All about hydraulic jacks

Working with a car and lifting other loads cannot do without jacking devices. To avoid problems, you need to choose the right model correctly. And that is why it is so important to know everything about hydraulic jacks, about their features and application nuances.

Description

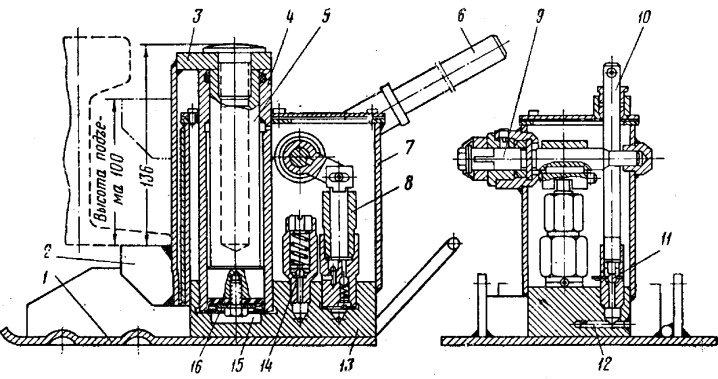

The device and structure of a hydraulic jack is relatively simple. These devices have a universal purpose, can be used in a variety of areas, for various jobs and manipulations. The overall simplicity of the system increases its reliability. The case of any model is made of a strong, reliable alloy of a special formulation. An important property of such an alloy is its corrosion resistance.

Working chamber the hydraulic jack has a mirror surface. Piston assembled from several constituent elements. To restrict the movement of liquid, apply special valve.

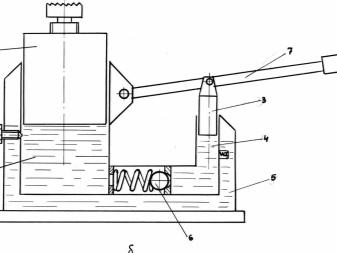

A manual or automatic mechanism helps to start moving the oil. Models with paws differ from conventional models in that they are designed for a low grip.

Principle of operation

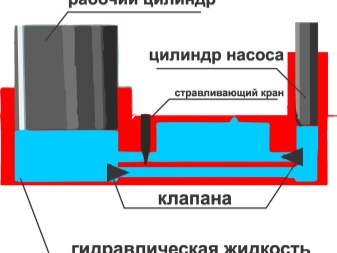

To understand the action of a hydraulic jack, you must first pay attention to the liquid that works inside it... It uses oils with reduced viscosity. They should not even contain trace amounts of water.

When the pump is running, special fluid enters the reservoir with a large cylindrical groove. The walls of the container are tightly enclosed by a movable rod, which is part of the piston. According to physical laws, when a container is overfilled with oil, it begins to squeeze all adjacent parts of the device. The body and valve are designed to withstand enormous pressures. Therefore, the only option for the development of events is the displacement of the piston upward.

Since the compressibility of the oil is very low, the piston will be held on its surface as firmly as on asphalt. A cutaway view of the hydraulic jack is shown in the figure.

Separate hydraulic jacks are used to tension the reinforcement. But they can also be designed to solve a number of other tasks (depending on power and characteristics):

- raising cars and other vehicles;

- compression of very tight and powerful springs;

- connection of parts of a building structure at a height;

- repair work;

- other situations when you need to work with a heavy load, fixing it for a long time.

Views

Consider the most common types of hydraulic jacks.

Horizontal

For the most part, such a device has screw version... Skids are supplied special screw... The total lifting capacity can reach 15,000 kg. Such devices are used in isolated cases when there are increased requirements. Basically, the horizontal jack is used by drivers of massive cars. For light vehicles, increased carrying capacity is not required.

Manual

Car owners are also looking at manual models. They are relatively simple. The price of the finished product is quite low and will suit most buyers. The reliability of the tool is guaranteed, but only with a relatively low load. Attempts to lift something very heavy will not be successful.

Cable

This type of jacks is not used in car services.... Its very name suggests that with the help of such devices, cable drums are lifted. The tool axis passes through the middle hole of the drum.The gap between the "cheek" and the installation surface of the racks is most often 0.05-0.1 m. Basically, such devices are used when you need to mount or rewind the cable.

Other

Quite widespread oil subtype of hydraulic jack. Oils intended for hydraulic systems of cars can be poured inside. But they will have to be selected carefully, taking into account the properties of specific substances. In some cases, use standard industrial oils.

Do not use brake fluid.

A glass or bottle hydraulic lift is divided into two communicating vessels of different cross-sections. This is a proven classic scheme. Inside install plunger pump. Such devices are often bought in a home garage for bodywork. But if their performance is not enough, you need to purchase a professional industrial cargo jack.

And sometimes they also use flat models. Their main working body is divided into 2 "plates". They are connected along the contour. For connection to the hydraulic system are used special fittings... The upper and lower plates are connected by special guides. Such systems can lift the load evenly, without sudden movements. Responsible for the reverse screw parts. But for home use they are more attractive lifts mini. Such furniture will be lifted, and they will help in repairs, and they will come in handy in the construction of an extension.

But it is imperative to mention also about models with external pump. A striking example of such a device is TOR HHYG. The lifting capacity can be from 2 to 200 tons. This equipment can be used both in construction and in motor vehicles where they work with heavy vehicles. The remote circuit is more stable, it allows you to place the device even on an uneven base. Three-rod jack - one of the subspecies of the bottle scheme.

This design has a large lifting height... At the same time, the presence of three rods at once guarantees relatively small overall dimensions. It is quite convenient to transport and store such devices. Long stroke option in general, it is characterized by increased functionality. But the short-travel versions rarely pay off.

The term "pulling jack" speaks for itself. It not only lifts loads, but also creates a pulling momentum. This technique is used to connect ship hulls. It will also be useful for joining other metal structures that are planned to be welded. Of course, almost all types of lifts can be made with a pressure gauge.

This provides more effective control over the internal pressure in the instrument, so it will be easier to regulate the force created on the stem.

This is an autonomous and very practical device in everyday life.... It can be useful for weighing even fairly heavy loads. A jack double-ended with hollow stem becomes an excellent part of press machines and other industrial accessories. It can be used for pressing and extrusion of individual parts, tensioning of reinforcement and ropes.

The drive for such a lift can be:

- foot;

- manual;

- electric pump.

Important: the vast majority of models (including universal and stationary jacks) are made with a movable plate. But the rack-mount type also deserves attention. It involves the use of 1 or 2 screws.

Such a device will allow lifting up to 3000 kg. The disadvantage of such a scheme is only a significant mass of the jack.

V wedge system everything, except for the drive itself, is made purely mechanically. The rotation of the screw moves the special wedge horizontally. This is a versatile and fairly reliable technical solution. Of course, they try to buy any jack with an oil station. Modifications with an oil filling station are the most practical and convenient, they allow you to optimize the filling of technical fluids.

But if you look into the most ordinary garage, then there you can also see scissor jack. Feature of execution - a pair of diagonal metal blocks. Their expansion and contraction occurs in the same way as in household scissors. With this technique, sometimes only one corner of the vehicle is lifted. However, the options do not end there.

There is, for example, flanged versions... They already contain a nut with a special flange as standard. Cylindrical jack Is just a common form. More can hardly be said about him. In principle, it can also be used for a garage crane.

Some enthusiasts buy old ones altogether. tank lifts. They are distinguished by increased reliability and are designed to lift several tens of tons of cargo. This is what you need to work with heavy vehicles or large construction projects. But in many cases it is more correct to use classic trapezoid. Yes, it will not provide a high lift, but it will still cope with the main function quite well.

Model overview

When talking about the best small jack designs, you should pay attention to model "DN30P14"... The low load mechanism is made in a one-way design. The stem return is provided by a special spring. Its stroke reaches 1.4 cm. The maximum carrying capacity of a device made in Russia is 30,000 kg.

Other technical parameters:

- pickup at a height of 58 mm;

- oil tank capacity - 0.58 l;

- own weight - 3.94 kg.

The device is suitable for use in confined spaces. It can be used when leveling bridge spans. The highest hydraulic pressure is 70 MPa. Permissible temperatures are not lower than -15 and not higher than +50 degrees. The jack is coated with durable powder paint.

It can be useful to take a closer look at the high, long lifts. For example, to the model "Ulyanovsk URD-01_1t". It is a decent quality reliable device for field work with a car. Wherever problems arise, repairs are greatly simplified. The highest lifting capacity is 1 ton, and the highest lifting height is 0.41 m.

When choosing vertical jacks according to the characteristics, it is worth taking a closer look at the modification KRAFTOOL KRAF-43463-4. Double rod mechanism has a bottle version. It lifts up to 4000 kg of cargo. The smallest grip height is 0.17 m. The load will be lifted to 0.42 m.

The rating of the best jacks deservedly also includes models on wheels. For example, 3T Gigant HTJ-3. It is equipped with a support serrated bowl, therefore the load is fixed reliably, breakdown is completely excluded. Important: the manufacturer recommends using its design in conjunction with a safety stand to reduce the risk of injury. The special coating reduces the risk of corrosion.

Other features:

- pickup at a height of 0.135 m;

- lifting to a height of 0.4 m;

- total weight - 16.7 kg;

- total lifting capacity - 3000 kg;

- the handle for turning and the case are missing.

It is worth thinking about buying branded Chinese model jacks Sorokin FrogLine Jack 3.432. The total load reaches 3500 kg. The model can be used in tire centers and various service stations. Net weight - 38 kg. The pickup takes place at a height of 0.135 m, and the rise goes up to a height of 0.495 m.

You can still consider JET 8.0 t JBJ-8 JE655558. This bottle jack is used both horizontally and even upside down. It will lift up to 8000 kg of cargo. The stroke of the rod reaches 0.125 m. The mass of the jack is 6 kg.

Also good hydraulic devices can be considered:

- Ombra OHT150;

- Stels 51133 Quick Lift;

- Matrix Master 51035;

- Kraft KT 800115.

How to choose?

There are a lot of modifications to hydraulic jacks, so you need to carefully choose the device, primarily based on their own needs... So, for heavy-duty trucks, the optimal choice may be bottle device. It is also possible to use other constructions, but only when there is a clear understanding of exactly why they are needed. It is worth considering that the lifting height of the bottle lift does not exceed 0.5 m.

Quite a convenient solution can be rolling jack. True, it is quite cumbersome. The mass of such models sometimes reaches 10-40 kg. They can only be placed on flat, solid areas. Therefore, such products are in demand mainly in car services and official repair services.

Be sure to consider carrying capacity. Its optimal value is determined simply: 100-300 kg are added to the passport curb weight to compensate for the additional load. If you need to change a wheel, a lift of 0.3-0.5 m is sufficient. For more serious pit work, the height should be higher. A very low pickup height is needed for low-slung machines with a ground clearance of less than 0.1 m.

If you plan to work at a summer cottage, you can limit yourself bottle hydraulic jack with a bearing capacity of up to 10,000 kg. More powerful options are needed for professional construction crews. But you can also choose a rolling hydraulic device with the same limitation in terms of carrying capacity.

But models with a screw mechanism sometimes lift up to 50,000 kg. To accurately determine this parameter, you sometimes need to turn to professionals.

How to use?

As already mentioned, the hydraulic lift can only be refueled strictly defined liquids. Best of all, only those indicated in the instructions. Before starting work, you need to make sure that the load and lifting height are correct. Jack storage should take place only in specially designated dry, clean and warm places. In the trunk of the car, it is placed only in the place provided by the car manufacturer.

Lower hydraulic jack any design is easy. You just need to raise it to a level that allows you to pull the device out. If it is necessary to lift the car, they put it on the hand brake, and the wheels remaining on the ground are blocked. The point of installation of the jack under the body sill depends on what exactly is planned to be lifted.

Important: when a rolling device is used, simultaneously with the lifting of the plunger, it should gradually roll under the bottom of the machine.

Some designs can be used upside down. But only if it is expressly stated in the instructions.

It is categorically unacceptable:

- push the lift against the bumper;

- do something under the body of a car that nothing but a jack holds;

- lift the machine coupled to the trailer;

- work on the roadway;

- use the ignition and start the engine in a raised car;

- prop it up with bricks, stones.

Periodic maintenance of the jack cannot be reduced to mechanical cleaning (although this is, of course, very important). Hydraulic oil must be added in a timely manner... And periodically it is also changed. The more intensively the device itself and its pump work, the more often it needs replacement. It is impossible to mix different compositions, even suitable separately.

Often problems are created by accumulating inside the hydraulic cylinder air. You can drive it out by opening the bypass valve and unscrewing the oil fill cap. Next, do a few quick clicks on the handle. The pump will pump the liquid, and there will be no air inside.

All rubbing parts are systematically coated with grease. And if you additionally check the device for oil leakage, then there will definitely be no problems.

The hydraulic bottle jack is presented in the video below.

The comment was sent successfully.