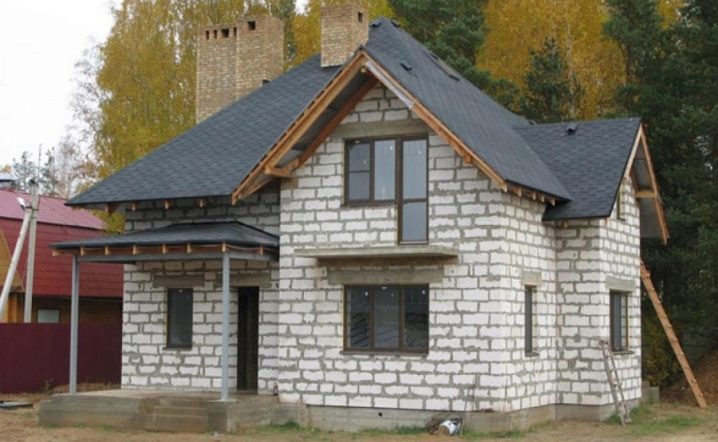

Beautiful projects of one-story houses made of aerated concrete

Gas block houses today are one of the most popular options for suburban construction. They are suitable both for permanent residence and for summer residence - as a summer residence. This widespread use is easy to explain - aerated concrete is inexpensive, easy to operate, and has good thermal insulation quality.

A gas block can be used to build a one-story or two-story house, and even a "one-and-a-half-story" one with an attic. At the request of the owner, aerated concrete houses will house a sauna, garage and / or basement.

Design features

Aerated concrete is called light cellular concrete. It is obtained from a mixture of cement or lime, silica sand, aluminum powder and water. The chemical reaction, in which aluminum powder and lime enter, causes the release of gases, due to which a porous structure is created inside the block, distributed in equal proportions.

Due to their porous structure, aerated concrete blocks have the following properties:

- good thermal insulation;

- low flammability and high fire resistance - 70 minutes;

- excellent sound insulation;

- frost resistance - from 50 to 100 cycles;

- accumulation and preservation of heat, due to which a constant air temperature is maintained in the house;

- saving material and mortars for masonry due to the flat and smooth surface of the gas blocks;

- long service life - up to 100 years;

- easy material handling.

Like projects from other building materials, aerated concrete houses are divided into buildings of economy, medium and business class.

The first group includes the most affordable construction options. As a rule, in this situation, we are not talking about the second floor, the maximum that fits into the budget is the attic.

The area of such buildings is about 20-30 square meters. meters. Accordingly, on a large summer cottage such a house can become a guest house, along with the "capital" house in which the owners live. If the site is small, and the budget is limited, the aerated concrete structure may well become a dacha where the owners will spend the summer without any problems.

On average, the cost of such structures ranges from 300 to 400 thousand rubles.

The attic, although not considered a full-fledged floor, allows you to significantly expand the area of the house. Most often, it is in it that the bedroom is located, which makes it possible to make a living room below, combined with a kitchen block, a spacious bathroom and a hall. At the same time, the construction of an attic does not require as much costs as for the construction of a second floor, and a reinforced foundation is not needed either.

Projects of aerated concrete houses of the middle class (with one floor and without an attic) are being developed with an area not exceeding 50 sq. meters. Regardless of whether there is an attic or not, the cost of the project will be about 900 thousand rubles.

Again, if there is an attic, you can take out the master bedroom and the children's room (if the family has children) into it.

As for the first floor, since the area is quite large, there are two options for using the space:

- two or three large rooms (living room, kitchen-dining room and premises at the request of the owners - billiard room, gym, study);

- four to five small rooms.

If it is planned to live in the house permanently, it is imperative to provide for a technical room (boiler room).

It should not be forgotten that a veranda can be attached to the house and the dining room can be brought into it. What could be nicer than having a cup of tea while looking out at a blooming garden?

As for business-class aerated concrete houses, these projects are unusually comfortable, these are full-fledged cottages. Their cost is from two million rubles and more, and the area is at least 80-90 sq. m.

Luxury cottages include spacious rooms:

- bedrooms;

- kitchen;

- separate dining room;

- block of auxiliary premises (boiler room, storage room);

- living room, possibly with a bay window;

- wardrobe;

- cabinet;

- bathrooms and toilets, possibly with a sauna;

- basement with standard ceiling height;

- additional premises, depending on the owner's wishes - a garage for one or two cars, a heated veranda, a greenhouse with a winter garden.

An open summer terrace with a barbecue area can be attached to the house. In short, the owner's flight of imagination can be limited only by his budget. Otherwise, there are no barriers to building your dream cottage from aerated concrete blocks.

This material allows you to build houses of all the listed comfort classes in the southern regions, and in the middle lane, and in the north. Aerated concrete is compatible with any type of heating - stove, fireplace, boiler.

In addition, it is strong enough to build two-story houses out of it. That is why it is so widely used in the construction of country houses.

Choosing a foundation

Compared to other building materials, aerated concrete blocks are lightweight. It is for this reason that aerated concrete houses do not require the construction of a complex and expensive foundation. The only condition is that the base must be correctly calculated. Since a wall made of aerated concrete blocks is a rigid, non-plastic structure, if the foundation sags, it will crack.

What will be the type of foundation, they decide by analyzing the quality of the soil and the parameters of the house itself. Low-rise houses are built from aerated concrete - up to 3.

The most suitable types of foundations for such structures are:

- tape;

- monolith;

- piles;

- columnar.

The most expensive of the above will be the first and second. They require a large amount of both reinforcement and concrete, and this entails costs both in terms of finance and construction time.

Therefore, if you do not want to invest a large amount of labor and money resources in the construction of the foundation, it is better to stop at the columnar-tape option. This will help save on slabs at the base of your home.

However, there are situations when only a strip base can be used to build a house. For example, if the soil is sandy, heaving and prone to shear. Also, a strip foundation is needed where the foundation is supposed to be shallow - from 60 cm.

A monolithic foundation is usually laid where the groundwater is located high to the surface. Slab bases are divided into ribbed and non-ribbed.

If there are no stiffeners on the slabs, its level of strength decreases, and such a foundation can be used for a small structure - a pantry or a shed. For larger structures, it is better to take a shallow monolithic slab with reinforcing stiffeners.

Its properties are as follows:

- when the soil freezes, it retains its integrity, without sagging or cracking;

- high bearing capacity;

- resistant to deformation during ground movement.

These properties of a monolithic foundation will make it possible to build on it not only one-, but also two- and three-story houses made of aerated concrete blocks. But it must be borne in mind that this type of base does not allow basement equipment, in addition, it is not budgetary.

Pile foundations and columnar foundations are much more economical options, as the material consumption is much less, it is easier to erect it, and both are suitable for difficult soils.

Installation of both piles and pillars is carried out along the perimeter of the building in a pointwise manner. The indentations for the posts are prepared in advance.

Further, that the pillars, that the piles from above are connected by a grillage - a reinforced concrete integral horizontal frame.The grillage functions are to evenly distribute the load on the piles / pillars and combine them into an integral structure. On the grillage, the house is being erected.

If the soil is weak, frozen, heaving or watered, the pile foundation can also be used, but the piles must be of a special type - screw. Then you don't even need to level the land.

The advantages of pile and columnar foundations are:

- the ability to put them at any time of the year;

- the settlement of the house on such a basis is less and occurs evenly;

- the grillage enhances the stability of the structure.

A strip foundation is better suited for two- or three-story houses.

It is undesirable to take aerated concrete blocks for the base of the house, since this material is rather fragile and non-moisture resistant, groundwater will easily destroy it. For a strip foundation, an FBS (solid foundation block) weighing about 3 centners is suitable.

Shallow tape base is suitable for houses without a basement. If a basement is needed, then the base will need to be buried, with a standard depth of about 150 cm.As a general rule, the trench should be located 20 cm deeper than the level of freezing of the soil.

The width of the trench is calculated in each case individually and depends on how much the building weighs. Wall thickness is another parameter that must be taken into account when calculating the foundation. Therefore, the width of the base should exceed the width of the wall by 10 cm. The wall is located in the middle of the trench, and 5 cm of the trench remains on each side of it.

To find out the bearing capacity of the soil in the region in which the construction is underway, you can contact both the Internet and the specialists of the design workshop. If you know what type of soil is where construction is planned, it is not difficult to find out.

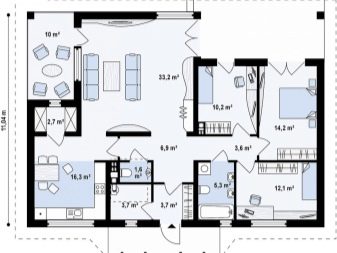

Blueprints

The project of a one-story house made of aerated concrete can, if you have some skills, develop yourself or ask for help from the appropriate specialists.

If you plan to build an economy or middle class building with an area of 8 by 10, the calculation and drawing can be developed alone.

In the case when you "swung" at a luxury cottage 10x10 with an area of 100 sq. meters or even more - 150 sq. meters, it is better for professionals to help you. Since a house of such an area is not cheap, you should not try to save money on its project, because this is a plan on the basis of which your dream will come true.

In accordance with the current regulations, a house made of aerated concrete blocks of "one" storey must be erected as follows:

- wall blocks should be used in conditions in which the humidity does not exceed 75%;

- external walls must have a frost resistance grade - F25 or higher, and for rooms with high humidity - not lower than F;

- vertical and horizontal seams should not be thicker than 1-2 mm;

- the adhesive solution used for masonry walls must have a water-holding capacity of at least 98%, as well as a compressive strength of 10 MPa;

- load-bearing external walls must have a recommended width of 600 mm, and self-supporting walls - from 300 and more;

- metal elements used in construction are made of stainless or anodized steel;

- floor slabs on the basement or second floor must have an abutment depth of 120 to 150 mm.

Advice

Often a person, having met an ad “turnkey gas block houses” and seeing that the cost is low, rejoices and believes that a way out has been found. But this is not always the case, especially in cases where low-quality material is used for the construction of such houses.

In most cases, such firms make aerated concrete blocks themselves, not observing the production technology. The material is obtained that does not meet the requirements for aerated concrete, and is often even harmful to health.

Artisanal production conditions reduce the cost of the material, but these perceived savings can result in costly repairs.

Therefore, first of all, you need to be interested in the quality of the material, whether it has certificates of conformity to GOST, as well as what documents the developer has.

See one of the projects of a one-story house with an attic made of aerated concrete in the next video.

The comment was sent successfully.