How many boards are in 1 cube?

The number of boards in a cube is a parameter taken into account by the suppliers of sawn timber. Distributors need this to optimize the delivery service, which is in every building market.

What should be considered when calculating the volume?

When it comes to how much a particular tree species weighs in a cubic meter, for example, a grooved board, then not only the density of the same larch or pine and the degree of drying of the wood are taken into account. It is equally important to calculate how many boards are in a cubic meter of the same tree - the consumer prefers to know in advance what he will face. It is not enough to order and pay for a consignment of wood - the customer will be interested to find out how many people need to be involved in unloading the boards, how long this process will take, and how the client himself organizes the temporary storage of the ordered timber before it goes into the upcoming business.

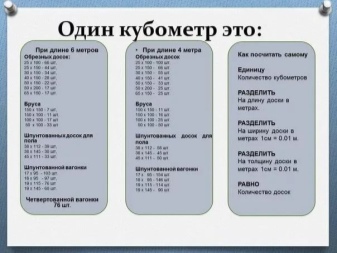

To determine the number of boards in a cubic meter, a simple formula is used, known from the elementary grades of school - the "cube" is divided by the volume of space occupied by one board. And to calculate the volume of the board, its length is multiplied by the sectional area - the product of thickness and width.

But if the calculation with an edged board is simple and clear, then an unedged board makes some adjustments. Unedged board is an element, the sidewalls of which were not aligned in length on the sawmill when preparing this type of product. It can be laid a little outside the box due to the differences in width - including the "jack" - different sides. Since the trunk of a pine, larch or other tree-like variety, loose on planks, has a variable thickness from the root zone to the top, its average value in width is taken as the basis for recalculation. Unedged board and slab (surface layer having one rounded side along the entire length) are sorted into separate batches. Since the length and thickness of the unedged board are the same, and the width varies significantly, the uncut uncut products are also pre-sorted into different thicknesses, because the strip passing through the center of the core will be much wider than the analogous part that did not affect this core at all.

For an extremely accurate calculation of the number of unedged boards, the following method is used:

-

if at the end the width of the board was 20 cm, and at the beginning (at the base) - 24, then the average value is chosen equal to 22;

-

boards similar in width are laid out in such a way that the change in width does not exceed 10 cm;

-

the length of the boards should converge one to one;

-

using a tape measure or "square" ruler, measure the height of the entire stack of boards;

-

the width of the boards is measured in the middle;

-

the result is multiplied by something in between the correction values from 0.07 to 0.09.

The coefficient values determine the air gap left by the uneven width of the boards.

How to calculate the cubic capacity of a board?

So, in the product catalog of a separate store, it is indicated, for example, that a 40x100x6000 edged board is on sale. These values - in millimeters - are converted into meters: 0.04x0.1x6. The conversion of millimeters to meters according to the following formula after calculations will also help to calculate correctly: in a meter - 1000 mm, in a square meter there is already 1,000,000 mm2, and in a cubic meter - a billion cubic millimeters. Multiplying these values, we get 0.024 m3. Dividing a cubic meter by this value, we get 41 whole planks, without cutting the 42nd. It is advisable to order a little more than a cubic meter - and the extra board will come in handy, and the seller does not need to cut the latter into pieces, and then look for a buyer for this scrap. With the 42nd board, in this case, the volume will be a little more than a cubic meter - 1008 dm3 or 1.008 m3.

The cubic capacity of the board is calculated in an indirect way. For example, the same customer reported an order volume of one hundred boards. As a result, 100 pcs. 40x100x6000 are equal to 2.4 m3. Some clients follow this path - the board is used mainly for flooring, ceiling and attic floors, for the construction of rafters and roof sheathing, which means that it is easier to purchase its calculated amount per piece - in a certain amount - than to count by cubic meters of wood.

The cubic capacity of a tree is obtained as if "by itself" with an accurate calculation to order without unnecessary overpayments.

How many square meters are in a cube?

After completing the main stages of construction, they move on to interior decoration. It is equally important to find out how many square meters of coverage will go to one cubic meter for edged and grooved boards. For cladding walls, floors and ceilings with wood, a calculation is taken of the coverage by a cubic meter of material of a specific area. The length and width of the board are multiplied by each other, then the resulting value is multiplied by their number in a cubic meter.

For example, for a board 25 x 150 x 6000, the coverage area can be measured as follows:

-

one board will cover 0.9 m2 of area;

-

a cubic meter of board will cover 40 m2.

The thickness of the board does not matter here - it will only raise the surface of the finishing finish by the same 25 mm.

Mathematical calculations are omitted here - only ready-made answers are given, the correctness of which you can check yourself.

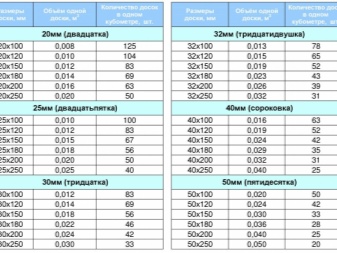

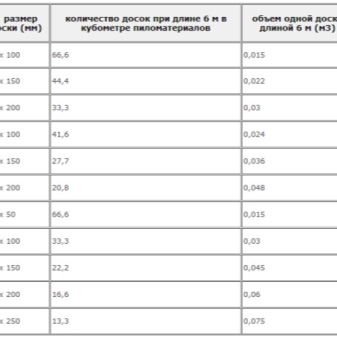

table

If you don't have a calculator at hand now, then the tabular values will help you quickly find the required rating and determine its consumption for the coverage area. They will map the number of instances of a board of a particular size per "cube" of wood. Basically, the calculation is initially based on the length of the boards of 6 meters.

It is no longer advisable to saw boards by 1 m, except for cases when the finish has already been completed, and furniture is made from the remains of wood.

|

Product dimensions, mm |

The number of elements per "cube" |

The space covered by the "cube", m2 |

|

20x100x6000 |

83 |

49,8 |

|

20x120x6000 |

69 |

49,7 |

|

20x150x6000 |

55 |

49,5 |

|

20x180x6000 |

46 |

49,7 |

|

20x200x6000 |

41 |

49,2 |

|

20x250x6000 |

33 |

49,5 |

|

25x100x6000 |

66 |

39.6 m2 |

|

25x120x6000 |

55 |

39,6 |

|

25x150x6000 |

44 |

39,6 |

|

25x180x6000 |

37 |

40 |

|

25x200x6000 |

33 |

39,6 |

|

25x250x6000 |

26 |

39 |

|

30x100x6000 |

55 |

33 |

|

30x120x6000 |

46 |

33,1 |

|

30x150x6000 |

37 |

33,3 |

|

30x180x6000 |

30 |

32,4 |

|

30x200x6000 |

27 |

32,4 |

|

30x250x6000 |

22 |

33 |

|

32x100x6000 |

52 |

31,2 |

|

32x120x6000 |

43 |

31 |

|

32x150x6000 |

34 |

30,6 |

|

32x180x6000 |

28 |

30,2 |

|

32x200x6000 |

26 |

31,2 |

|

32x250x6000 |

20 |

30 |

|

40x100x6000 |

41 |

24,6 |

|

40x120x6000 |

34 |

24,5 |

|

40x150x6000 |

27 |

24,3 |

|

40x180x6000 |

23 |

24,8 |

|

40x200x6000 |

20 |

24 |

|

40x250x6000 |

16 |

24 |

|

50x100x6000 |

33 |

19,8 |

|

50x120x6000 |

27 |

19,4 |

|

50x150x6000 |

22 |

19,8 |

|

50x180x6000 |

18 |

19,4 |

|

50x200x6000 |

16 |

19,2 |

|

50x250x6000 |

13 |

19,5 |

Boards with a footage of 4 meters are formed by sawing 1 piece of six-meter specimens at 4 and 2 m, respectively. In this case, the error will be no more than 2 mm for each workpiece due to the forced crushing of the wood layer, which coincides with the thickness of the circular saw on the sawmill.

This will happen with a single cut along a straight line passing through the point-mark, which was set during the preliminary measurement.

|

Product dimensions, mm |

The number of boards per "cube" |

Square coverage from one "cube" of products |

|

20x100x4000 |

125 |

50 |

|

20x120x4000 |

104 |

49,9 |

|

20x150x4000 |

83 |

49,8 |

|

20x180x4000 |

69 |

49,7 |

|

20x200x4000 |

62 |

49,6 |

|

20x250x4000 |

50 |

50 |

|

25x100x4000 |

100 |

40 |

|

25x120x4000 |

83 |

39,8 |

|

25x150x4000 |

66 |

39,6 |

|

25x180x4000 |

55 |

39,6 |

|

25x200x4000 |

50 |

40 |

|

25x250x4000 |

40 |

40 |

|

30x100x4000 |

83 |

33,2 |

|

30x120x4000 |

69 |

33,1 |

|

30x150x4000 |

55 |

33 |

|

30x180x4000 |

46 |

33,1 |

|

30x200x4000 |

41 |

32,8 |

|

30x250x4000 |

33 |

33 |

|

32x100x4000 |

78 |

31,2 |

|

32x120x4000 |

65 |

31,2 |

|

32x150x4000 |

52 |

31,2 |

|

32x180x4000 |

43 |

31 |

|

32x200x4000 |

39 |

31,2 |

|

32x250x4000 |

31 |

31 |

|

40x100x4000 |

62 |

24,8 |

|

40x120x4000 |

52 |

25 |

|

40x150x4000 |

41 |

24,6 |

|

40x180x4000 |

34 |

24,5 |

|

40x200x4000 |

31 |

24,8 |

|

40x250x4000 |

25 |

25 |

|

50x100x4000 |

50 |

20 |

|

50x120x4000 |

41 |

19,7 |

|

50x150x4000 |

33 |

19,8 |

|

50x180x4000 |

27 |

19,4 |

|

50x200x4000 |

25 |

20 |

|

50x250x4000 |

20 |

20 |

For example, a 100 x 30 mm board with a length of 6 m - of any thickness - will cover 0.018 m2.

Possible mistakes

Calculus errors can be as follows:

-

the wrong value of the cut of the board is taken;

-

the required length of the product copy is not taken into account;

-

not edged, but say, tongue-and-groove or not trimmed board on the sides;

-

millimeters, centimeters are not converted to meters initially, before the calculation.

All these mistakes are the result of haste and carelessness.... This is fraught with both a shortage of paid and delivered saw wood (timber), and its cost overruns and the resulting overpayment. In the second case, the user is looking for someone to sell the leftover wood, which is no longer needed - construction, decoration and furniture manufacturing are over, but there is no reconstruction and is not expected in the next, say, twenty or thirty years.

Very informative material that will be useful when building a new home.

The comment was sent successfully.