How to make a do-it-yourself armature bender?

Rebar bending is a type of work that no construction can do without. An alternative to bending is to saw and weld the rebars. But this method is too long and energy consuming. Since the first batch of reinforcing bars was produced, machines for bending them have also been created.

The device and purpose of the bending machine

In the simplest case, a rebar bending machine includes a casing and a working mechanism. The first serves as the base on which the second is attached and rotated. Without a reliable base, you will not be able to bend the reinforcement efficiently - it must be securely fixed. The movement of the reinforcing bar (except for the part that bends in the right direction) should be completely excluded.

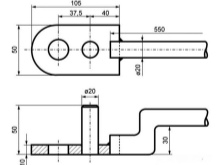

There are at least a dozen different drawings of the simplest home-made manual bending machine - they differ in the size of the working parts of the device.

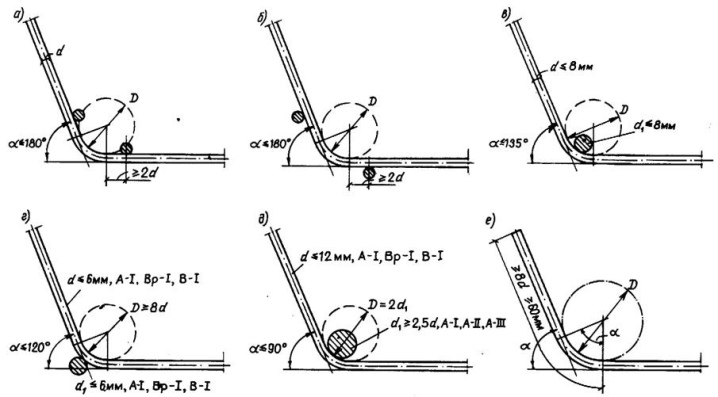

But all these armature benders are united by a common principle: the armature should not be bent sharply and at an acute angle - no matter how thick or thin the rod itself is. The basic rule for bending reinforcement is - the radius of the bent section should be at least 10 and not more than 15 diameters of the rod itself. An underestimation of this indicator threatens to break the reinforcement, which will sharply worsen the operational parameters of the frame assembled from the rods. When overstated, the structure, on the contrary, will not have sufficient elasticity.

Preparation of materials and tools

Before making a bending machine, read the existing drawings or make your own. As initial data, the thickness of the reinforcing bar and their number are important. The safety margin of the device, exceeding the efforts for bending the existing reinforcing rods, is chosen as large at least three times, if the business is put on stream, and you bend the reinforcement to a large number of customers, or a grandiose construction is planned.

If a drawing is selected, then the following tools and fixtures are required.

- Grinder with a set of cutting and grinding discs. Without it, it is difficult to saw a massive profile and reinforcing rods.

- Electric drill and matching HSS drills.

- Welding machine and electrodes.

- A hammer, a sledgehammer, powerful pliers, a chisel (file), a center punch and several other tools that no locksmith can do without.

- Workbench vice. Since the structure is strong, it must be fixed.

As materials you will need:

- corner profile (25 * 25 mm) 60 cm long;

- steel bar (diameter 12-25 mm);

- bolts 2 * 5 cm, nuts for them (by 20 mm in inner diameter), washers for them (can be grooved).

If the rod bend is made on the basis of another device, for example, a jack, then such a device must be present.

The device that you make weighs more than one kilogram. The increased weight and massiveness of the entire structure will provide the strength required for bending the reinforcement.

Manufacturing instruction

You can end up with a versatile armature bender that also works as a pipe bender. Such a device will turn out to be doubly useful than a simple machine, on which even a half-inch copper pipe for the "line" of the air conditioner cannot be bent.

From the jack

Prepare the jack. You will need a simple automobile - it is capable of lifting a load of up to two tons. Do the following.

- Cut equal lengths of 5 cm from the steel profile.

- Select a piece of reinforcement with a diameter of at least 12 mm.Cut it into pieces of the desired length using a grinder or hydraulic shears.

- Place the ends of the reinforcing bars inside the corner section and weld them to it. Connect the parts of the profile to each other. In this case, a 35 mm wide profile is allowed to be connected along its entire plane, and 25 mm parts are connected only by the end sides.

- Weld the resulting fixtures with each other. The result is a device that directly bends the reinforcement, it plays the role of a kind of wedge.

- Fix the resulting working part on the jack, having previously set it horizontally and vertically. An incompletely aligned structure would work ineffectively.

- Make a supporting T-structure. Its height should be 40 cm, width - 30.

- Cut out individual pipe-like pieces from the corner. Weld them to the frame. Use them to fix the jack.

- From the sides of the supporting frame, 4-5 cm from the working (bending) corner, weld two pieces of the corner profile. Weld the hinges to these segments.

Insert the jack in its designated place, place the reinforcement on the flexor and activate the jack. As a result, the reinforcement, resting against the hinges, will bend 90 degrees, acquiring the required bending radius.

From the corner

The simplest design of an armature bender from corners is made in the following way.

- Cut pieces of a corner 20 * 20 or 30 * 30 35 cm long and up to 1 m. The thickness and size of the angle profile depends on the largest diameter of the rods to be bent.

- Weld a pin to the bed - a base made of a U-shaped profile up to 1 m long... A piece of thicker reinforcement is suitable for him.

- Cut a piece of pipe of a suitable diameter so that it slides loosely over the welded pin. Weld a larger piece of the corner to it - make sure that the corner and the pipe are perpendicular to each other. Drill a gap in the corner in the place where the pipe is welded - for its inner diameter.

- Slide the corner with the pipe over the pin and mark where the smaller piece of the corner is welded. Remove the corner with the pipe and weld the second piece of the same corner profile to the bed.

- Weld one more piece of reinforcement to the end of the movable structure, which you will take on during work. Slide a non-metallic handle over it - for example, a piece of plastic pipe of a suitable diameter.

- Weld the legs of thick reinforcement to the bed.

- Lubricate rubbing surfaces - axle and pipe with grease, lithol or machine oil - this will extend the service life of the rebar. Assemble the structure.

The armature bender is ready to work. Place it on, for example, a large brick or stone so that it does not budge when you work. Insert the reinforcing bar and try to bend it. The device must bend the reinforcement with high quality.

From bearing

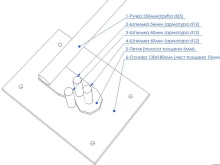

A bearing armature bend is made from bearings (you can take worn ones) and pieces of a 3 * 2 cm profile and pipes with an inner diameter of 0.5 inches. To assemble such a structure, do the following.

- Cut the profile pipe 4 * 4 cm - you need a piece 30-35 cm long.

- In the piece of profile taken for the handle of the assembled structure, drill a pair of holes with a diameter of 12 mm. Insert 12mm bolts into them.

- Install the nuts on the back. Weld them to the profile.

- At one end of the profile 3 * 2 cm, saw through a small notch for the bearing sleeve. Weld it on. It should be as flat as the hub of a bicycle wheel.

- In a piece of 4 * 4 cm profile, cut out the cuts to fix the sleeve. A shock absorber rod is used as a fixing part.

- Weld the lever to the profile structure. Its base is a 05-inch pipe.

- Cut a piece of angle 32 * 32 mm - at least 25 cm long. Weld it to a square profile with a 1.5 cm allowance. Insert a support from a strip of steel.

- Use a couple of pieces of plate and a piece of hairpin to make a movable stopper.

- Weld the arm to the supporting structure. Install the bearings and assemble the device.

The armature bender is now ready for use.Insert a rod with a diameter of up to 12 mm and try to bend it. Do not insert the thickest rod you have right away.

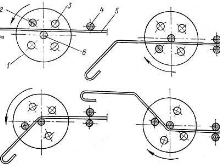

From the hub

A hub rod bend is similar to a bearing rod. As a finished structure, you can use the wheel hub and the base of an old car, from which nothing, except for the supporting structure of the chassis and body, is left. A hub is used (with or without bearings) and from a motorcycle, motor scooter, scooter. For thin rods with a diameter of 3-5 mm (they are often produced without a ribbed surface), even a bicycle hub is used.

Any bearings will do - even with a broken cage... The balls are used whole. The surface of the hub should be perfectly smooth, with a 100% round cross-section, which is easy to check with a micrometer. Erased (especially worn off on one side) balls make the structure "walk" from side to side. The role of a primitive separator here is played by a short pipe section of the corresponding diameter.

Both the balls and the piece of pipe holding them are calculated for the diameter of the bent reinforcement: the basic rule “12.5 rod diameters” has not been canceled. But new bearings with an armored cage will give the best effect and durability. In a corner rod bend, half of the hub is often used as a support (radial) pin.

Useful Tips

Do not try to bend the reinforcement with your bare hands by stepping on it. Even thin pins require at least a bench mounted vise and a hammer. Refusal of devices and a reinforcing machine is fraught with high injury risk - there were cases when such "daredevils" were seriously injured, after which they were taken away by "ambulance". Do not jerk the reinforcement.

The process should be smooth: steel, no matter how plastic it is, undergoes tension from the outside of the bend angle and compression from the inside. Jerks, too fast bending of the rods violate the cold bending technology. The rod heats up, receiving additional microcracks at the bend. The jerk can loosen and even break the material.

Do not file the reinforcement at the bend. Breaking is guaranteed in this case. Hot bending also weakens the steel significantly.

The bend should be smooth, and not polygonal and "wrinkled", as in heating and water pipes heated at the bend using gas welding or a blowtorch. Do not try to heat the bent rod in any way - in a brazier, a fire, on a gas burner, leaning against a hot heating element, an electric stove, etc. Even sprinkling with boiling water is not allowed - the rod must be at the same temperature as the air around it.

If you are unable to bend the rod, cut and weld both parts with the ends, at a right or other angle. Simple tying of such pieces in places of constant shock-tensile load (foundation, interfloor ceilings, fence) is unacceptable - the structure will delaminate in several years, and the structure will be recognized as emergency, dangerous for people to live (or work) in it. Do not use a rebar bending machine that is not designed for rods of the required thickness. At best, the machine will bend - at worst, the supporting-movable part will break, and you will get injured or fall if you apply too much force to the machine.

If the rebar machine is assembled on bolted connections - make sure that the bolts, nuts, washers are made of high quality steel, as well as the corners, rods, profile. Often, building stores and hypermarkets sell fasteners from cheap alloys, in which steel is diluted with aluminum and other additives that impair its properties. Poor quality bolts, nuts, washers, studs are often found. Check them carefully. It is better to overpay a little, but get good bolts made of alloy steel or stainless steel, than using those made of "plasticine" steel, which deforms easily with any tangible effort.

Such low-quality steel is used, for example, in the manufacture of hex keys, screwdrivers.

Avoid "consumer goods" fasteners - they are suitable, for example, for fixing roofing iron and plastic sheets, once screwed to the beams and resting on them. But these bolts are not suitable where a constant shock load is required.

Do not use a thin-walled profile used for the installation of plasterboard floors and siding panels for the manufacture of a reinforcing bender. They can't even bend a 3-millimeter rod - the corner itself is deformed, and not the bendable reinforcement. Even several such corners, nested one inside the other, will make the structure very problematic, bending with such a dubious device is unacceptable. Use a profile of normal thickness - the same steel as the bars themselves. Ideally, if there is a piece of rail for the device bed. But this is very rare.

A well-made armature bender will quickly pay for itself. Its primary purpose is to make a frame for the foundation of a private house and outbuildings, a fence as a fence. And if you are also an experienced welder, then you will begin to bend fittings to order, as well as cook doors, gratings, intake sections from it, then such a device will give you some extra money.

How to make an armature bender with your own hands, see below.

The comment was sent successfully.