Cellar caissons: varieties and installation technology

Owners of country houses and summer residents every autumn have a great opportunity to reap the fruits of their labors in the form of a rich harvest. But in addition to a sense of pride in their success, in addition to providing the family with pickles and fresh vitamins, the main problem of all gardeners, without exception, is added. They wonder where to store their supplies of vegetables and fruits. For these purposes, a certain climate is needed - constant temperature, lack of humidity, safety from rodents and insects, mold and mildew.

Until recently, such a storage place was the cellar under the house or the basement. However, this time-tested method is far from always justifying itself, especially if the groundwater is high on the ground. On the forums of gardeners, almost every season, the topic of cellar flooding, freezing or, conversely, an increase in temperature and humidity, about means of combating fungus and rodents, about additional ventilation, insulation, water drainage, is raised. People are forced to solve these pressing issues when they see how their lovingly grown crops begin to mold, rot or be destroyed by pests.

Peculiarities

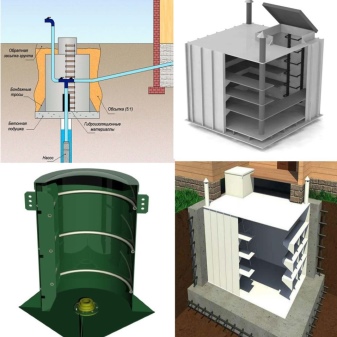

A way out of the situation was unexpectedly found in the field of shipbuilding. To prevent water from penetrating into the cellar and to maintain a constant temperature there, it must be absolutely sealed. That is, the caisson for the cellar is this hermetically sealed capsule that can be completely in water. Such a cellar can be made of concrete rings, provided that the joints are completely sealed. But modern manufacturers offer an alternative and more profitable option - plastic or metal caissons for the cellar.

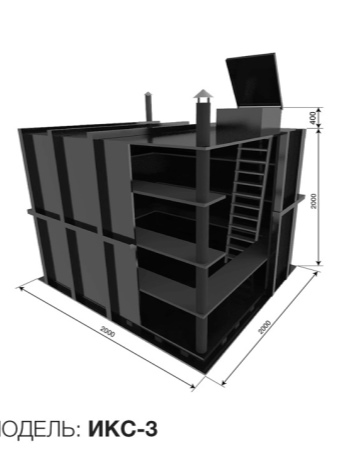

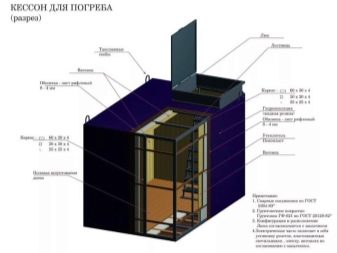

In fact, a caisson is an absolutely sealed container with an entrance hatch located on top of the structure. The volume of the container may vary depending on the needs and wishes of the owner. In shape, standard caissons are in the form of a square, parallelepiped or circle. The minimum size is considered products 1.5 x 2 square meters. m.

Manufactured caissons, as a rule, are already equipped with all the necessary elements.: a hatch, a ladder, and some models are supplied with shelves and boxes for storing vegetables.

The walls of the caisson reach 16 mm, this value is considered optimal to withstand the load of the outer soil layer.

The caissons are equipped with supply and exhaust ventilation, which ensures air circulation, creates a climate in the capsule and protects against condensation, mold and mildew.

Views

The caissons offered by the manufacturers differ in the type of material, while the internal filling is usually standard. The caisson can be made independently from reinforced concrete.

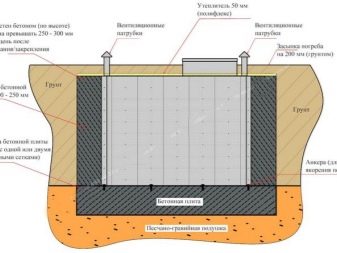

The construction of a reinforced concrete caisson involves the use of concrete rings, according to the technology of building a well or a septic tank. This option has a number of significant advantages:

- its weight is so heavy that it eliminates the risk of squeezing the container outward under the influence of groundwater and heaving soil;

- reinforced concrete rings are able to withstand the side and bottom loads of the soil.

For the rest, in order to properly equip a reinforced concrete storage facility, you will have to face some disadvantages, spend a lot of effort and finance:

- Concrete structures require high-quality waterproofing, all joints between the rings must be perfectly aligned and sealed. However, even this does not guarantee that the bonding material will not be destroyed over time by water or rodents. Hydro and thermal insulation will also be required outside the structure.

- To install a concrete storage facility, lifting equipment will be required, since even a few people will not be able to lift and lower concrete rings into the foundation pit.

- A solid foundation must be laid under the concrete rings so that the heavy structure does not sag.

Metal caissons are more popular due to their relatively light weight., and most importantly, the complete tightness of the product. Metal storage facilities offered by manufacturers are completely ready for installation. Models are made from solid steel sheets with a width of at least 20 mm, which significantly improves the quality of the product and prevents the risk of deformation underground. The sheets are welded into a sealed cube, equipped with a ladder and a hatch.

We can say that a metal caisson is a small version of a submarine that is not afraid of groundwater. Metal is necessarily treated with special anti-corrosion compounds, and is also equipped with a bypass valve in case water gets into the sealed compartment.

With sufficient metalworking skills, you can weld metal sheets yourself. It is important not to forget about the anti-corrosion treatment of the material.

Structures made of plastic have all the advantages of polymeric materials and represent the most modern way of arranging a cellar on the market. Plastic does not lend itself to moisture, does not need anti-corrosion treatment. Finished products are cast from solid sheets, so there is no need for waterproofing. Polymer models are unusually light in weight in comparison with analogs, their installation does not require the involvement of lifting equipment. Modern plastic caissons are equipped with all the elements necessary in the cellar, and the service life reaches half a century.

Of all the options presented, plastic products are the most popular. Lightness, economical price and absolute tightness make this type of caissons one of the best sellers. Metal caissons are not lagging behind in popularity and have positive reviews from buyers.

Metal models are popular with those summer residents who are not yet ready to entrust the storage of crops to modern plastic structures and want to equip a place for a cellar thoroughly and as reliably as possible. Reinforced concrete in this race loses in weight and a rather high price, however, such structures also have their adherents.

How to install?

Most products are ready for use immediately after purchase. The only exception is a caisson made of concrete rings. As a rule, a manufacturing plant or a distributor offers a turnkey installation of its products. The buyer only has to choose a place for installation, everything else will be done efficiently and quickly by qualified craftsmen. But if you do not plan to spend additional funds and have certain skills and experience, then the installation of the caisson can be done independently.

The installation of a finished product made of plastic, metal or concrete is carried out in several stages and has its own nuances.

The most important stage that determines all further actions is the determination of the place for the caisson.

Seat selection

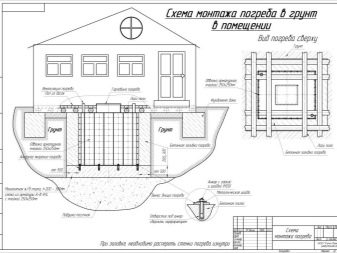

Of course, the most convenient location for a vegetable store will be the cellar under the house or the garage at the house. This will allow you to go down for supplies without going outside, which is especially important in the winter season. In addition, the arrangement of the caisson under the house will facilitate the installation of the ventilation system.

It is possible to install a caisson under the house only at the stage of building a building, or rather, immediately after laying the foundation.

The best option would be to include a caisson in the construction project in order to foresee all the subtleties in advance and eliminate errors, loss of time and additional expenses. If you are just planning to build a house, then it's time to think about storing the future harvest.

But in most cases, experienced summer residents are already thinking about storing supplies, when the house has been built a long time ago, and the harvest is great, thanks to experience and high-quality care. It will not work to build a monolithic metal or plastic caisson into an existing cellar, for this you would have to disassemble part of the house. The same applies to the installation of concrete rings.

Therefore, to install the caisson, any convenient place on the site is chosen that is suitable for the size of the future structure. At this place, it will subsequently be possible to erect an outbuilding, which will allow you to be under the roof when descending into the cellar, and at the same time a place will be added for storing agricultural tools.

Pit preparation

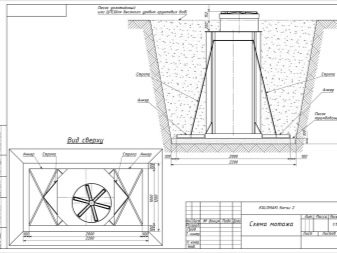

The easiest way to dig a pit is with an excavator, but a hole that does not exceed 3 meters in depth can also be dug with shovels. For this, the boundaries of the future pit are marked with a cord and pegs. The width of the pit is calculated based on the size of the container and adding another 0.5 meters to them along the entire perimeter. Additional space will allow for installation work, and will also serve as a place for laying heat-insulating material.

If the groundwater passes too close to the surface, then in the process of work, the gradual flooding of the pit cannot be avoided. In such cases, in the center of the pit, a water collector is arranged - a small hole the size of a shovel's bayonet, where water will collect. The hole is deepened as the pit is dug.

When the pit is ready, a "pillow" for waterproofing is lined at the bottom - a mixture of thick clay that will hold back water. From above, the flooring is sprinkled with sand and compacted well. Sand and clay will also serve as the bottom thermal insulation.

To strengthen the structure and keep it from being pushed out in heaving soils, an anchor plate is often used. Such a platform can be poured from concrete directly in the pit using mortar and reinforcement. In this case, it will take several weeks for the concrete to gain strength. It is easier and faster to use factory precast concrete slabs. The caisson is attached to the slab with brackets or steel cables.

As a rule, the lugs for fastening are already on the finished products, and when pouring the slabs yourself, they must be embedded in the concrete.

Mounting

Before you start immersing the device in the pit, you must take care of the ventilation holes and the places where they are led out. Do not forget that when making your own ventilation holes, you need to hermetically seal all joints and seams.

To install the product, you will need several assistants, a pair of round logs and a winch. Logs are lowered vertically along the edges of the pit; they will serve as guides and limiters.

With the help of a winch and logs, the product is lowered to the bottom of the pit. It is leveled and adjusted in level by swinging the structure. The next step is to fill the pit with the installed structure with greasy clay and sand from all sides. They will serve as excellent heat and waterproofing materials. Each layer is carefully compacted, right down to the manhole cover.

The final stage of installation is the most pleasant interior work. A ladder is installed, ventilation is regulated, racks and pallets are mounted for storing crops and blanks.

Tips for arrangement and operation

To make the caisson cellar as convenient as possible for storing food, it is equipped with various devices. The number of shelves and drawers, as well as their location, can be determined by the manufacturer and come with the product. If the caisson is made independently or does not include additional equipment, then the necessary elements will need to be made by hand.

- Best dWood is suitable for the manufacture of shelving - timber and ordinary sanded boards. Wooden crates filled with straw or sawdust are also a great place to store some vegetables.

- The staircase is most often made of the same wood or metal. The main condition for the installation of a ladder is its reliability and safety. The deeper the caisson, the more attention should be paid to the strength of the material for the stairs and the stability on it when descending, because a fall into the cellar can result in serious injuries. This is especially dangerous if the caisson is outside the house and it will not be possible to get help right away.

- Another important point in the arrangement of the caisson is lighting... As a rule, standard caissons do not provide for wiring in them, so you can use portable lamps or a lantern. But the best option would be to install battery-powered lamps. A rare appearance in the caisson will insignificantly affect the operation of the batteries and will not soon disable them.

- If the caisson cellar is outside the house, then after each closing of the hatch it should be covered with heat-insulating material. It can be expanded clay, moss, sawdust or peat. But in order not to complicate the process with natural materials, you can use any synthetic covering cloth or a piece of insulation.

- Cellar-caisson, like any closed room, needs periodic ventilation... Airing is best done in summer, preparing the store for the coming harvest season. Warm air will dry the room and remove accumulated particles of toxic gases. At the same time, an inspection of the cellar is carried out, cracks and defects are identified and eliminated, if the caisson is concrete. The functioning of the ventilation is checked and the entire room is cleaned.

For information on how to install a plastic caisson, see the next video.

The comment was sent successfully.