Mini drills: characteristics, features of choice and application

A mini drill is a versatile tool with a wide range of applications that performs the functions of an electric drill, grinder and milling machine, only in much smaller volumes. This compact equipment, thanks to its various types of equipment, has great functionality.

It is used in everyday life and craft activities, hand made home art, interior decoration and home decoration. Mini drills are indispensable when performing high-precision manipulations for processing a variety of materials and performing work operations in places where access with a large power tool is limited or impossible.

What is this device, what are its functions and key selection criteria, taking into account the purposes of application - the answers to all these questions are in our article.

Principle of operation and features

A mini drill is a compact and lightweight (weighing up to 1 kg) modified version of an electric drill, also called an engraver or dremel (after the name of the Dremel brand - the developer of this tool). The device is equipped with a light body, under which there are an asynchronous multi-turn motor with / without a gearbox and a spindle with a collet chuck.

A collet of different diameters is attached to the shaft of the electric motor to fix the nozzles or supplemented with a flexible shaft to transfer rotation to the working tip when it is planned to perform work of particular complexity.

According to the principle of operation, a mini-drill is similar to a conventional drill, screwdriver or grinder. The main differences between them are in the internal structure and performance.

A feature of the dremel is its high rotation speed (up to 40,000 rpm) with low power (up to 170 W). The basis of the mini-drill is a straight grinder - equipment that is used to clean and grind hard-to-reach places at the final stage of pre-finishing. However, compared to a straight grinder, it has a higher rotation speed: 5000–35000 rpm. against 2800-11000 rpm.

Scope of application and possibilities

Mini drills are used in many types of production activities:

- Jewelry Art;

- engraving;

- watch making;

- small sculpture;

- artistic cutting (wood, bone);

- glass processing;

- computer modding;

- restoration of old cars;

- aircraft modeling;

- instrument and mechanical engineering.

These compact devices have found application in various types of handicrafts associated with the creation of relief or volumetric images on products made of metal, glass, ceramics or wood.

What you can do with a dremel:

- drill holes with diameters of different sizes in wood, plastic, metal, precious materials, ceramics, glass;

- form miniature tongue-and-groove joints;

- cut in a straight line, grind, polish the listed materials and perform their milling;

- engrave on products;

- clean surfaces from oxides, rust;

- finish machining parts in two-stroke internal combustion engines in order to obtain accurate dimensions and achieve low surface roughness;

- sharpen miniature workpieces, apply patterns, drawings and inscriptions.

The fulfillment of all these functions is made possible by equipping the device with drills, milling cutters, sanding sheets, cutting discs, brushes, attachments for working with various materials.

Classification and types

There are three types of mini drills, depending on the power source and design.

- Standard electrical appliances powered by the mains... An ordinary network mini-drill has a distant external resemblance to a thick, large ballpoint pen, the end of which is equipped with a rotating working attachment. Such a device, due to its small size and ergonomic shape, is convenient to take with one hand. Electrical equipment is often equipped with a flexible shaft (sleeve), which serves as an extension, which is attached to the main collet. The tip of the sleeve is equipped with a clamping chuck, which simplifies the work with the dremel. The device itself can be conveniently placed on the table, and with your hand you can hold one end of the bending nozzle.

The presence of the shaft allows you to achieve the necessary maneuverability when processing the thinnest workpieces and get a high-quality result, regardless of the complexity of the working conditions.

- Battery powered mobile devices... Although the cost of cordless mini drills is higher than networked models, there is no fundamental difference between the two. The only difference between devices with a battery is that they have their own power source, which makes it possible to use them without being tied to an electrical outlet. Such equipment is completed with a conventional charger and an adapter for connecting to the car cigarette lighter socket.

- Suspended devices... Suspended models are equipped with a short square or cylindrical body that can be brought to a table or wall. The same sleeve extends from the body part as in standard electric engravers. Suspended devices are supplied with a foot pedal, after pressing on which the power is transferred to the electric motor rotating the working tip inserted into the collet on the spindle. The advantage of hanging mini-drills is the high-quality performance of the flexible shaft, which is very light and easy to grip by hand.

How to choose?

Today's electrical appliance market is replete with all kinds of mini-drills, which creates certain difficulties when choosing the right tool. There are a few things to look out for when buying a doorman in order to avoid mistakes and disappointments.

- Rated power Is a criterion that determines the performance of a tool. When choosing equipment of optimal power, it is necessary to take into account the purpose of its use. When it comes to home use, it is better to give preference to models with power ratings up to 200 W, and units from 240 W are suitable for professionals.

- Maximum working speed... The comfort of work is provided by units with a rotation speed of 20,000 rpm. Although against the background of branded models with a capacity of 150–160 W, capable of delivering 30,000–35,000 rpm, this value seems more than modest. For the simplest engravers for amateur purposes, the number of revolutions varies in the range of 6,000–10,000 rpm.

- Rotation speed control... The presence of a speed regulator increases the ease of use of the tool. Most mini-drills have a stepless speed control, which makes it possible to adjust the speed of the electric motor from a safe minimum to maximum.

- Weight and ergonomics... Manual units should not be heavy, otherwise the hand will quickly get tired, which can negatively affect the quality of work. It is optimal when the tools weigh 600–800 grams. and at the same time have high power.

- Noise characteristics... If in repair shops the noise level of the engraver is not so important, then for use in residential premises, low-noise equipment is definitely needed so as not to displease neighbors.

- Collet working diameter... It is the parameters of the collet that determine the possibility of installing certain nozzles into the tool. The most common collet options are Ø 2.4 and Ø 3.2 mm. They are equally suitable for home use, hobby use, and professional handling.

- Equipment... The cheapest mini drills are sold without accessories. Choosing products of a more expensive price segment, you can become the owner of an extended basic set, consisting of a flexible shaft, an angle adapter, a box with accessories, spare graphite brushes for the motor, collets with different diameters, letter templates for engraving work, a suspension stand and a case.

- Manufacturer and cost... Now there are many reputable manufacturers of high-quality and reliable power tools, among them - Boshe, Dremel, Einhell, Elitech, Hammer, Patriot, Sturm, Whirlwind, Diold, Zubr, Caliber. The prices for equipment of different brands differ - and quite significantly. When the plans include the use of an engraver from time to time, then there is no point in overpaying for expensive professional equipment from a renowned manufacturer.

Only suspiciously cheap engravers of unknown "origin", which are not accompanied by a guarantee, are subject to doubt.

How to do it yourself?

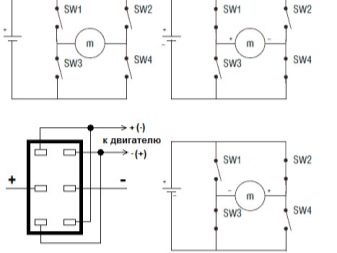

The simplicity of the design of the mini-drill makes it available to assemble it with your own hands from ready-made assemblies and components for electrical appliances.

For work you will need:

- 12V electric motor from an old radio tape recorder or a dynamic toy;

- power supply unit (PSU) 12V, you can use an adjustable PSU from 5 to 25V;

- a piece of plastic tube of a suitable diameter;

- high temperature glue;

- on / off switch;

- wires for wiring.

Procedure:

- with a knife we make a cutout for the switch in the tube;

- we process the engine with an adhesive for reliable fixation in the case and place it inside it;

- we put the positive wire from the engine into the cutout of the case, pull the negative wire out through its rear part;

- we take a soldering iron and solder both wires to the switch, observing the polarity and mandatory isolation of the contacts;

- the wires from the switch and the engine, which remained at the end of the case, are connected to the socket for the power supply unit;

- cut off the neck from the PET bottle;

- make a hole in the center of the lid for a connector, and then fix it in the hole with hot melt glue;

- we connect the assembled device to the power supply unit;

- press the button to test the performance of the homemade doze.

Such a device is convenient for drilling soft materials (wood, plastic) and engraving on wood products. It can also be useful for radio amateurs for drilling and cutting printed circuit boards.

If you equip the mini-drill with batteries, then it can work in autonomous mode.

For an overview of the Whirlwind mini-drill, see the next video.

The comment was sent successfully.