All about WPC decking

The happy owners of private houses know that behind the large footage, freedom and comfort of living in the fresh air, there is a constant work to keep the entire territory in order, including the local area. Today, more and more often, the owners of country houses decide to arrange a terrace - this part of the home is actively used not only in summer. But wood on the street seems to be a material with which there will be a lot of hassle. And then the gaze of the owner of the house turns to a special decking made of wood-polymer composite.

What it is?

Decking is a material designed for outdoor flooring. Such decking is used on the terrace, both open and covered, hence the name. They also use the board in the design of swimming pools, in gazebos and other buildings and structures that are found on the territory of a private house.

The operating conditions of the board are obviously not the most comfortable: wind, precipitation, bad weather, exposure to various biofactors put forward strict requirements for the characteristics of the board. Strong, durable, resistant material must also be attractive in appearance.

By the way, another name for decking is decking (if you translate exactly - deck flooring). Therefore, if someone calls the material a deck board, there is no confusion, all these names are valid.

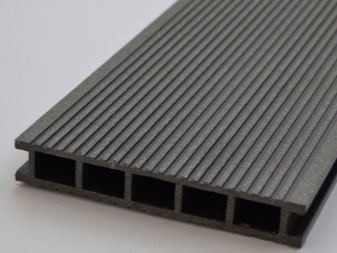

There are longitudinal grooves on the front surface of such a board - it is easy to guess that they are made for water flow. These grooves allow the flooring to be less slippery when it rains. Obviously, this is very important on the deck, but the same properties are needed for flooring, which can be flooded with rain, be covered with snow in season, etc. But not always there are grooves on the decking - now this is not a strict requirement for the board. However, many homeowners prefer to take just such a material: even outwardly, it is associated with the design of a cozy terrace.

How are WPC decking boards made?

The original decking consisted of pure wood. We used very dense types of wood, always with a strong resinous content. And they, of course, do not grow everywhere. Buying exotic raw materials would be a deliberate failure (at least on a large scale), so domestic producers needed an alternative. Larch showed good properties in terms of quality and service life. And decking is actively made from this wood, but there is one drawback - the gray color that it acquires over time.

The next solution was to use wood that had undergone a special heat treatment. The wood was kept at a temperature of about 150 degrees, due to which the density of the material increased, and the wood absorbed water much less. And if you process it properly, it also resisted the fungus without any complaints. But the price of the product was not affordable for everyone.

Then the request formed by itself - you need a reliable artificial material. Outwardly, it should be similar to a tree, but its properties should be superior to a natural product. This is how the wood-polymer composite appeared. The composition of such products includes a mixture of polymer and wood fibers, and dyes are also added to the production. Extrusion on special equipment forms boards from this mixture.

The modern buyer is picky about various PVC, plastic and polymer structures. But plastic decking is not an attempt to replace eco-material with cheap plastic and "take the buyer by the wallet."

It should be noted that a high-quality WPC decking board is not cheap. This option is a compromise: natural material is favorably combined with artificial, due to which a flooring is formed that is ready to serve for a long time, does not deteriorate the external properties and fully fulfill the requirements of outdoor flooring.

Advantages and disadvantages

Nobody argues that real wood is a material that almost does not recognize competition. And although it also has negative properties, it is a natural material, beautiful in itself, creating a unique texture. But on the same terrace, a natural board would have to be looked after so much that there would be less and less time left to admire it. There is no need to talk about the practicality of such an environmentally friendly flooring.

One has only to imagine: every year the wooden floor on the terrace needs to be renewed. At least soaking it with oil is minimal maintenance. Good oil is not cheap, and time needs to be taken into account as well. There is really a lot of trouble. From moisture, natural wood swells, and in the open sun it can dry out quite quickly. That is, as a result, such a natural and beautiful flooring may have the problem of its constant "humpback".

What does the WPC decking board offer?

- Visually, the coating is not satisfactory... And after years it retains its original appearance. Neatly, concisely, strictly.

- Durability - is also one of the promises of the manufacturers. The minimum service life of the board is 10 years. In fact, it can last all 20 or more. Of course, such guarantees are provided only by certified goods.

- Not afraid of operational difficulties. It will withstand both almost polar temperatures (up to -50) and the African heat (up to +50).

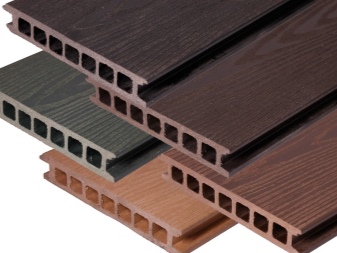

- The appearance of the board does not change for a long time. It may fade slightly over time, but these changes are minor. Decking fading depends on how much wood is in its composition. It's simple: the more natural fibers there are, the more natural its appearance, but also the faster the fading.

- The decking practically does not absorb water. That is, you will not expect such unpleasant surprises as swelling from it.

- Material does not change geometry, does not "leave", does not "hump".

- Not afraid of decay and fungal attack.

- Certain types of boards have an attractive option to restore their appearance. The corduroy board can be quickly rehabilitated with a brush or sandpaper with your own hands.

- Minimal care. For this, decking is especially loved. It does not require intensive cleaning. Unless once a year you can arrange a general cleaning and set aside a couple of hours for the terrace floor.

An important point! If a light decking is chosen, it is the same as with another floor covering - there will be traces of dirty shoes, spilled drinks, etc. All this is easy to clean, but usually the owners of country houses prefer a less soiled dark terrace board.

There are a lot of pluses, and the critic in the buyer always busily asks: “What about the minuses?”. They are, of course. How serious is always subjective.

Cons of WPC decking.

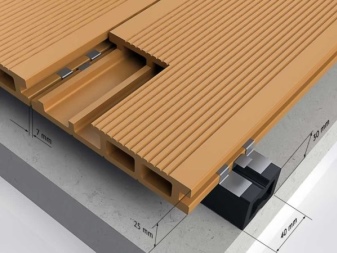

- Significant thermal expansion. That is, problems may arise during installation (but not necessarily). There are such types of WPC where this negative property of the material is not felt at all. But often it is necessary to select a special mount - these can be mounting plates-clamps.

- You can wet, you can't drown. If a dashing summer rain runs over the deck, nothing bad will happen. But if you make a good puddle on the decking, he “won't like it”. And here everything is decided even during the installation process: you need to lay it correctly, so that the water slides off the surface faster. If the flooring is not solid, there is no problem, the water will go away soon. If the laying is solid, you need to orient the direction of the grooves so that it is easier for the water to drain.That is, organizing the slope closer to the edge of the court is a reasonable measure for decking.

WPC contains at least 50% natural wood. And even all 70%... That is, it is simply incorrect to compare decking with a stone or tile in terms of strength. Of course, if you drop a very heavy object on the board, this can lead to its deformation. If the board is hollow, it is possible that the top wall will break. But usually the buyer is ready for these nuances and understands that a wooden floor (even if it is only half) is incomparable with a stone one.

Varieties

In this section, we will talk about what a decking board can be in terms of its technical features (namely, a decking made of WPC).

By the method of flooring

Sometimes the flooring is solid, seamless, and sometimes the one that comes with gaps. The solid one is distinguished by a tongue and groove (the analogy with a tongue-and-groove board is obvious). And the board fits almost without gaps - they are so insignificant that you can not count them. The coating, however, allows moisture to pass through, only the moisture will leave slowly. When it is raining for a long time, there may be puddles on the floor. This is a minus. And the plus is that small debris will not clog in the cracks in the flooring. And in heels on such a floor it is easier to walk.

A composite board with a non-continuous deck is laid with a visible gap. Moisture will definitely not stand in puddles, it will quickly pass through the gaps under the flooring. The issue of thermal expansion is immediately removed. However, what was a plus in the case of the first option will become a minus - throwing parties on the terrace, sporting high-heeled shoes and dancing is not very comfortable. But if there are no such goals, then everything is fine.

Also, the boards are divided:

- on full-bodied - there is a solid composite, there are no voids, which is excellent for places that require an increased load;

- hollow - the option of less strength, but it is quite suitable for private estates, because the corpulent one is chosen for places of high traffic, that is, cafes, piers, etc.

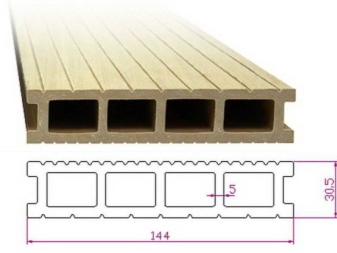

An incomplete board is also called a honeycomb board. Her profile can be either private or open. In the first case, the structure contains two horizontal surfaces, between which there are jumpers. In the second, there is only one horizontal surface, below there are only edge endings. This type will be cheaper, but it can be used only in low traffic areas.

By types of surfaces

The buyer is also interested in the texture of the board.

The choice is presented as follows.

- Decking with grooves, grooved... Or otherwise - "corduroy" (this type of boards is better known under this name). The good thing about the board is that it does not slip, almost does not wear off. Only it is a little more difficult to remove it, because the debris remains in the grooves, you have to get it out.

But if the farm has a "Körcher", there will be no problems with cleaning.

- Decking with imitation wood. This option is more slippery, abrasion threatens it faster. And at the same time it costs more. But it is easier to clean it - you can just walk on the floor with a broom, and everything is clean.

It is considered a very profitable option for those who are used to going out on the terrace barefoot, especially if it is located not in front of the main entrance (with its high traffic), but behind the house. They often walk in slippers and barefoot, which is why this type of smooth board is preferable.

It is worth saying a little more about the grooves. They can be brushed and sanded. The latter are smoother, but the brushed ones are deliberately made slightly rough. But both types of surfaces are prone to restoration. A brushed board can be restored with sandpaper, and a polished board can be restored with a metal brush. Do not be afraid that after grinding the color will go away: the material is colored in bulk.

But it is impossible to restore a board with imitation of wood, just as it is impossible to restore, for example, plastic, plastic floor. The erased relief cannot be returned.

Dimensions (edit)

The polymer composite board does not have a standardized size. That is, it is impossible to find a table of standards. It all depends on the manufacturer's decision. They look mainly at the thickness and width.For example, a common request for a hollow deck is: thickness 19-25 mm, width 13-16 mm. But the parameters can go up to 32 mm thick and 26 cm wide. It is important to see what the partitions will be. If they are thinner than 3-4 mm, this is not the most reliable option.

No matter how wide and thick the board is, it will fit in the standard way - on logs (that is, square or rectangular bars). The thinner the board, the closer the logs are - otherwise the coating may bend. The optimal size of the board in terms of thickness will be 25 mm (+/- 1 mm). This thickness is sufficient for flooring in a country house.

Width has the advantage of fastening: the wider the board, the less fastening is required.

Popular manufacturers

Probably, only people who are very involved in repair and construction business know the rating of brands of manufacturers in Russia and abroad. There are really not many names on hearing.

The best manufacturers include:

- Waldeck;

- PolyWood;

- Darvolex;

- Terradek;

- Werzalit;

- MasterDeck.

A manufacturer's reputation is better than any advertisement. You should look closely, first of all, to those brands that have websites or actively conduct social networks.

It is more convenient to choose, it (at least preliminary) can be made from home: see all the options, ask the price in a calm, unhurried atmosphere.

Nuances of choice

What if the buyer is already in the building market (or is going at the board), and when buying can only rely on the help of a consultant? I would like, of course, to understand the quality of the board myself. There are some tricks that can help keep you from making bad choices.

So, what should you pay attention to.

- On board structure... You need to choose the one that outwardly does not raise doubts about homogeneity. If there are areas with different surfaces on the board, this is already an alarm bell.

- Jumpers... They should be the same in thickness, and there should be no complaints about the sharpness of the edges.

- Waviness is excluded. To do this, you need to view not only the front and bottom faces, but also the sides.

- Equality of chamfers and grooves... One distance, one depth - if symmetry is broken, it's time to move on to another composite deck board.

- Crumbs and bundles on the saw cut - no. This product is not of the best quality. It can be sold at a discount, but if the price is not reduced, it is a minus of the seller.

Of course, the buyer will not be allowed to try to break the displayed goods. But, if this is a good building market, there are samples there that you can touch, examine in detail, and even try for a break. Because a good decking board, if you try to break it, will not bend. The fact that it will crack, begin to crumble and there is no need to talk!

There is one more trick: you need to ask the consultant to show all the colors of the board. If the manufacturer is cool, then the assortment will definitely include a light decking. A light decking is a guarantee of using good quality wood. If the manufacturer proposes to cover the terrace, balcony, street with only a dark-colored floor, most likely, normal wood has been replaced by bark.

That is, you can choose a good decking using the color palette analytics. The move is unexpected, but working.

Installation methods

Most often, the board is laid on logs - we have already mentioned this above. But there is also a second option, it is called "concrete base". True, not every board will lie on the concrete. And the platform for such a base should be perfectly flat.

As for the lags, they are wooden, made of WPC (like the decking itself) and made of a profile pipe. Wooden logs are treated with an antiseptic, impregnated with all compounds that will not cause a conflict between wood and soil.

If, nevertheless, it is decided to lay the board on concrete, it can be of two options: tile or screed. And the board can also be laid on piles using a strapping. If you have to deal with an uneven base, then you will need to expose the lags with gaskets. Rubber ones are more suitable, although some craftsmen cut glass insulation and its analogs into squares.

If you ask an experienced craftsman what it is better to mount the decking on, he will say - take the same WPC. That is, to combine like with like. And this is logical. In such lags there is a special groove for fasteners.

Such a system is usually offered in the building market. But if you use fasteners from other manufacturers to these lags, there may not be contact.

After the deck board is laid, it is required to close the sides of the resulting platform. You can use lining-strips of the required width, a corner made of wood-polymer composite. Pay attention to the thickness of the corner: it cannot be thin. But if the seller offers an aluminum corner covered to match the board, this is the best option - this way there will be no rapid abrasion of the material.

And if the terrace is adjacent to the house, the option of a WPC plinth is not excluded. And this joint with such a skirting board is also a good choice: it is inexpensive, the colors are different.

Review overview

A modern choice without analytics of reviews is a rarity. The seller needs to sell, and he does not voice certain points. And on specialized forums, sites, resources for repair and construction, you can find real user reviews.

By examining several of these sites, you can bring together the most frequently encountered comments and remarks.

- Composite boards are very different in terms of price, composition, and quality.... Therefore, there is no consensus on whether to buy or not. Those who saved money, purchased an uncertified product or not of the highest quality will write negative reviews. But this is only personal experience of using a priori losing product.

- For verandas, terraces, gazebos, composite boards are competitive with larch products. Many note that they doubted when buying whether the board will survive the winter, but it has withstood more than one season, and the wind, contrary to many storytellers, has not pulled out the fasteners "by the roots."

- The market for offers is still not large enough. Yes, and such decking began to be used relatively recently. Along with quality manufacturers, smaller companies appear that simply dispose of waste from the woodworking industry, investing it in decking. And it turns out not the best option. This is not a reason to abandon the board, you just need to look at whose products you have to buy.

- Some owners are confused that the WPC decking does not particularly outperform the larch board. But these are really close product categories, and there cannot be a huge difference. Better is only a deck board made of exotic tree species, the price of which is too high for many buyers.

The choice is responsible, you need to remain realistic and "turn off" excessive skepticism at the same time. There is no perfect flooring, and the one that is close to it is very expensive.

The comment was sent successfully.