Styrofoam houses

Styrofoam houses are not the most common thing. However, by carefully studying the description of domed houses made of foam blocks and concrete in Japan, you can understand how good such a solution can turn out to be. And of course, it is very important to figure out how to build a Japanese frame house with your own hands.

What it is?

Even 20-40 years ago, the very phrase house made of polystyrene sounded ridiculous, and even the most loving new technologies people did not suspect that this was possible. However, over the past couple of decades, engineering developments have made such structures a feasible alternative to established building structures on the market. Of course, structures are not created from simple ones, but from reinforced polystyrene foam, which holds loads much better. Reinforcement made of high-quality steel is inserted inside the blocks and then concrete is poured. This technique allows us to guarantee very high durability and reliability of products.

In addition, excellent insulation is initially provided. Styrofoam building blocks can be made in different types and sizes. At the final stage, the walls are plastered or covered with another cladding. In Japan, building foam houses is very common. For this purpose, practical islanders take extruded material, the density of which reaches 30 kg per 1 m3.

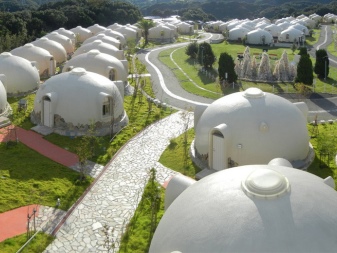

The Japan Dome House Co company builds round, more precisely, made in the form of a sphere or dome of the house. All of them are 1 floor high. The special processing of the foam ensures very high strength. There is no need to talk about classical construction; rather, the process resembles an assembly from blocks. This significantly speeds up the work and makes them cheaper.

The walls of styrofoam houses are relatively thin. But this does not prevent them from fulfilling their main task. The methodology for performing work in Japanese conditions has been debugged down to the smallest detail. Therefore, the likelihood of errors is minimized. There are many finishing options, and the technology itself is already widely used both in Russia and in European countries.

Advantages and disadvantages

Styrofoam houses in our country remain warm even in the most difficult regions. That's why their use is justified no less than in foreign Asia or Western Europe. Expanded polystyrene is superior to most other insulation materials. Reducing wall thickness (also due to the minimal need for additional thermal insulation) will be a very attractive feature. Among the pluses, the ease of the created structures can also be named.

This minimizes pressure on the foundation and on the substrate under the house. Expanded polystyrene lasts a long time. If all production and construction and installation operations are performed correctly, you can expect to operate for at least 30 years. In addition, various dangerous fungi and other pathological organisms do not start in the foam layer. However, there are also serious disadvantages:

-

polystyrene is fire hazardous, and emits toxic smoke when burned;

-

creation of a vapor barrier;

-

despite good sound insulation, this material is hygroscopic;

-

on contact with solvents, EPS is destroyed, and very quickly;

-

this material cannot be strong enough without considering additional reinforcement.

It is worth considering separately that we are talking about spherical houses. Such structures also have strengths and weaknesses.

The developers from Dome House themselves have already noticed this. In our country, there are still no standards and building codes for such structures made of expanded polystyrene. And each developer applies the independently developed technical conditions.

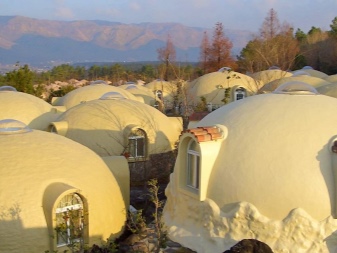

Dome structures save heat better and are very lightweight. Even more than traditional building shapes, they save on foundations. You just need to take into account that ultimately the price, and the complexity of construction, is determined by the thickness of the walls and other practical characteristics. In any case, in comparison with structures comparable in terms of consumer parameters, dome-foam assemblies are very profitable. The shape of the dome allows the house to successfully withstand the effects of snow and wind. True, there are weaknesses:

-

extreme complexity of independent calculations;

-

lack of experience with such buildings in most organizations;

-

lack of long-term experience of use;

-

a very specific layout of the dwelling;

-

the need to make custom-made windows and doors;

-

the inability to use many materials for decoration.

How are domed houses built?

It should be said right away that building a house from foam blocks using Japanese technology will not be as simple and cheap as it seems to non-professionals. The absence of special standards makes it necessary to focus on:

-

SNiP 23-02-2003 "Thermal protection of buildings";

-

SP 23-101-2004 "Design of thermal protection of buildings";

-

GOST R 54851—2011 “Non-uniform enclosing structures. Calculation of the reduced resistance to heat transfer ";

-

the main climatic parameters of the region.

But it is important to understand that all these standards and the calculations based on them are correct only for walls made of rectangular elements - both with concrete and frame type, and at the same time with traditional general geometry.

Even for professionals, it is not so easy to figure out how to transfer the methods worked out in construction from panels to the construction of domed foam houses. The more mistakes are made by those who try to build such objects with their own hands. Previously, we can say (with large estimates and reservations, for the middle band) that the combination of 140 mm walls with a 30 mm layer of plaster will allow you to live comfortably and save on heating without inconvenience.

The total cost of a relatively small dome (at the stage of factory production, excluding shipping and installation) will be at least 200 thousand rubles. House kits are usually made in 3-7 days, depending on the size and technological complexity. The assembly of house kits is carried out using polyurethane foam glue. For such work, lasting about 1-3 days, builders can take at least 50-70 thousand rubles. That is, if, again, everything goes perfectly.

But it is still impossible to stop at this stage. You will definitely need to apply plaster. Without it, the foam will not be sufficiently protected from weather influences and mechanical destruction. Plastering is carried out using mechanized devices. Usually the rate for such works starts from 600 rubles per 1 sq. m, but can grow.

Taking into account the delivery of materials and the execution of the work itself, the procedure takes from 24 to 48 hours. If we take the inner surface area equal to 90-100 sq. m, then plastering it will cost 54-60 thousand rubles, respectively, at least.

With a smaller size of internal structures, it makes no sense at all to contact the domed house made of foam. Then he will not be able to reveal all his advantages.

Dome houses with a door and three windows at the stage of rough finishing will cost 360-420 thousand rubles. This amount does not include the foundation, geological exploration, paperwork and permits. True, the foundation can be made as simple as possible due to the lightness of the load. Often they dispense with a pile-screw base.But even this simple support can be built in different ways, with different costs, so no one will give universal numbers here.

Nevertheless, even the minimum approximate figures will give about 500 thousand rubles for 48-52 sq. m area. This is the cost excluding windows and doors, internal partitions and engineering systems.

All additional structures will also have to be installed. The final calculation, as in the case of traditional houses, is carried out on the basis of a design project. Without drawing it up, there is very little chance of success.

Assembling from ready-made assemblies in any case simplifies the matter. Japanese developers suggest that such buildings can be built even on difficult terrain. The slopes of the terrain and the fluidity of the soil will not become an obstacle either. The most expedient in such cases is the use of an annular shallow foundation. However, the classic version of the work is the construction of a domed dwelling on rocky or swampy areas without modifications to the walls and geometry of the buildings.

When the base is equipped, the installation of the walls begins. Simultaneously with them, the middle fixing ring is placed, which turns into the power part of the structure. As in ordinary houses, they lay the floor, put windows and doors, paint the walls, and stretch channels with wires. According to the Japanese builders, after plastering the outer walls, it is necessary to also apply polyurethane foam resin.

On request, the construction of a boathouse is allowed. It has an increased usable area with the same wall loading. But more often, foam shedding houses are not needed for housing, but for warehouse or office needs. It is also possible to add a second floor, and to install ceilings, decorative walls. But all such solutions significantly increase the cost of work and complicate them, including the need to rework standard projects.

True, they are resorted to more and more often. The reason is simple - the enhancements allow you to enjoy the comfort of city life. The European version of the domed house can be built not from simple EPS, but from polystyrene concrete. The increase in strength is accompanied by an increase in the mass of the structure, and with this approach, one can no longer do without shallow foundations and high-quality drainage. As you can see, foam houses can be made in a variety of ways and deserve close attention from developers.

The comment was sent successfully.