"Penoplex 45": technical characteristics of the material

The walls and foundation of each house must be additionally insulated so that you can live comfortably inside at any time of the year. The modern construction market does not stand still and every year produces more and more new materials for work. One of them is the Penoplex 45 insulation.

This material is a conventional extruded polystyrene foam. In this article we will consider the features and advantages of "Penoplex 45", its technical characteristics and scope.

Features and Benefits

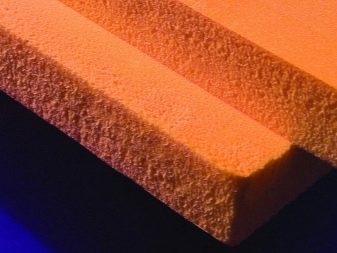

The first extrusion machine appeared in the USA in the middle of the last century. During the production of the material, high pressure and temperature act on the polystyrene half-cylinders. The process is accelerated by a special foaming agent consisting of carbon dioxide and light freon. The final mixture looks more like whipped cream, it is she who passes through the extrusion apparatus, as a result of which the resulting mass becomes finely porous.

Each ball measuring 0.1-0.2 millimeters is isolated from the rest. Their uniform arrangement provides an increased density of the final block, which has many advantages.

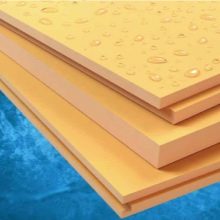

- One of the main advantages is the almost complete moisture resistance of the product. Like all new products, Penoplex 45 was tested before being put into operation. The creators carried out the following experiment: the blocks were completely immersed in water for a month. Only very little water was absorbed, and then only the first nine days, the subsequent period, the plates no longer absorbed moisture. At the end of the experiment, it turned out that water could only penetrate into the outer walls of the material, while the inner ones remained intact.

- The next advantage of the product is the low level of thermal conductivity., especially in comparison with other heat insulators. Its value is 0.03 W / mK. Thanks to the previous point, foam blocks can also be installed in places with high humidity, while the level of its thermal conductivity remains practically in place, it can vary between 0.01-0.03 W / mK. That is why the materials are recommended for insulating roofs, attics and even foundations without installing an additional protective layer.

- Reduced vapor permeability of foam - another plus of the material, which, along with others, ensures its long service life. The extruded polystyrene foam was repeatedly frozen and then allowed to thaw, while each time its characteristics were measured, which remained unchanged. Thus, the researchers came to the conclusion that the foam blocks will last more than fifty years, taking into account all atmospheric changes.

- Even distribution of balls inside the slabs and structural homogeneity provide increased strength of the material, so the penoplex does not deform even under heavy load. Due to its low weight, "Penoplex 45" is easy to install, it can be quickly laid along the walls, and such work can be done even by beginners in the repair business. The blocks are easy to cut with an ordinary knife, they do not need a certain level of humidity or temperature, they are mounted even in bad weather. Foam blocks are completely environmentally friendly, their production does not harm the environment, and the freons included in the composition are not subject to fire, do not have a toxic odor and do not destroy the ozone layer.

- Among the advantages of the material, biostability is also indicated., thanks to which the appearance of mold or mildew is prevented. It is also inedible for rodents and insects. Foam blocks are not affected by any chemicals used in repair or construction work.

No acid, alkali, salt, water or paint can damage the boards. Butane, ammonia, any kind of oil or paraffin also cannot harm this product. Such substances include freons and cement mortars.

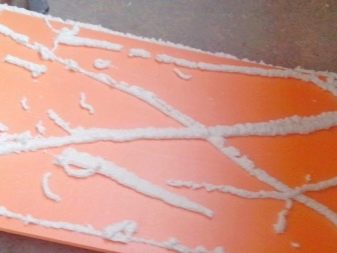

However, there are still some types of materials that can adversely affect Penoplex, deform it or even dissolve it. These include the following: formalin, acetone, gasoline or kerosene, any ether mixtures and polyesters, as well as coal tar and oil paints.

The only drawback of expanded polystyrene is its quick flammability, which at a certain temperature can harm the plates. Therefore, it is recommended to lay them, focusing on the temperature indicated in the insulation passport.

Applications

Penoplex 45 has a fairly affordable price, which, together with good technical data, allowed it to receive increased demand in the construction market. The cost of the material is just over 3200 rubles.

The blocks have a fairly wide range of applications.

- Plates can be used to insulate basements, house foundations, basements, floors and walls in various premises (residential or public).

- The products are used to insulate streets, sports grounds, parking lots, as well as pedestrian zones.

- Highways and airport runways also need thermal insulation, so Penoplex 45 is also used in these cases, since the increased strength and wear resistance of the material guarantee a long service life. In addition to strength, foam blocks give roads and protection against cracking after severe frosts. If the tracks are built of a special kind of soil that is not moisture resistant, they can swell after rain, snow or hail. Insulation will help prevent such a case and prevent the roads from freezing.

- In addition to insulation, "Penoplex 45" also performs stabilization, vibration damping with frequent dynamic surface loading. Their strength allows them to withstand about fifty tons of weight per 1 m2 and evenly distribute the force of gravity over the entire base. The availability of such material is very important for better road safety and safety.

- "Penoplex 45" in some cases also becomes an auxiliary element of load-bearing walls. In this case, it not only insulates, but also strengthens the structure, giving it additional reliability.

Specifications

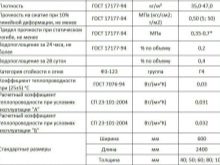

The density of products is 35-46 kilograms per 1 m3. Foam blocks absorb 0.4% of their volume of water within a month. The allowed temperature for using the penoplex varies from -45 to +70 degrees. Plates belong to the fourth category of combustion "G4", which indicates their easy flammability.

The length of all blocks is standard - 240 centimeters, width - 60, but the thickness varies depending on the model, it can be 40, 50, 60, 80 and 100 centimeters. Materials with other dimensions can be made to order. When laying insulation, there is no need to be guided by the weather, but it is imperative to protect it from sunlight, as the rays harm the top layer of the products.

Upon completion of the installation, it is recommended to cover the penoplex with a protective material in order to protect it from adverse weather conditions. The same should be done for outdoor storage.

Professional advice

When laying the segments and half-cylinders "Penoplex 45", a special adhesive is used. To begin with, you should thoroughly clean the surface of dust and dirt, prime the cracks and eliminate irregularities.Then glue is applied to the board and it is pressed firmly against the wall. In some cases, the insulation is additionally fixed with metal or plastic dowels. The first option is used when working with the outer walls of the building, the second - when insulation occurs inside.

Dowels allow you to achieve a higher installation density, however, they break the tightness of the sheets. Another reliable fastener that increases the quality of styling the foam is self-tapping screws, which also negatively affect the tightness of the products.

When choosing an adhesive, one should proceed from the type of finishing work and the type of room. For example, when laying in a room with a high humidity level, it is recommended to buy a polyurethane adhesive. You should also focus on the material of the treated surface. Before buying, be sure to read the instructions and technical characteristics of the mixture and correlate them with the properties of Penoplex, if they are compatible, you can safely take the mixture.

In any hardware store, you can contact a consultant who will give professional advice and help you make the right choice.

It is necessary to pay attention to the composition of the glue. Among its ingredients, in no case should there be substances that destroy the surface of the foam block. First of all, these are gasoline, acetone, ether and kerosene. Other inappropriate materials are listed above.

Reviews

Reviews about Penoplex 45 are mostly positive. Buyers are satisfied with the reliability of the product, its durability, environmental friendliness, durability and high quality. Allergy sufferers, who were afraid to endanger their health, also left their opinions, but all their fears turned out to be unfounded. Foam blocks are absolutely safe for health. Almost every review says that "Penoplex 45" helps to save a lot on heating at home.

In the video below, see the technology of insulating the loggia with penoplex.

The comment was sent successfully.