House from OSB panels

OSB panels are a modern and practical material from which you can build a huge number of different buildings. Today, houses built from similar elements are increasingly common. In this article, we will find out what the advantages and disadvantages of such structures are and how they need to be built correctly.

Advantages and disadvantages

Today, new building materials are constantly on sale, suitable for the construction of various structures. These can be outbuildings or entire residential buildings. So, at present, OSB panels are very popular, from which very good dwellings are obtained. Many users decide to build a house from these building materials.

The demand and widespread use of houses built from OSB panels is due to the many advantages that are characteristic of them.

Let's find out what exactly are the main advantages of such constructions.

- One of the most serious advantages is the absence of the need to use specialized heavy equipment designed to lift and move large loads. OSB panels are not so massive and heavy, so it is very easy to build any structures from them.

- Today frame houses are popular and in demand. These are modern and very practical dwellings. Such buildings using OSB-plates can boast of fire safety. They are fire resistant, especially in comparison with classic log or timber buildings.

- The materials in question are often used as cladding panels. They make a practical, moisture-resistant cladding, for which there is no need to build a strong and expensive foundation.

- When a residential building is built from OSB panels, lightweight and durable roofing materials are usually used for it, which are highly resistant to moisture. This simplifies roof insulation.

- A complete set of frame house made of OSB panels can easily fit into several heavy vehicles.

- The residential buildings in question are much cheaper than their stone or brick counterparts.

- A house from the panels under consideration can have absolutely any layout and style of decoration - the owners are not limited in anything.

- It is not necessary to build a solid recessed foundation for a frame house from OSB panels. This is due to the fact that such structures are of modest weight.

- The decoration of such houses turns out to be simpler and faster. The fact is that OSB panels are perfectly smooth and even, so unnecessary manipulations for leveling and preparing the bases are not needed here.

- The panels are flexible to work with. They are easy to saw. The necessary holes are drilled into them without any problems.

Modern residential buildings made of OSB panels have their drawbacks. Here are the most serious ones.

- Buildings made from such panels are less durable than brick or block ones. But this does not mean that the house from OSB sheets will definitely not last long. With proper execution and care, such erections can stand for more than half a century.

- Any stone materials are stronger and stronger than OSB slabs.

It is worth giving preference to this material only after evaluating all its pros and cons.

Choice of slabs

For the construction of a residential building, you need to choose the right OSB slabs. They are divided into several categories, each of which is suitable for specific operating conditions.

- OSB-1. We are talking about a building material that is poorly resistant to moisture and moisture, as well as heavy loads. It is usually used for the manufacture of furniture structures.

- OSB-2. Slightly more durable material. Suitable for use in places where there are no too heavy loads and the risk of getting wet. Often OSB-2 is used for the construction of partitions or decorative ceiling bases, which are not structural components of the building.

- OSB-3. These panels are used to make strong load-bearing structures that are used in high humidity conditions.

- OSB-4. Specialized material with increased strength. Even without additional protective treatments, OSB-4 can withstand high levels of humidity for a very long time.

Houses are most often built from OSB-3 sheets. Such materials are perfect for the construction of both residential and office buildings.

Design

It does not matter what kind of house you want to build - summer, country house, two-story or one-story. In any case, you will first need to draw up a detailed project for the future construction. You can independently undertake such operations if you have already encountered similar cases and have the appropriate knowledge / skills. If there are none, then it makes sense to contact specialists or use ready-made plans.

Let's consider some options for drawings.

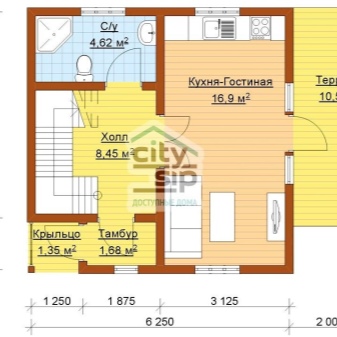

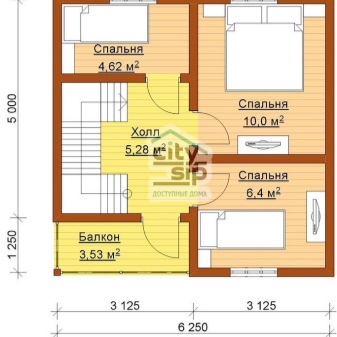

- You can build a very cozy house in which there are 3 bedrooms on the second floor with an area of 10 sq. m, 6.4 sq. m and 4.62 sq. m. Between them, you can equip a hall of 5.28 sq. m, and put a staircase in the hall from the first floor. On the 1st floor there is a place for a large kitchen-living room of 16.9 sq. m, bathroom - 4.62 sq. m, hall - 8.45 sq. m. Also below you can equip a porch, vestibule and terrace.

- From OSB sheets, you can build a spacious two-story house with a gable roof and a roof of a contrasting dark shade. The structure can have a standard angular structure of a rectangular or square shape. In the building, as in the photo, you can equip all the necessary rooms, and then install an addition in the form of a terrace.

- If desired, from OSB panels, you can build a cozy mini-house or a panel cottage of a small square... Such a structure will be the best solution for a plot of a modest area. Small houses made from these building materials can look very attractive and well-kept, but they are not too expensive.

Construction stages

If the plan for the future construction is ready, and all materials have been purchased, you can start construction work. Let's figure out how to properly build a house from OSB panels.

Laying the foundation

First you need to prepare the foundation. This can be easily done by hand. In this case, columnar or tape options are most suitable.

So, the pillars must be placed in the corners of the future house and at the joints of partitions with load-bearing wall bases. The rest are set at a distance of 1.5 m from each other. The pillars must be dug in to a depth below the freezing point of the soil. Fix them with a concrete base.

The pillars should rise above the ground by at least half a meter. Such solutions are ideal for areas where there is no severe frost, otherwise it will be very difficult to heat the house.

Frame construction

When the foundation is ready, you can build the frame base of the house. Let's analyze the step-by-step instructions.

- On the finished foundation, I expose the lower strapping from the bars. Fasteners need to be made on the anchor bolts.

- A waterproofing layer must be placed between the tree and the foundation.

- The surface must be strictly horizontal so that there are no distortions. Having installed the frame supports, the upper harness is laid on them and vertical support boards are exposed. It is to them that the panels will be attached. Their length should correspond to the height of the ceiling.

Walls

If OSB-3 or OSB-4 panels will be used for the construction of walls, then you need to use a heater that will not be needed for sandwich panels, since they already have it. No waterproofing is required either.

In order not to encounter distortions, you need to put braces. They are installed after laying the insulation. It is advisable not to use metal fasteners, since OSB panels often begin to rot from contact with them.

It is at this stage that the interior partitions are mounted. They can be made from OSB-2 sheets.

Floor

In a house made of OSB panels, the floor is laid in 2 stages. First you need to prepare the base, which is attached to the foundation. This base is usually made from untreated boards with waterproofing, log and insulation between them. Everything is mounted in such a way as to indicate the location of the internal partitions. Then the next layer of OSB boards is laid. They are laid out perpendicular to the base elements.

If linoleum, parquet or ceramic tiles will be laid on the floor, then it is better to install plates with a thickness of at least 10 mm. They must be installed with a double layer.

Roof

The final stage is the construction of a gable roof. It is necessary to make a continuous crate.

For this OSB sheets are laid out in such a way that the joints are exactly above the rafter joists. Next, waterproofing is laid, and tiles, ondulin or other material are mounted on top of it. Insulation and vapor barrier are laid on the underside.

Finishing

After all the necessary foundations of the house from OSB panels are ready, you can proceed to finishing the resulting building. Both the external and internal design of the residential construction must be performed correctly. We will learn about the features of finishing houses from OSB panels.

External

The outer surfaces of modern houses made of OSB boards are usually finished with traditional materials, which are often used in the construction of other buildings. PVC panels, high-quality clinker tiles or siding are ideal for this.

Since during the assembly of the walls of the dwellings in question, it is necessary to leave the so-called expansion gaps, then before starting the external finishing work, they must not be forgotten to fill with a special acrylic sealing solution.

Often, the walls of houses made of OSB panels are not finished with anything outside. It is enough to process them with high-quality varnish.

Internal

Most often, a house made of OSB panels is painted or varnished inside. If the owners decide to resort to painting, then it will be necessary to remove the upper wax layer from the materials. To do this, you can use sandpaper. You will also need to apply a primer with a special composition with a gypsum or acrylic base, but you do not need to use water-based solutions, because as a result, the process of deformation of materials can begin because of them. When the specified processing is completed, the paint will surely lie on the OSB sheets in a very neat, even layer.

It is not recommended to use ordinary plaster for interior decoration of slabs. But the lining will be a very good solution. Thanks to this finishing material, a very comfortable and pleasant microclimate will be created inside the premises.

For interior work, you can also use wallpaper. But before sticking them, the owners will also need to remove the upper paraffin layer from the walls using emery. Then the surfaces are thoroughly putty, treated with two layers of primer. For additional strength, it is allowed to add a PVA solution to the wallpaper glue.

If the base of the floors is made of raw wood chips, then you can lay ordinary linoleum, carpet or beautiful parquet on it. The laying of ceramic tiles is not prohibited. The choice of the optimal material depends on the wishes of the owners.

Floor coverings may not be used if OSB-3 sheets were used during construction.Their surface just needs to be cleaned, degreased, sanded, primed, and then treated with several layers of high-quality varnish.

This will be enough. The furnishings in the newly built house will be neat and very cozy.

For more information about a house made of OSB panels, see the video below.

The comment was sent successfully.