"Penoplex" 100 mm: types and characteristics of insulation

When building a dwelling, it is better to take care of preserving heat in it in advance. This can be done with the help of building insulation materials. One of the most modern and widely used insulation materials is "Penoplex" 100 mm.

Properties

"Penoplex" 100 mm is a plate of extruded polystyrene foam with a thickness of 100 mm. For the manufacture of insulation, the technology of mixing polystyrene grains of sand in an extruder is used, where a means for foaming is supplied under pressure. From the resulting slurry, sheets are formed, which, when cooled, are formed into finished slabs. The sheet can be easily resized by cutting the material.

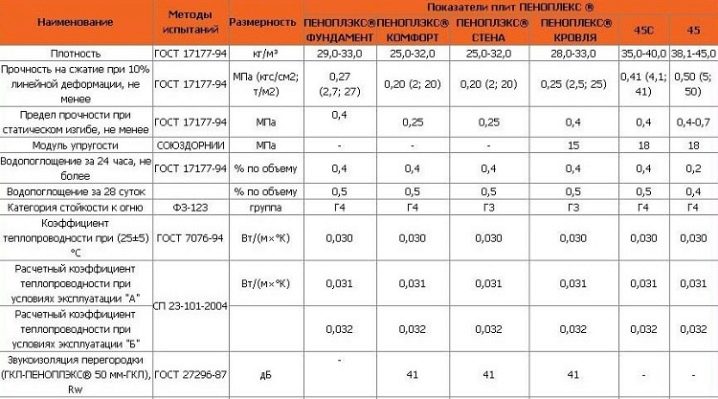

The main characteristics include several indicators.

- Strength. This property is very important when insulating structures that are under constant pressure, for example, floors, foundations. The insulation can withstand a load of 20 tons.

- Moisture resistance.

- Long service life. High-quality insulation can retain its original properties for 50 years.

- Refractoriness.

- Environmental friendliness. Polystyrene is composed of carbon and hydrogen particles.

- Suitable for use over a wide temperature range. The operation of polystyrene is carried out at a thermometer reading from minus 50 degrees to plus 50 degrees and above.

- High thermal protection.

- Resistance to ammonia, alcohol, alkali, chlorine, various acids.

- Ease of use.

Application

Plates with a thickness of 100 mm are used in the construction of private houses or industrial structures.

With the help of polystyrene they insulate:

- walls;

- ceilings;

- floor;

- foundation;

- roof;

- basement rooms;

- roads, tracks, runways - the insulation prevents swelling, cracking of the surface when exposed to low temperatures;

- any pipelines;

- sewer pipes.

"Panoplex" is often used to insulate balconies, saunas, baths, facade structures.

Insulation works can be carried out at the stage of construction, repair, reconstruction. Due to the unique properties, as well as the relatively low price, the scope of application of this insulation is huge. Prevention of surface freezing and moisture accumulation allows maintaining many life support systems in working order in any weather. To obtain a high-quality result, the type of insulation corresponding to the type of work is selected.

Views

Among the most common varieties of Penoplex insulation with a thickness of 100 mm, the area of which is 2.773 m2 in a package, there are several that are most in demand.

- "Geo". Plates have a flat smooth orange surface. They are used in the construction of residential or industrial facilities. With the help of this type of insulation, thermal insulation of structures is produced on which constant pressure will be exerted, for example, a foundation or a floor. The material is distinguished by increased strength properties, but has poor fire resistance.

- "Roof". Plates have a flat smooth orange surface. The material contains additional refractory components. It is used for any kind of roof insulation.

- "The foundation". Plates have a flat smooth orange surface. It is used for insulation of any standard structures, for example, floors, walls or roofs, where there are no requirements for increased material strength.

- "Facade". Plates have a milled orange surface. Refractory components are also included. This material is used to insulate partitions, facade structures.

Terms of use

When carrying out work on insulation, it is necessary to follow a certain sequence of actions.

- The base is prepared by cleaning it from dirt. If there are roughness on the surface, then it is recommended to level them with plaster. Before using the insulation, the base can be treated with a composition that prevents the appearance of fungal infection. After complete drying of the treated surface, they begin to warm.

- Polystyrene boards are glued with a special glue. In this case, the adhesive is applied directly to the surface of the board.

- Then mechanical fixation is carried out using dowels.

- After that, the slabs are covered with plaster in several layers. But wood and drywall can also be used. When carrying out insulation work, it is recommended to apply polyethylene before fixing drywall. This provides the best vapor barrier.

It should be noted that when using drywall as a finish, it is better to give preference to moisture resistant types.

To increase adhesion when finishing with plaster, the outer side of the polystyrene boards is roughened.

Selection Tips

When choosing a heater, it is necessary to pay attention to the thermal conductivity index. Not only the amount of material required for insulation depends on this, but also the degree of moisture resistance. The higher the coefficient, the worse the protective properties, the more insulation you need.

It should be noted that high thermal insulation prevents the possibility of deformation of the insulation boards in the vertical position.

The surface structure of polystyrene boards must be firm and even. Otherwise, there is a danger of moisture accumulation, which in the future can lead to the appearance of dangerous microorganisms that not only destroy the material itself, but also harm health. The material can be tested by immersing it in water for several weeks.

A high-quality composition is characterized by the absence of crumbs or the ability to change shape during insulation work.

When choosing a heater, you should check the evenness of the edges. A surface can be tested by clicking on its base. In case of a slip, it is better to refuse such a heater.

The result of insulation depends on the correctly selected type of insulation and its performance.

You can learn how to insulate walls with Penoplex with your own hands by watching the video below.

The comment was sent successfully.