool. In fact, the design of the battery device (including the impact version) is a combination of a drill and a screwdriver. Their advantages are that they are easy to use and reliable. Quick-release chucks have long been around, when bits are installed directly into the spindle. Nonetheless, cordless drills remain in favor. Drill drivers can be "armed" with a hammer drilling mechanism.

It is important to pay attention when buying, what is the battery in the drill. Nickel-cadmium batteries do not last long, they must be constantly in operation, otherwise they quickly deteriorate.

Batteries of the metal hydride group are very good, as well as lithium ion chargers. Their power is limited, does not exceed 36 W, so the work of such a drill can be effective for several hours.

Network

Choosing a corded drill, three important criteria should be followed.

- Engine power. The higher this indicator, the more work you can handle in a short period of time. But power drills, powered by the mains, are often cumbersome, so this factor should also be taken into account.

- Rotation ratio drill depends on the power of the device, the higher the ratio, the greater the performance of the drill.

- Torque also very important, this figure shows how easily the resistance is overcome during the rotation of the spindle.

But it should also be borne in mind that power drills, where there is a detachable power cord, have proven themselves best in the work. It is convenient to work with it, its optimal length is four meters.

Rating

One of the best powerful impact drills is considered Metabo SBE900 Impuls.

Every year Metabo's electric tool becomes the leader of the marketing charts, overtaking such giants as Bosch and Makita. The cost of such a power tool is quite high. The price, for example, for one of the best SBE900 drills, with all the desire to budget, can not be called by any means.

The engine of this device has a power of 900 W; drills of medium diameters can be used.

The tool weighs only about three kilograms, has well-thought-out functionality, and is easy to use. The vibrations transmitted to the hand are relatively small. The oscillation frequency can reach several tens of thousands per minute.

The drill has a convenient mechanism that can adjust the rotation speed, its advantage is that it makes it possible to select the optimal torque mode. In order to set the desired mode, there is a tuning wheel located on the front of the case.

The drill body is made of aluminum, it contains a gearbox that activates a switch.

The functionality is largely copied from the models of the best rotary hammers. A clutch is “hidden” inside the body, which reliably protects the mechanism in case the drill unexpectedly jams. Metabo is not cheap, but it is trouble-free and has good power.

If we talk about the shortcomings of this impact drill, then it should be said about the cartridge. He does not cope well with drills of large diameter, they slip. A quick-release mechanism is not needed in this design. The best option would be to use a traditional chuck, which is adjustable with a key.

Metabo prices vary as follows:

- Metabo SBE900 Impuls about 20,000 rubles;

- Metabo SBE 701 SP - 15,000 rubles;

- Metabo SBE 760 about 7,000 rubles.

Makita HP1640K costs three times cheaper than the Metabo SBE 900, so it makes sense to take a close look at this good tool.Ergonomics and functionality are thought out to the smallest detail, drilling with a drill is easy and pleasant. For homework, a similar tool is quite suitable. The power is 685W, and the speed can be effectively controlled. The unit weighs two kilograms, which allows you to work with one hand. Among the shortcomings, it should be mentioned: the impact mechanism is weak, but it is possible to work on concrete.

Consider the Zubr ZDU-850 ERMM2 drill. The gearbox housing is made of metal, which in itself can draw close attention. The machine is quite powerful and can function for a long time, 860 W is enough to work within a private household.

Without exaggeration, one can say: Zubr ZDU-850 is not inferior to world analogues from Makita or Bosch. The Zubr can work quite hard, it has a good margin of safety.

Of the design flaws, it should be said about the trigger on the handle - this is not the best idea to control the revs. Reason: it is difficult to smoothly accelerate the drill, at low speeds it is almost impossible to do this.

The drill starts working right off the bat, which is sometimes extremely inconvenient.

Another important drawback of the Zubr is that it lacks a strength factor for the ratchet of the percussion mechanism.

The main advantages of the device:

- good powerful engine;

- minimal vibration;

- duration and reliability in work.

How to choose?

Electric impact drills are a complex complex unit. The choice depends on a number of factors. Before buying, you should consider what the main work will be done by the tool. If you need a drill like a screwdriver for installing drywall, that's one thing. If you need an apparatus for drilling holes in brick or concrete walls, you will need a more powerful tool.

Often, a drill is used as a mixer in putty work, so the best drill is the one that allows you to implement the tasks as fully as possible in a short time. We can say with confidence: there is no point in buying cheap devices. There will be no cost savings.

When choosing, you should consider: how often you will have to use this tool. In fact, this criterion is the most important. If the volume of work is significant, it must be performed every day, then it is better to opt for a professional tool.

Buy a unit better than well-known manufacturers, they give a guarantee and know how to do good, reliable things. It is best to buy a drill in a company store, this is also an additional guarantee that the thing will last a long time. In extreme cases, it can simply be replaced.

The main criteria when choosing a hammer drill:

- engine power;

- how fast the cartridge rotates;

- what size the hole can be;

- who is the manufacturer;

- what guarantees exist;

- price;

- what functionality, how convenient it is.

Principle of operation and scope

The difference between a hammer drill for a home and a professional hammer drill is that the latter has a special drive, which is made so as to “hammer” the material, chopping off small fractions. This is done using a special bearing, which makes it possible to accelerate the impact firing pin with a high vibration frequency. Impact drills are arranged somewhat differently, their drive is made in such a way that an end ratchet is used, which pushes the chuck spindle, while the amplitude of its movement is small. It is now clear how these two instruments fundamentally differ.

The hammer in the hammer drill will acquire a large kinetic energy and work a lot due to the presence of large inertia.

In order to successfully complete tasks with a hammer drill, some mechanical effort must be applied. Eventually, the ratchet teeth wear off over time, the amplitude also decreases, and as a result, the hammer drill becomes a normal drill. Vibrations from the ratchet are transmitted not only to the working drill, but also to the hands of the master in accordance with Newton's third law.

Based on this information, it should be borne in mind: an impact drill is needed in the household, but its purpose is primarily for drilling holes. Its percussion function is an optional and necessary application.

How to get a drill repaired?

There can be several main reasons for a drill malfunction:

- the movable block of the electric engine (stator, armature) breaks down;

- bearings fail;

- the regulating button breaks;

- the reversible regulator fails;

- collector brushes burn out;

- violation of contacts, cable break;

- failure of the chuck.

Most often, to establish the cause, the unit must be disassembled. The simplest malfunction is the chafing of the cord due to intensive use of the device.

A second common malfunction may be a contact failure in the switch block.

Chuck breakage is the third most frequent defect. Drill repair is as follows: screws are unscrewed, the case is disassembled, contacts are checked, places of possible burnouts or breaks. It is not difficult to determine by the damaged insulation.

If the switch block is faulty, it is best to install a new one. It is not recommended to dismantle it on your own, there are too many small parts.

The brushes are usually changed without dismantling the case, most often it is enough for models to unscrew the plugs and put in new brushes. The first sign of problems with these parts is noticeable arcing and motor interruptions. This is caused by the violation of electrical contacts between the brushes themselves and the collector.

As a preventive measure, it is recommended to clean the collector from carbon deposits and test how tightly the brushes are on the drum.

And also a common breakdown can be the lack of engine operation. In the workshop or on your own, you can "ring" the contacts with a multimeter using the resistance mode.

The principle of troubleshooting an electric drill is based on the availability of many parts.

Sometimes it is enough to simply lubricate the moving parts.

And also the breakdown of the armature itself is often found, this often happens due to the failure of the winding. A similar phenomenon is observed in budget models, world-famous manufacturers make windings with double and triple insurance, it rarely fails. If the winding begins to melt or burn, then a characteristic odor appears, the engine power is sharply reduced.

Malfunctions are also common - this is a failure of bearings, this can be determined by their characteristic grinding, deceleration of the torque.

Reviews

In reviews on the Web, they often talk about various manufacturers. The most popular of them Metabo company, which is distinguished by excellent build quality and fit of all working units. Sometimes there are complaints about the chuck, after a certain period of work they fail, it is easier and safer to use the classic chuck, which fixes the drill "without beating".

Praise drills from Japanese manufacturer Makita, they work flawlessly, interact well with almost any material. The drill can generate very high revs and penetrate hard surfaces with extraordinary ease.

Drill "Caliber Master DE-750" is also popular, the unit has good material permeability, convenient functionality, and is not inferior in reliability to Bosch.

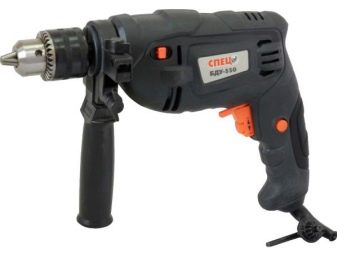

Russian impact drill "SPETS-BDU (550 - 1493)" has the perfect combination of price and quality. According to reviews, it is great for work in private households.

Hammer drill Ryobi RPD2 has a lot of power, functions flawlessly and can carry out decent volumes.

Speak well about drills "Zubr", there is also a harmonious combination of price and quality, our domestic manufacturer can make tools at the level of world standards

Hammer drill DWT SBM has established itself from the best side, it is distinguished by convenient functionality and high reliability.

And also an extremely reliable drill Iskra ERO SRE4, Ideal for housework, as evidenced by the reviews of the craftsmen.

Bosch models differ in power and compactness in size. And most of the impact drills from this manufacturer also have a tool with convenient functionality. There is a reverse and various speeds.

For information on how to choose a hammer drill, see the next video.

The comment was sent successfully.