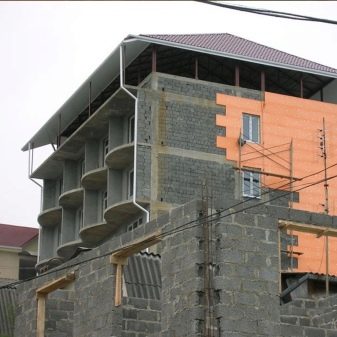

Penoplex "Osnova": features and benefits

In the modern world, more and more attention is paid to the comfort of housing. People are thinking about how to keep their home warm and at the same time save the resources needed to heat the room. Currently, the demand and supply of building materials for insulation of premises is quite large. One of the types of material that is used for warming rooms is penoplex.

Specifications

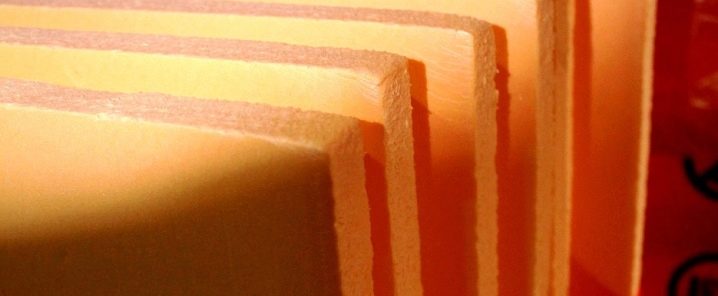

Penoplex "Osnova" is a Russian-made building material intended for insulation of premises. This material is obtained by extrusion from polystyrene. Extrusion consists in the fact that a heated polymer mass passes through special nozzles under pressure. At the exit, a durable insulation is obtained, which consists of small cells filled with air.

Insulation material Penoplex "Osnova" has excellent technical characteristics. The low weight of the insulation, due to the low density of the material, does not contribute to the weighting of the structure. At the same time, this material is very strong, compressive strength is 0.12–0.22 MPa. This insulation material saves on energy resources, as it has low thermal conductivity.

The well-thought-out shape of the slabs and a special joint edge reliably protect the room from drafts. Due to this, it is possible to achieve a continuous thermal insulation contour, which is impervious to cold.

Advantages and disadvantages

Penoplex "Osnova" has several important advantages.

- This material is a good heat insulator, this is achieved due to the structure in the form of cells. Penoplex can be used even in a harsh climate.

- Penoplex is resistant to evaporation, that is, vapor permeability is at a low level.

- The material is moisture resistant. In this regard, it can be used to insulate baths or saunas.

- It is highly durable. This material is able to withstand significant loads, and therefore it is distinguished by its durability. It will be able to serve for about 50 years, while retaining its original properties.

- Penoplex is safe and environmentally friendly.

- This insulation is easy to install, it can even be easily cut with a knife. And also the installation of insulation is possible in any weather.

- It is lightweight.

- The material provides good sound insulation.

Penoplex "Osnova" also has some disadvantages, namely:

- this material is obtained artificially, it is unnatural;

- quite expensive material;

- emits a lot of smoke when ignited.

Usage

For floor insulation

When insulating the floor with penoplex, the following steps must be taken:

- replace all faulty boards;

- soak all wooden elements with antiseptics to prevent rotting;

- all defects in the form of cracks or grooves must be eliminated with a special putty;

- it is necessary to process the surface with a primer;

- when the primer is completely dry, proceed directly to the installation of foam sheets;

- by cutting, the sheets are adjusted to the required dimensions and placed on prepared boards;

- during installation, carefully monitor that the joints between the foam boards are minimal;

- special construction tape is used to fix the plates to each other;

- on sheets of foam, if necessary, lay the material for vapor barrier. A layer of plywood or planks is applied to this layer.

For floor insulation when installing on the ground

Installation of insulation material on the ground is carried out if the house has a pile or strip foundation. This process includes the following steps:

- first of all, they level and tamp the ground;

- a layer of crushed stone and gravel is poured onto the surface of the earth, and then a layer of sand follows, which is carefully tamped;

- on the resulting "pillow" begin to install sheets of foam;

- waterproofing material is laid on sheets of insulation material, which is necessary to protect against moisture penetration;

- the structure is reinforced by reinforcement with a metal mesh;

- the resulting structure is poured over the mesh with a special cement mixture;

- at the very end, laminate, linoleum or parquet is laid on the frozen layer.

For internal wall insulation

In the recent past, in most cases, foam was used for internal wall insulation. Now, with the invention of foam, they began to use it for these purposes, since its characteristics exceed those of foam. Before you start working on wall insulation, you need to know how this process takes place.

Penoplex insulation includes several stages.

- First of all, you need to prepare the surface to be treated. The facing materials are being dismantled. Then the surface is subjected to leveling and elimination of defects, plastering of dents and irregularities is performed.

- In order to improve the process of adhesion of the treated surface with the insulation material, a layer of primer is applied.

- Penoplex does not allow moisture to pass through, but in some cases they create a layer of waterproofing.

- The process of attaching an insulating material to the surface to be treated. Fastening is carried out using dowels, but you can use special glue for this purpose.

In most cases, both dowels and adhesive are used for reliability. They are applied immediately to two processed planes, both on the surface of the wall and on the penoplex.

- When the process of fixing the foam is completed, it is necessary to check all the joints, since cold air can penetrate into the room through such gaps. If there are such problem areas, they are filled with sealant. It is also necessary to check the most problematic places - these are those where the insulation is adjacent to windows or doorways.

- Penoplex is a material that does not allow moisture to pass through, but it is still necessary to fix the film for vapor barrier. It is used to prevent moisture from getting into the joints between different sheets of foam.

- Start finishing work. In most cases, a reinforcing mesh is mounted on a layer of insulation material. Align the applied special glue. Then the wall is finished with facing material.

- For the convenience and simplification of the installation of the finishing material, first fix the plasterboard sheets, which are the basis for working on the wall decoration.

For pitched roofs

Penoplex "Osnova" can also be used as an insulation material for a mansard-type roof. The process of installing insulation is carried out in the same way as in the cases discussed above. The foam is laid between the rafters. Special nails or glue are used as fasteners.

Thickness calculation process

To obtain the desired result in warming the room and creating the most comfortable conditions in the house, it is necessary to carefully choose the insulation material. An important characteristic is the thickness of the foam sheets. The choice of the thickness of the insulation is influenced by the materials from which the house is built (their thermal conductivity). And also the indicator of the average temperature in the winter season.

Penoplex sheet thickness of 30 mm is selected if the building is located in the southern region. If the climate is moderately continental, then choose a thickness of 50 mm. If the climate in the region is sharply continental, then the thickness should be from 100 mm.

How to choose?

When choosing an insulating material, one should not forget about the recommendations indicated by the manufacturer of the material. When the material is selected and it is to be purchased, you should familiarize yourself with the certificate of conformity of the goodsto avoid acquiring a fake. It should be noted that the choice of Penoplex "Osnova" as a warming base is a profitable purchase.

You can install the insulation on your own, without resorting to the help of specialists, since the Penoplex "Osnova" has special joining edges, which makes the work easier.

It provides great savings in additional material, for example, you do not need to spend money on purchasing a waterproofing layer, since penoplex does not absorb water. With its help, you can save on heating the room, as it is characterized by reliable thermal protection.

See the next video for the technology of foam insulation of the loggia.

The comment was sent successfully.