Polyethylene foam insulation: description and specifications

Foamed polyethylene is one of the new insulation materials. It is widely used for various types of tasks from thermal insulation of the foundation to sheathing of water supply pipes. Excellent heat retention characteristics, stable structure, as well as compact dimensions determine the high efficiency and increasing popularity of this material, which is also durable.

Peculiarities

Production

Highly elastic material is made of polyethylene under high pressure with the addition of special additives, for example, fire retardants, substances that prevent the fire of polyethylene foam. The production process is as follows: granular polyethylene is melted in a chamber, and liquefied gas is injected there, which promotes foaming of the material. Next, a porous structure is formed, after which the material is formed into rolls, plates and sheets.

The composition does not include toxic components, which allows the material to be used in any segment of construction, and not only in industrial facilities and in places isolated from humans. Also, during the production process, a layer of aluminum foil is applied to the sheet, which serves as an effective heat reflector, and to enhance the heat-insulating properties it is also polished. This achieves the level of heat reflection in the range of 95–98%.

In addition, during the production process, various characteristics of polyethylene foam can be modified, for example, its density, thickness and the required dimensions of the products.

Specifications

Foamed polyethylene is a material with a closed-porous structure, soft and elastic, produced with various dimensions. It has a number of properties characteristic of gas-filled polymers, including the following:

- density - 20–80 kg / cu. m;

- heat transfer - 0.036 W / sq. m this figure is lower than that of a tree with 0.09 W / sq. m or such an insulating material as mineral wool - 0.07 W / sq. m;

- intended for use in an environment with a temperature range of -60 ... +100 С;

- powerful waterproofing performance - moisture absorption does not exceed 2%;

- excellent vapor permeability;

- a high level of sound absorption with a sheet with a thickness of more than 5 mm;

- chemical inertness - does not interact with most active compounds;

- biological inertness - fungal mold does not multiply on the material, the material itself does not rot;

- huge durability, under normal conditions not exceeding the established operating standards, high-quality polyethylene retains its properties for 80 years;

- biological safety, the substances in the foamed polyethylene are non-toxic, do not provoke the development of allergies and other health problems.

At a temperature of 120 C, which is beyond the operating temperature of the material, the polyethylene foam is melted into a liquid mass. Some components newly formed as a result of melting can be toxic, however, under normal conditions, polyethylene is 100% non-toxic and completely harmless.

Applying insulation will be very simple if you follow all the recommendations.

Compared to other materials, reviews about it are more positive.Doubts about whether it is dangerous are in vain - the material can be safely applied. Another positive fact - it does not leave stitches.

Insulation marking

Heaters based on polyethylene are divided into many types, marking is used to indicate the presence of certain features, namely:

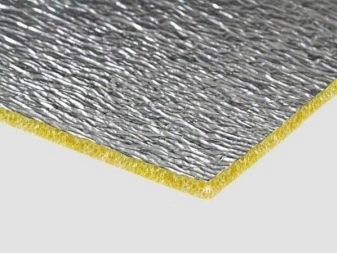

- "A" - polyethylene, covered with a layer of foil on only one side, is practically not used as a separate insulation, but only as an auxiliary layer with other materials or a non-foil analogue - as a waterproofing and reflective structure;

- "V" - polyethylene, covered with a layer of foil on both sides, is used as a separate insulation in interfloor ceilings and interior partitions;

- "WITH" - polyethylene, on one side covered with foil, and on the other - with a self-adhesive compound;

- "ALP" - material covered with foil and laminated film on one side only;

- "M" and "R" - polyethylene coated with foil on one side and corrugated surface on the other.

Application area

Excellent properties with small dimensions allow the use of foamed polyethylene in various fields and is not limited to construction.

Common options are:

- during the construction, repair and reconstruction of residential and industrial facilities;

- in instrument and automotive industry;

- as a reflective insulation of heating systems - it is installed in a semicircle near the radiator on the side of the wall and redirects heat into the room;

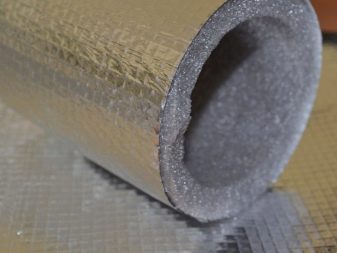

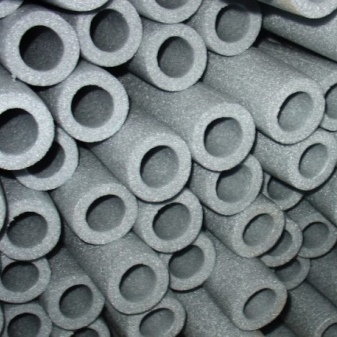

- for the protection of pipelines of various nature;

- for stopping cold bridges;

- for sealing various cracks and openings;

- as an insulating material in ventilation and air conditioning systems, and some types in smoke extraction systems;

- as thermal protection during the transportation of goods requiring certain temperature conditions and much more.

Recommendations for use

The material consists of several layers, each of which has its own purpose. With a certain specificity of the application, some of the properties do not appear, which makes them useless. Accordingly, in such a situation, you can use another subspecies of polyethylene foam and save on unnecessary additions, for example, a foil layer. Or, conversely, the type of material does not correspond to the specifics of the application and is ineffective due to the lack of the necessary qualities.

The following options are possible:

- When poured with concrete, placed under a warm floor or in other similar situations, the foil surface does not give a reflective effect, since its working medium is an air gap that is absent in such structures.

- If polyethylene foam without a foil layer is used to reflect an infrared heater, then the efficiency of re-radiation of heat is almost absent. Only heated air will be retained.

- Only a layer of polyethylene foam possesses high heat-insulating properties; this property does not apply to an interlayer of foil or film.

This list only gives an example of the specific and implicit subtleties of using polyethylene foam. Having carefully read the technical characteristics and having estimated the upcoming actions, you can determine what and how to do better.

Views

On the basis of foamed polyethylene, many types of insulation are produced with various purposes: heat, hydro, noise insulating slope. There are several options that are most widespread.

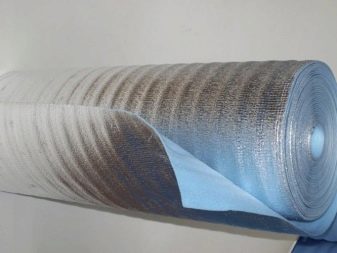

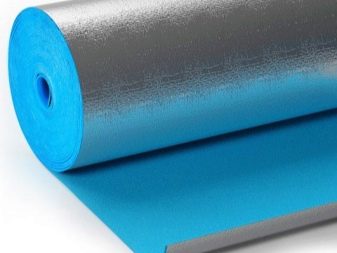

- Polyethylene foam with foil on one or two sides. This type is a variant of reflective insulation, most often implemented in rolls with a sheet thickness of 2-10 mm, the cost of 1 sq. m - from 23 rubles.

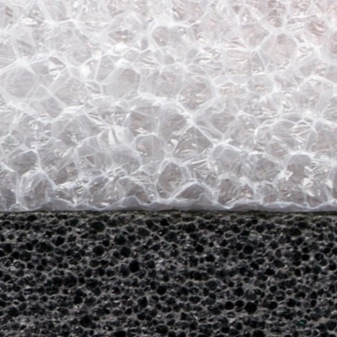

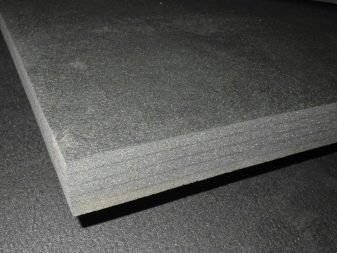

- Double mats made of foamed polyethylene. Refers to the materials of the main thermal insulation, used to cover flat surfaces, such as walls, floors or ceilings. The layers are interconnected by thermal bonding and are completely sealed.They are sold in the form of rolls and plates with a thickness of 1.5–4 cm. The cost of 1 sq. M. m - from 80 rubles.

- "Penofol" - a branded product from a well-known manufacturer of building materials of the same name. Polyethylene foam of this type has good noise and heat insulation. Consists of a perforated polyethylene foam sheet with a self-adhesive layer for easy installation. It is sold in rolls 3–10 mm thick with a length of 15–30 cm and a standard width of 60 cm. The cost of 1 roll is from 1,500 rubles.

- "Vilatherm" - This is a heat-insulating sealing harness. It is used for thermal insulation of door and window openings, ventilation and chimney systems. The working temperature of the product fluctuates in the range of -60 ... +80 degrees C. It is realized in hanks with a bundle section of 6 mm. The cost for 1 running meter is from 3 rubles.

Advantages and disadvantages

New technologies make it possible to create polymer materials with excellent performance, exceeding the desired parameters for natural materials.

The positive qualities of foamed polyethylene include:

- the lightness of the material ensures simple and convenient installation without the expenditure of physical strength;

- in the range of operating temperatures - from -40 to +80 - can be used in almost any natural environment;

- almost absolute thermal insulation (thermal conductivity coefficient - 0.036 W / sq. m), preventing heat loss and cold penetration;

- the chemical inertness of polyethylene makes it possible to use it together with aggressive materials, for example, lime, cement, in addition, the material does not dissolve with gasoline and engine oils;

- powerful waterproofing properties provide additional protection against moisture, which, for example, increases the service life of metal elements covered with foamed polyethylene by 25%;

- due to the porous structure, even with a strong deformation of the polyethylene sheet, it does not lose its properties, and the memory of the material returns to its original shape after the end of the impact on the sheet;

- biological inertness makes foamed polyethylene unsuitable for food for rodents and insects, mold and other microorganisms do not multiply on it;

- given the non-toxicity of the material, in addition to the combustion process, it can be used in any premises associated with human life, for example, in private houses or apartments;

- simple installation, the material is fixed without any problems with various fixing means, it is easy to bend, cut, drill or process in any other way;

- given the outstanding thermal insulation properties, its price is lower than that of similar polymers with a similar purpose: expanded polystyrene or polyurethane foam becomes even more profitable;

- high sound-insulating properties, which are manifested with a sheet thickness of 5 mm or more, make it possible to use it as a dual-purpose material, for example, for simultaneous insulation and sound insulation of the walls of a private house.

Manufacturers overview

The range of polymer insulating materials is quite diverse, among many manufacturers there are several that differ in the manufacture of a quality product and have a positive reputation.

- "Izokom" - a manufacturer of polyethylene foam using modern equipment and innovative technologies. The products are sold in rolls and are distinguished by good sound insulation, durability, convenient installation and high vapor permeability.

- "Teploflex" - manufacturer of environmentally friendly polyethylene foam. Insulation sheets are characterized by their elasticity, which provides comfortable installation and resistance to tearing when stretched.

- Jermaflex Is a high-quality polyethylene foam with a wide range of operating temperatures. The polymer has excellent mechanical and sound insulating properties, as well as high resistance to aggressive chemical compounds.

- Quick-step - the product manufactured in the Russian Federation under a European license is fully certified and meets quality standards. High noise insulation, environmentally friendly composition, the ability to combine with various materials - this is only part of the positive properties of this material.

You will learn more about thermal insulation made of polyethylene foam in the next video.

The comment was sent successfully.