Features of polytherm insulation

Nowadays, there are many types of insulation. Each buyer can choose the best option for any operating conditions. A modern insulating material called "Polytherm"... In this article, we will find out what its main features are.

Characteristics and properties

Today, polytherm has become a very popular insulation, which is in great demand. This material looks like a tape coating of a characteristic golden color.

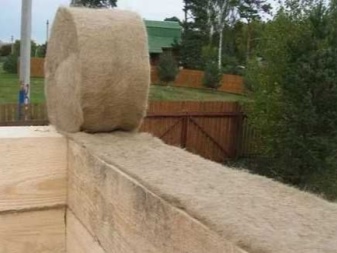

It is due to this color that polytherm is so well combined with natural wood and is often used in construction as an inter-row seal.

The insulating material in question is made from specialized polyester fiber in accordance with a special technology... The latter implies thermal bonding, which is done under the influence of very high temperature indicators.

First, the fibers of the raw material are thoroughly combed, after which they are mixed on special plucking and carding units in several steps. As a result, the mixture of fibrous type acquires the appropriate structure.

After that, the material is sent to the next production stage for aerodynamic shaping of the product. At this time, the fibers are distributed both along and across. Thermal bonding takes place in a special oven. Here, other indicators of the material are controlled, for example, its thickness.

Let's analyze the main technical characteristics of the polytherm.

- Thermal conductivity. This coefficient for the material under consideration is 0.033 W / (m2 * K). Due to this, the polytherm can be laid out in 1 layer in order to obtain good thermal insulation and completely block the access of cold air to the existing cracks.

- Moisture resistance... Polytherm has a hygroscopicity index of 0.78. The material cannot absorb water from the surrounding atmosphere, even if the humidity level is 100%.

- Vapor permeability... Polytherm is good for air permeability. At the same time, the insulation is practically not moistened, and also does not allow condensation to accumulate on the walls.

- Fire safety... If polytherm has not undergone special treatment with antiprene compounds, then it can only begin to melt, without flashing and without releasing harmful substances into the air. If the insulation nevertheless passed the appropriate processing at the production stage, then the level of its fire resistance increases significantly, due to which the polytherm does not burn at all.

- Sound insulation. Polytherm is often used as an intervening material. It absorbs all unnecessary sounds and noises very effectively. According to this parameter, the material is effective in the same way as a jute thermal insulator.

- Biological stability. Polytherm is not attractive to birds, so they do not undertake to tear it into separate pieces in order to subsequently build nests from them. In addition, in the considered insulation material, various insects or microscopic organisms usually do not start.

- Chemical resistance... Polyterm never participates in reactions with various building mixtures and solutions, gasoline, alkalis or acids.

- Environmental Safety. As part of the polytherm, there are no dangerous phenol-formaldehyde resins that can cause serious harm to living organisms.There are no other toxic substances in the material either. It is allowed to work with it without the use of additional protective devices. Over time, polytherm does not begin to decompose and does not emit various kinds of volatile compounds into the surrounding atmosphere.

- Terms of operation. Unlike other existing heaters, which differ in a relatively short service life, Polytherm is capable of not losing its positive characteristics for at least 100 years. If necessary, this material can be reused.

Polytherm is a hypoallergenic material. When it is laid, it does not create a lot of unnecessary dust. The fibers in the insulation are not too small to easily penetrate the respiratory systems, so you can interact with it without a respirator. Polytherm does not emit unpleasant chemical odors, so there will definitely not be headaches after laying it.

Species overview

Modern insulation material is often produced in the form of a tape. This form is explained by the fact that polytherm is used as a mezhventsovy heater most often. However, it is possible to find products in stoves in stores. It is the ideal solution for insulating wall bases, attics, roofs or attics.

Polytherm in ribbons is subdivided into the following subtypes.

- Standard... The tape of this category has a thickness of 15 mm. Ideal for mounting between round logs. The density of the polytherm standard can reach 300 g per cubic meter. The thickness varies from 100 to 250 mm. The option with a certain thickness should be selected based on the diameter of the log.

- Super... This is a 22 mm tape. This insulation is sold in rollers of 10 rm. Perfect for manual felling logs with a fold. It can also be laid under the starter crown.

- Light... This insulation has a thickness parameter ranging from 8 to 10 mm. Usually it is bought for profiled or glued beams. The density of polytherm light is 170 g per cubic meter. The material width indicator is also selected in accordance with the dimensions of the bars - from 100 to 250 mm.

- Economy... The tape of the named class has a thickness of 20 mm. Perfect for high-quality insulation of buildings made of rounded logs. The density of the materials under consideration reaches 200 g per cubic meter. The usual belt width is 100-250 mm.

Polyterm can also be classified according to the presence or absence of additional filler substances that improve certain technical parameters of the material.

Popular manufacturers

Today, the insulating material in question is made by different manufacturers.

On sale, buyers can find quality products from both large and little-known firms.

Let's get acquainted with some of them.

- Eco Heaters Center. A manufacturer that produces many different mezhventsovy heaters of good quality. The assortment of the company includes products on a synthetic basis.

- "Termopol". A Moscow company specializing in the manufacture and sale of high-quality synthetic insulation materials containing polyester and polyester fibers. Polytherm is also found in a wide range of products.

- "Winter House". A brand that supplies polytherm to the market not only in the form of rolls, but also in the form of plates. The materials are suitable both for insulating gaps between crowns and for various kinds of horizontal and vertical surfaces.

Comparison with other materials

Many consumers are interested in how polytherm differs from other popular heaters. This question is especially acute when it comes to cheap jute or flax.

It should be noted here that it makes no sense to compare polytherm with flax, since the latter is used extremely rarely today (this technology has long been outdated).

Let's consider a more detailed comparison of polytherm and jute.

- Polytherm does not need caulking after laying, which cannot be said about jute. Caulking for jute is necessary, otherwise noticeable gaps will soon form between the logs.

- Recovery after full compression is 0% for jute and 90% for the material in question.

- Jute absorbs moisture by 25-27%, and high-quality polytherm does not absorb it at all.

- If it gets wet, the jute begins to rot and in just a few months it completely decays. The insulation under consideration does not have such problems.

- Jute lacks vapor permeability, while polytherm has quite high vapor permeability.

- You cannot reuse jute, but the insulation in question is possible.

- On average, jute can last 1-2 years. Polyterm, on the other hand, under the correct operating conditions, can serve for about 100 years.

Judging by the listed differences, polytherm is better than cheap jute. That is why it costs much more.

Selection Tips

Polytherm, like any other insulation, must be chosen correctly. Let's take a look at what criteria a buyer should pay attention to when he wants to purchase this material.

- We need to look at the color of the material. A high-quality polytherm will have colors ranging from sandy to dark yellow. Such scales resonate well with natural wood.

- No nauseating chemical smell should come from the insulation. If traders justify this by the presence of additional additives in the content of the product that improve its properties, then it is worth asking what kind of compounds and components are we talking about. The insulation should not contain formaldehyde.

- The insulation product must have a uniform density. Throughout its entire length, the tape should have an equal measure of width.

- If the material is selected for a harsh climate, then the thickness of the insulating layer should be high enough.

- It is recommended to find a tape, the width of which is slightly larger than the width of the logs, from which the house or other structure will be erected. Even a small margin will allow you not to encounter gaps, which often appear due to the shrinkage of the structure.

- It is best to choose such an insulating material that was released by a well-known brand. Branded products are always of higher quality, although they are often relatively inexpensive. Original products from well-known manufacturers can be found in specialized stores selling insulation, building and finishing materials.

Installation rules

Let's analyze the main features and rules for installing a polytherm.

- Material of suitable width must be spread over the timber or along the grooves between the crown that are between the logs.

- Further, the material must be carefully fixed on the elements of the beam, using a stapler or small nails.

- Then you need to lay out the next log or timber in the constructed frame. In this case, the tape of the insulating material must be pressed down as tightly as possible - do not forget about this.

- The next step is to carefully cut off the remnants of the insulating material after completing the assembly and laying of the log house.

- All protruding sections of the polytherm should be carefully caulked.

Self-assembly of the polytherm is not difficult. All procedures take very little time.

The comment was sent successfully.