Choosing a drill bit for sharpening drills

With frequent use of drills, it becomes necessary to sharpen them. The modern market provides various devices for this task. However, few people know that with an ordinary electric drill today, you can sharpen a drill. This is obtained thanks to all kinds of attachments and attachments, which make it possible to create a multi-purpose device from a drilling machine.

One of such devices is a nozzle for an electric drill for sharpening drills, which, in the absence of emery and a grinding stone, makes it possible to correct the shape of the drill and restore its functional properties.

Distinctive features of the design and principle of operation

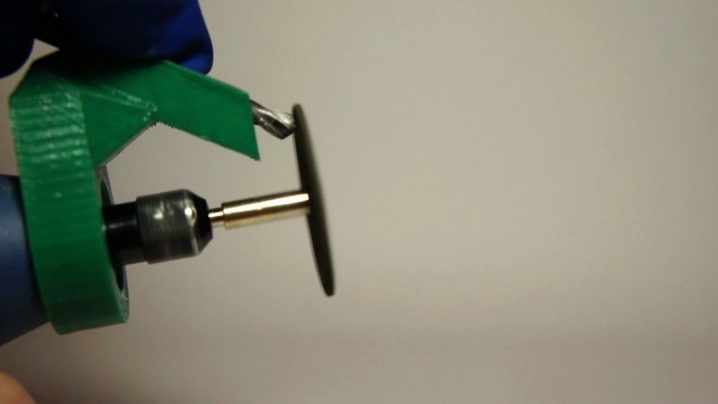

The structure of nozzles for electric drills, specializing in sharpening drills, has a plastic shell, inside of which there is a rotating sharpening wheel. This is a surface of a specialized shape that creates the necessary sharpening angles on the working elements of cutting tools.

The grinding stone of the nozzle is driven by the rotation of the shaft of an electric drill, with which it is united by a specialized coupling.

Most of the newest examples of electric drill bits for sharpening tools are equipped with an end cap on the casing, on which there are holes. The diameter of each of them is proportional to the specific size of the drill.

These holes are made in such a way that the drill, the working area of which is placed in them for sharpening, will contact the working plane of the grinding stone exclusively in a certain position.

Drill sharpening, carried out using a similar nozzle, occurs in the following way:

- The drill, the cutting area of which is to be tucked in, is inserted into a hole in the bit housing that has a suitable diameter.

- The electric drill starts up, as a result of this, the sharpening stone begins to rotate. One side of the working surface of the drill is sharpened.

- The drill is rotated 180 degrees in the hole of the nozzle, and the other cutting edge is sharpened.

The operation described above is performed several times, until the working part of the drill is brought to the required characteristics.

There are also simpler options - without the end cap. They are more primitive than a conventional device, but they are extremely uncomfortable to use. Care must be taken to ensure that the sharpening surface and the cutting edge of the drill are correctly positioned.

Such a sharpener for drills for an electric drill can also have a much more unpretentious design, where neither the presence of a cover nor technological holes, which are a jig, are provided. Practicing such bits is very difficult, they are uncomfortable for the reason that you need to hold the sharpened drill in the correct position. In addition, proper angles must be maintained on the cutting edge.

Positive points and disadvantages of using

Giving an assessment of the rationality of such attachments for an electric drill for sharpening drills, it must be noted that they are not at all intended for frequent and active use.

Some of their positive aspects include:

- Low price of products. This is due to the simple design of the device.

- Ease of use. It is quite easy to use the device, even a beginner can cope with it. In contrast to an emery machine, sharpening with a specialized bit is not only easy, but also very fast.

- Possibility of using the device for various drill diameters. A very important factor that makes it possible to sharpen large quantities of parts from a home collection with a single bit.

The described device has the following negative points:

- Inability to produce full-scale sharpening... Although the manufacturer says that the device is intended for sharpening parts, in fact, the bit is specialized, most likely, for straightening the cutting edge of a hooked drill.

- Unreliable fixation of the device to the chuck electric drills. The overwhelming majority of manufacturers produce nozzles with a plastic stopper, which is done in order to reduce the cost of the product.

- Inability to change the sharpening angle... The degree of sharpening is already included in the design in advance.

- Problems in use... In order to use the attachment, it is required to fix the electric drill in a static position, which will make it possible to comfortably use the device. At the same time, it is required to hold the electric drill with one hand, connect and disconnect it, and with the other hand manipulate the drill, directing it into the holes in the cover of the device.

Nevertheless, despite the imperfection, the device found its own user. Due to its compact size, low weight and relatively low cost, the nozzle is well realized.

They practice it in the household, in the "field" conditions, in not very large workshops.

Apart from the particulars, the analyzed devices are considered to be quite effective if practiced directly for their intended purpose.

How to choose wisely. Areas of use

The average price of sharpening equipment is no more than 1,000 rubles. Before purchasing, you need to find out the correspondence of the purchased device to the electric drill for which it is being selected.

In any case, you need to measure the bore diameter in advance, but it is preferable to check it directly on the tool.

The store will certainly have a brand of electric drill similar to yours. Back-up emery stones are included with certain attachment modifications. This is practical and will extend the life of the attachment.

Using the device, you must not forget that it is not professional equipment for sharpening... From the outset, this assembly device is not designed for heavy loads.

The interest in such adaptations is not a coincidence. High-quality sharpening from specialists on professional equipment is very expensive, and the presence of similar applications to an electric drill in the house, which almost everyone has, guarantees the perfect condition of all cutting edges and surfaces.

As mentioned above, it is necessary to select the nozzle in proportion to the modification of the electric drill. You need to pay attention to devices from well-known companies. Most manufacturers of power tools produce accessories that are perfect not only for their own products, but also for electric drills from other companies.

The best option is if the attachment is included with the electric drill itself... Before purchasing, you need to decide on the type of sharpening you need and the diameters of the drills, which in most cases are used to ensure that the operation of the nozzle is extremely effective.

Parts for picking, spare parts

The ideal option for purchasing is a nozzle with backup emery wheels.If possible, it is necessary to buy a holder for fixing an electric drill - this will greatly simplify the problem, especially if sharpening will be performed quite often.

Each device comes with a manual to help you master the new tool option. Ordinary emery stone is intended for several dozen working cycles, therefore, it is possible to calculate the intended load and acquire parts in a systematic manner.

Reviews

The views of the owners differed on the extent to which the use of the sharpening bit is effective. Effectiveness is evaluated in very different ways. Some people find the adaptation too weak to be practiced constantly. According to others, the nozzle is simply irreplaceable in specific circumstances.

Based on the reviews, we can conclude that if you do not present too large requests to the adaptation, it will turn out to be very effective.

Summarize

An electric drill attachment for sharpening drills is a rather necessary purchase when you often use drilling equipment. With its help, you can seriously save on the services of service companies.... It is only necessary to measure the potentials of this product, so as not to overload it too much, so that it does not become unusable.

Of course, an electric drill, even with such a device, is not capable of replacing one hundred percent of an emery machine, nevertheless, if you need to sharpen a drill at home, it will provide such an opportunity without any problems.

For information on how to use the drill bit for sharpening drills, see the following video.

The comment was sent successfully.