How to bleed a hydraulic jack?

According to current statistics, the number of motorists making a choice in favor of hydraulic lifting devices is constantly increasing. This is primarily due to the maximum simplicity of the design and the direct operation of such equipment. However, it also requires competent care and periodic maintenance. That is why you should know how to properly pump a hydraulic jack without contacting specialists.

When exactly is pumping needed

It is important to remember that the life of any tool and equipment without maintenance is limited, and hydraulic jacks are no exception. On the one hand, these devices are classified as the most reliable and durable, however, and they require regular maintenance. Most often, users have to deal with malfunctions that affect the pressure inside the cylinders.

As a result of such problems, the height of the rod lift is significantly reduced, as well as the ability to hold the load. At the same time, the performance of the equipment can decrease both gradually and sharply. In such situations, one of the effective ways to solve the problem can be pumping the jack, during which it will be necessary to expel air from the system and replenish the supply of working fluid.

To eliminate any malfunction as quickly as possible, you must first determine its causes. Timely and accurate identification of the vulnerability of the mechanism will help to quickly restore its performance.

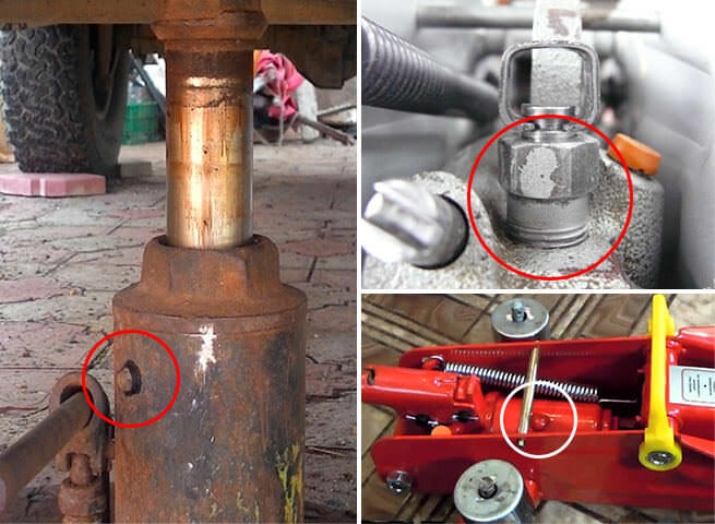

It is no secret that it is the oil that acts as a working fluid in any hydraulic device that is responsible for creating the pressure required to lift and secure loads. Based on this, we can conclude that most of the problems are associated with it. Airiness of the system leads to the following problems:

- reduction of the working length of the rod;

- the appearance of spring damping of the stop at minimum loads;

- significant slowdown in ascent;

- reducing the lifting capacity of the jack.

In the overwhelming majority of cases, air in hydraulic cylinders appears due to a decrease in the amount of working fluid. If the bypass valve is twisted too far, oil may simply leak out if the jack is tilted.

It is worth considering that even with proper transportation in such cases, the volume of the liquid decreases over time. That is why it is highly recommended to constantly monitor the position of the specified valve.

Another source of air can be a damaged, worn out or improperly installed hydraulic pump piston o-ring. When operating the jack horizontally and upside down, the chamber may gradually fill with air. In such situations, the amount of oil in the second container may remain normal.

Most often, the source of all troubles is the airiness of the cylinders of the hydraulic jack and the loss of tightness of individual elements of the structure of the lifting equipment. However, in practice, one also has to deal with the failure of check valves. Due to the fact that the locking ball, supported by a spring, is knocked off, the working fluid ceases to collect in the desired chamber. In such situations, before pumping the jack, you will have to completely disassemble it and replace the damaged elements.It will be more rational to entrust the execution of such work to experienced specialists of the service center.

Instructions

Initially, it is worth deciding what exactly is meant by "pumping" in relation to modern lifting mechanisms. We are talking about a set of actions aimed at displacing air from hydraulic cylinders. In this case, the whole process is reduced to pumping the working fluid with a pump. This is what became the determining factor in the appearance of the name of the procedure, which is one of the most important points in the maintenance of lifting devices.

At the same time, it is worth noting that it is possible to get rid of air in the jack system without using the mentioned pump.

Those who have at their disposal an old hydraulic jack or a relatively new model of modern lifting equipment with clear signs of airiness, need to know how to quickly cope with such a problem. A large amount of relevant information can now be found on the net.... First of all, it should be noted that to effectively restore the device's performance, you will need a standard tool arsenal, as well as about 300 ml of ordinary mineral oil or a special fluid for hydraulic systems.

To effectively pump a bottle-type hydraulic jack, you will need to perform the following steps.

- First of all, it is necessary to find a filler hole, which is sealed as tightly as possible with a rubber stopper. In most cases, it is located at the top of the device. Taking into account the design features of different models, the plug can be recessed into the body or protruding above it.

- Open the oil filling hole by carefully pulling out the plug to avoid damaging it.

- Drain off all working fluid in full. It is worth considering that this measure is relevant in cases where it is required to service an old hydraulic jack, which has been actively operated for a long time without maintenance. To completely remove the remaining oil, unscrew the bypass valve and lower the piston all the way.

- Flush the cylinders using special fluids, as well as kerosene or oil, which will be filled afterwards. To do this, it is necessary to pour the flushing agent through the aforementioned hole, by pumping to raise the piston to the highest point, and then open the valve and lower the stem to the stop. This procedure must be repeated several times.

- Fill the hydraulic cylinder with oil by placing the bottle jack in its working, that is, vertical position. Experienced users and experts advise using a syringe when doing this.

- After the container is filled to the maximum level, the bypass valve is tightened all the way. At the next stage, with up / down movements, the piston of the device is raised to the stop.

- After that, it is necessary to slightly unscrew the valve and manually lower the piston with the filler hole open. This sequence of actions is repeated several times.

- If the described algorithm did not lead to the desired results, and air remains in the system, then you can unscrew the shut-off valve a few turns, raise the piston manually and lower it sharply. In this case, the use of a pump is excluded. Such manipulations are repeated several times, and with each approach, the length to which the stem extends decreases by 1 cm. As a rule, such drastic measures allow you to quickly get rid of air in the hydraulic system.

Hydraulic slide-type lifts are characterized, first of all, by increased lifting capacity. In this case, the main performance indicator directly depends on the tightness of the system and the pressure created in the working chambers. To maintain the full performance of rolling models, they need to be pumped periodically.

Contamination and air ingress can be a source of problems with this category of hydraulic jacks. There are several ways to remedy the situation. The first option for pumping rolling equipment involves the following steps:

- open the oil filler plug;

- unscrew the overflow valve;

- pump the working cylinder with quick movements;

- screw the valve all the way in and close the filler hole tightly.

Unfortunately, in some situations, the manipulations described above cannot fully squeeze out the air from the hydraulic system. At the same time, many are interested in how to identify its remains in the cylinders of the jack.

It is worth noting that during the operation of the lifting mechanism, the air will certainly show itself. Its presence will be evidenced by the poor operation of the device or its complete failure.

In such cases, you will need to find a shut-off needle, which is an integral part of the design of any modern sliding hydraulic jack. It turns out 2-3 turns, after which, in manual mode, the piston should be extended several times to the stop and returned to its original position. As a result of such manipulations, as in the situation with bottle models of equipment, the air will be completely squeezed out of the system.

Recommendations

It is well known that the guarantee of long-term and full-fledged functioning of any mechanism, regardless of its purpose, is competent operation and timely, high-quality service. That is why motorists are advised to know how to properly pump an automobile hydraulic jack with their own hands. This will maximize the life of the equipment and ensure the safety of work with its use.

The operating rules for hydraulic jacks, including safety precautions, are developed taking into account the many years of experience of tool manufacturers. It is necessary to pay attention to the following important points:

- Frequent overloads and lifts to maximum heights lead to inevitable equipment failure. Curvature of the stem inevitably leads to air penetration, and pumping in such cases will be useless.

- The jack itself must be installed on a hard, as flat surface as possible. Similar requirements apply to the stop point on the elevated vehicle or other load.

- When descending, it is required to smoothly unscrew the bypass valve exactly one turn, otherwise the working fluid will move too quickly between the compartments, which will lead to the release of the load in jerks, and will also increase the risk of airborne air.

- Proper transportation of the lift will help prevent the need for pumping. Bottle jacks and rhombic jacks should be transported in an upright position, and with a roll-up structure, horizontally.

- The care of the moving parts of the device deserves special attention. This means, first of all, the elimination of the risk of corrosion on mirror surfaces, which negatively affects the performance of the equipment.

It is important to remember that pumping hydraulic jacks is also a preventive measure. It often helps prevent serious breakdowns and, consequently, avoid costly repairs or the purchase of a new lift. It means that it is recommended to pump the jacks periodically. In this case, the frequency and number of pumping is determined by the intensity of the use of the jack.

So, at the service station, a similar procedure is repeated at least monthly. With garage, rare operation, it will be enough to pump it several times a year. Unscheduled maintenance may be required in the following cases:

- The presence of a large amount of foreign particles in the liquid. Such impurities can significantly reduce the efficiency of jacks.

- The formation of bubbles, indicating a violation of the tightness and airiness of the hydraulic system.

- Drastic and significant reduction in working capacity. As soon as the equipment stops lifting the weights declared by the manufacturer, the cylinders should be pumped.

Many modern jacks are one-piece construction. This means that it is not always possible to bulkhead the device. In such situations, the optimal solution would be to pump the mechanism.

A more detailed overview of pumping a hydraulic jack is presented in the following video.

The comment was sent successfully.