"TechnoNICOL" Carbon: types and use of heat-insulating material

In choosing insulation, many prefer the products of the TechnoNIKOL company. The brand is known for a wide range of similar products, offering customers 5 collections of thermal insulators. The Carbon series is one of the demanded lines and provides its own nuances of use.

Features and production

TechnoNICOL Carbon is extrusive polystyrene foam. These are carbon based insulation with a low thermal conductivity. Carbon microparticles are used in its production. This helps to reduce the level of thermal conductivity and increase the strength of the insulation. Due to the saturation with nanocarbon, the line of materials is characterized by a light silvery hue.

This is one of the best thermal insulation materials of the trade mark in terms of energy efficiency. It is distinguished by the stability of the geometric shape, regardless of the service life. It does not shrink like other varieties from other rulers. The line includes materials for hobbyists and professional craftsmen.

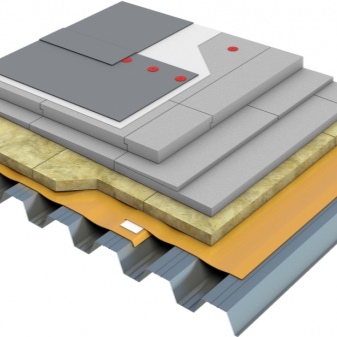

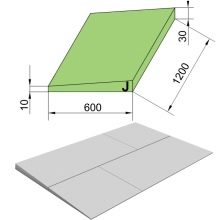

This allows a simple layman to cope with the installation of the material on his own, which significantly saves the budget. One of the features is the presence of slope-forming heaters in the line. These are slabs of different thicknesses, which outwardly resemble a slide with a slight slope. Wedge-shaped material is used when carrying out roofing work in order to avoid the formation of voids.

Materials differ in density, shape and purpose. They are characterized by a uniform distribution of closed cells. XPS boards are designed in accordance with GOST, they are a certified product. They have technical specifications and technical sheets with a description for each type of technical characteristics. For each of them, the brand checks, entering accurate data into the marking.

Even the method of transportation is subject to GOST. The company has developed basic recommendations according to which the material can be transported over a distance of up to 500 km in an open car. In this case, the material must be protected from direct sunlight and precipitation. Varieties for specific needs are produced taking into account the regulatory documentation of other manufacturers.

Heat insulation is packed in shrink film. Insulation can be stored vertically or horizontally using pallets, bars or other supports. Storage is also possible outdoors.

In this case, the material needs a canopy or protection from UV rays and precipitation.

Types and application

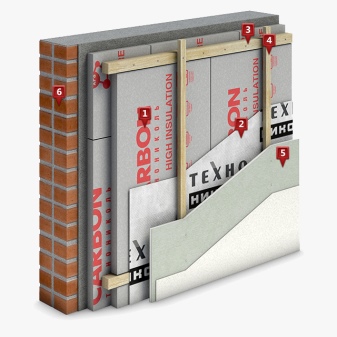

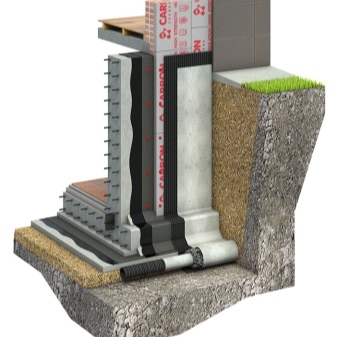

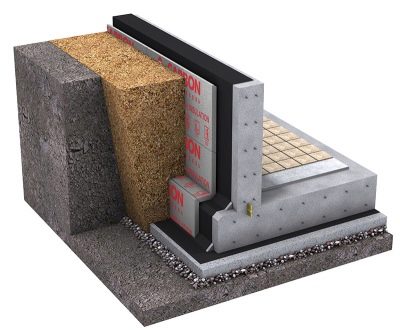

The TechnoNICOL Carbon line today includes 11 types of insulation. Depending on the type, they are intended for insulation of the foundation, wall and ceiling ceilings, and roofing works.

- Eco is a high strength material with a rigid base. This insulation is used to insulate cottages and low-rise buildings. He copes with the insulation of the facade, foundation, floor and roof.

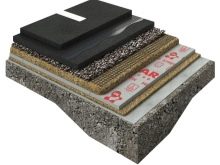

- Eco Drain - analogue for cladding wall drainage. Differs in the presence of drainage channels or ribbing. Application is micro-ventilation and insulation of flat roofs, getting rid of stagnant water.

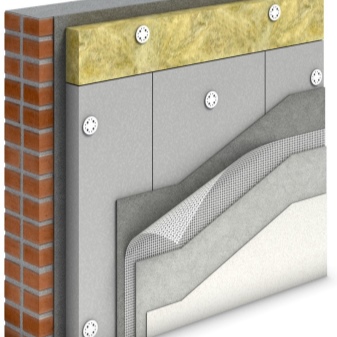

- Eso Fas - plates with characteristic milling. Their purpose is to insulate plaster facades and plinths. It is appropriate to use this insulation where the requirements for adhesion of tiles to the base are especially high.

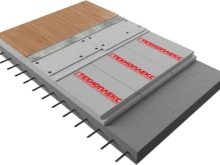

- Eso SP - a kind of version of the basement insulation based on the principle of the insulated Swedish plate. It is a particularly durable material that can withstand weight loads. It is used in frame structures that do not require a basement.

- Prof - professional XPS material in the form of rectangular slabs, used for almost all types of insulation, right down to the foundation. This is the material with the lowest thermal conductivity coefficient.

- Prof Slope - a separate version of slabs with a slope for roofing work. Sold as a set of sheets with different bias. It can be used where a slope and slope device is required in the valley for gutters.

- Sand mon - plates of the same thickness for the core of insulating sandwich panels. This is thermal insulation for monolithic housing construction.

- Sand PVC - analogues of the previous insulation. They are a development based on extruded polystyrene foam for further use in PVC sandwich panels.

- Sand VAN - another version of the core for sandwich panels. Unlike the two previous types, its purpose is to insulate insulated cars. It is used to insulate the bodies of freight vehicles.

- Solid type A - a variant with closed cells and a rigid substrate. Plates are used in civil construction. In addition to warming the foundation, they are used for sheathing operated and loaded roofs, as well as for warming the bases of heavy vehicles.

- Solid type B - an analogue with high technical and operational characteristics, a similar structure. The purpose of the material is to insulate the main area of the roadbed without removing the rail and sleepers. This is the best raw material for the installation of thermal insulation for railway tracks.

The different uses explains the importance of careful selection of insulation. In fact, it cannot be called universal, designed for all cases of construction. Taking this aspect into account will allow you to buy the desired insulation option. The company provides detailed information, specifying a list of properties of each material. Moreover, each type of product is marked with an image for greater clarity.

It shows packaging, sheets, their uniformity, ribbing or wedge-like shape.

Specifications

Physical and mechanical characteristics - a list of the properties of each type of polystyrene foam insulation. Depending on the different density and thickness, the indicators may vary.

The main characteristics are:

- compressive strength by linear deformation (150-200, 450 kPa);

- bending strength at different thicknesses (200, 450–700 kPa);

- thermal conductivity at t +25 + 30 degrees (0.031–0.033 W / m K);

- thermal conductivity under different operating conditions (0.034 W / m K);

- water absorption (no more than 2%);

- initial density (36–80 kg / m3);

- flammability class (G3, G4);

- flammability (B2);

- smoke formation and toxicity (D3, T2);

- operating conditions (-70 to +75 degrees C).

The parameters of the slabs are different. Standard dimensions of extruded polystyrene foam are (L x H x V) 1180x580x50 mm. The range includes slabs in length (L) 4000–4500 mm, width (H) 580–600 mm and thickness (V) 40–100 mm. For example, such parameters for Solid slabs. Analogue Carbon Eso in thickness is 1-10 cm. Length can be in the range of 1180-1200 mm. Option "Carbon Eco 35-300" can be used for thermal insulation of the facade of a brick house.

The compressive strength of the thermal insulation is different. In some cases, it is 300, 400 kPa. Varieties of the professional type are more durable and less heat conductive. Their vapor permeability coefficient is 0.014 mg / m h Pa.

Due to this, the thickness of the insulating raw material can be reduced.

Advantages and disadvantages

TechnoNICOL extrusion insulation has many advantages. It is used for indoor and outdoor insulation of buildings. It is worth highlighting the main advantages.

- They versatile... They can be used to insulate vertical, horizontal and inclined planes.

- Heaters variable... The buyer has the opportunity to choose between products of different price segments.

- Different focus insulation. The choice allows for high-quality thermal insulation of different planes.

- Durability. Extrusion heaters of a domestic brand do not need to be adjusted for several decades.

- They do not crumble and do not crumble over time, do not swell on contact with water, and are durable.

- These materials inert to chemical attack... They do not rot or decompose.

- Their improved thermal conductivity in comparison with other analogues of other collections.

- These materials are biostable... The structure does not attract the attention of rodents and insects.

- The thermal insulation of the company is antistatic. This eliminates the risk of the appearance and development of microorganisms and molds.

- Extrusion heaters environmentally friendly and are not afraid of moisture. It is not absorbed into the structure of the material.

The manufacturer produces products that are easy to install. Wherein sheathing can be done in different ways. However, the methods are united by the speed of work. Each product is marked with quality control. The brand tries to make products without prohibited foaming agents and flammable ingredients. Other varieties are insured in Alliance Insurance Company for a million euros.

In addition to the advantages, it is worth noting the disadvantages of these materials. According to research, extruded polystyrene foam of the Carbon series does not support fire, but it can melt already at t 60 degrees. In this regard, it loses its structure, starting to collapse. It is not always good to insulate walls with this material, which is associated with vapor permeability. It is more suitable for foundations due to closed pores. It can also be used for base / plinth and floor.

Buyers' opinions indicate that the density of the line in question is small. Sometimes buyers note that budget options are heterogeneous in structure. This leads to a reduction in their service life. The difference between the quality of elite and cheap materials is also obvious.

In order for the insulation to be reliable and durable, you have to buy expensive raw materials.

Technology and stages of installation

Installing extruded polystyrene foam yourself will not be difficult. If the facade is insulated, all the main types of work inside must already be done. This applies, including window, doorways, as well as the roof of the building.

Installation consists of several successive steps.

- The required amount of glue and insulation is purchased, taking into account the calculation of the number of packages.

- Prepare the right inventory to simplify the workflow.

- The insulation must be fixed on a flat base. To do this, the surface is leveled, obvious bumps are removed.

- In order for the glue to better hold the thermal insulation, you need to remove dust with a damp cloth. Then the surface should dry.

- You need to get rid of dirt and grease. They will reduce adhesion.

- After that, a layer of primer is applied to the surface. It is better to use a soil with the maximum penetrating power. This will align the structure of the base, bind dust and microcracks.

- Large cracks are covered with cement-based plaster. Then these places are primed again. The soil layer must dry before fixing the insulation.

- Marking is carried out and the profile is attached to the base. Its width should be equal to the thickness of the insulation used.

- Glue is applied to the back of the insulation using the dot method. You can apply it in stripes.

- The plate is applied to the base and pressed firmly. This is how the cladding of the required area is performed. In this case, one must not forget to fasten the plates to each other.

- After fixing, the waterproofing is laid. Usually, a thin film is used as it, which is put on the frame within 2-3 cm from the insulation.

- It remains to complete the finishing on top of the thermal insulation.

Selection Tips

In order for the quality of insulation with the TechnoNICOL extruded heat insulator to meet the required requirements, it is worth taking note of a few recommendations.

- Pay attention to the labeling. It indicates the purpose of each material.

- The purchase should be made in a trusted store with positive customer reviews.

- You can pre-scroll through the comments of professional craftsmen in the field of construction. In addition to the advantages, they usually indicate the disadvantages of a particular material.

The material is chosen taking into account a special calculation. This will allow you to buy the right amount. The formula is quite simple: the height of the walls is multiplied by the perimeter of the walls, then multiplied by the thickness, and then by the mark indicated by the manufacturer on the marking of cubic meters. With a wall height of 3 m, a perimeter of 24 m, an insulation thickness of 5 cm (0.05 m) and a volume of 0.36 m3 on the package, it turns out:

- 3 x 24 = 72 (m2);

- 72 x 0.05 = 3.6 (m3);

- 3.6 / 0.36 = 10 (packs).

Knowing the formula will allow you to save on the required amount: often a team of craftsmen deliberately overestimates this indicator in order to use it for other needs.

You will learn more about TechnoNICOL Carbon products from the following video.

The comment was sent successfully.