Two-story frame houses: drawings and design diagrams

The housing issue does not lose its relevance in our country. For many families, he comes first. An alternative to an expensive apartment can be the construction of a wooden house in the suburbs. The most popular are frame houses. When installing such objects, new technologies and high-quality materials are used.

Peculiarities

There are a huge number of residential building projects based on a wooden frame. Two-story frame houses are widely recognized. In Russia, in most of the territory there are frosty winters, two-story houses fully comply with the requirements and standards and can be fully used for the coldest seasons. The frame is the basis of such houses.

There are two types of frameworks:

- Platform. This type implies a phased construction of the object. The advantages include the fact that it is easy to install and has a minimum number of prefabricated elements.

The work algorithm is as follows:

- floors are collected at the base of the house, they are guides that will hold the entire frame of the house;

- then the bearing racks of the first floor are fixed;

- the overlap of the first floor is made, which will be the basis for the second;

- the racks of the second floor are being placed, the floors are being assembled, which will also be the floor of the attic.

- Through. To implement the through wireframe method, noticeably more effort is required. Through posts are fixed at regular intervals with other nodes in such a way that deformation does not occur. The racks themselves are placed without interruption through the entire frame to the roof.

Very often, preference for frame houses is given by people who are impressed by the classic style, when load-bearing structures serve as the basis of the interior. The frame is made of timber, which is rigidly attached with steel anchors or bolts. The walls of the building are sheathed with special slabs (DSP). All wooden elements are treated with antiseptics and primers, which guarantee fire resistance and insect protection. Firms professionally engaged in the construction of such objects give a guarantee of 40-50 years.

Two-story frame houses have such advantages as:

- the design of a two-story frame house contains advantages that stone buildings do not have. Such facilities require much less heat and ventilation resources;

- from the point of view of ecology, a frame house can be called a standard, since it is made of a material that does not contain toxins;

- fire safety issues have been resolved at the proper level: wood is treated with a special primer, it successfully resists the effects of high temperatures;

- efficiency in the construction of the facility (3-4 months);

- low cost.

The list is far from complete, because there are a number of technical characteristics that make such objects attractive to many owners.

Factors that affect the operation of a wireframe object are as follows:

- the quality of the materials used for the walls;

- used insulation;

- type of construction technology.

The disadvantages of frame houses include the following:

- the ventilation system must be well thought out in a constructive sense;

- to reduce the risk of short circuit to zero, wiring should be done correctly;

- sound insulation is also an important factor, therefore, special attention should be paid to this factor during construction;

- in the interfloor spaces, a remedy for mice and cockroaches should be placed, since there is a possibility of their appearance.

Projects

Two-story frame-type houses are in great demand in Russia, especially in the following formats:

- 10x10 m;

- 9x9 m;

- 7x9 m;

- 6x8 m;

- 8x10 m;

- 8x8 m.

For them, there are standard drawings that are easy to find on the Internet. Often, options are practiced when the main project is taken and finalized by the homeowner to suit his needs. Design is often ordered from a construction company that builds frame houses. The total area of such housing ranges from 50 to 120 square meters or even 150 square meters. m. The roof is most often made of materials such as metal, slate or ondulin.

A two-storey frame house provides ample space. If you wish, you can make an extension to the main house: a terrace or veranda of 6 by 8 m or 6 by 12 m in size. Often, in frame houses on the second floor, you can find bay windows that are placed on the facade. These lightweight structures are used as a veranda, made in both summer and winter versions. The base of the bay window can be either a metal channel or a wooden beam. It is worth considering some projects in more detail.

Frame two-storey house 8x8 m

There are many modifications of frame houses of this format. The total area of the building is about one hundred square meters, of which the usable space is 68 square meters. meters, which is enough for a family of 4 people. The foundation can be tape or concrete blocks. Recently, it is often possible to find also a pile foundation, which is not inferior in strength and longevity to a concrete foundation.

The advantages of a pile foundation are as follows:

- no need to wait six months until the material shrinks, as is the case with a strip foundation;

- installation of piles takes 1–2 weeks, their cost is lower than casting a foundation from concrete.

Traditionally, the ground floor houses the kitchen and utility rooms, while the second floor usually houses the lounges and the living room. Various external finishing is allowed.

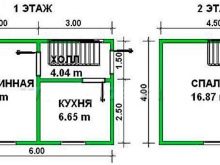

Two-storey house 6x6 m

Such an object covers an area of only 65 sq. m.

The following premises can be presented in it:

- household;

- wardrobe;

- children's.

House size 6x4 m

The area of 6x4 m has a minimum of rooms. The usable area inside the facility is about forty square meters. On the first one can be located utility rooms, a kitchen and a living room. The second floor is usually reserved for rooms such as a bedroom, a nursery and a living room. The foundation is usually made of reinforced concrete.

The frame is made of a beam of 10x10 cm. The slabs are beams measuring 12x15 cm. Outside, such a house is sheathed with OSB plates. The insulation of the outer walls of the 1st and 2nd floors is made of 20 cm thick Isobox basalt slabs. The structure is finished outside with siding, and inside the walls and partitions are sheathed with clapboard and plasterboard.

DIY construction

It makes sense to differentiate step-by-step instructions for building a house into several stages.

- Preparatory and design work. The site should be cleaned and slopes determined. After the flat area is ready, the marking begins in accordance with the pre-approved plan. It is necessary to observe accuracy so that in the future the object does not observe deformations and distortions of the walls.

- Foundation. The weight of the frame house is relatively small and the load on the ground is negligible. If the house is located in a lowland, where there is an excess level of moisture, then it is wiser to build a pile-screw foundation. The foundation is often made of reinforced concrete slabs, since it is inexpensive, characterized by versatility, strength and durability.Sometimes slabs are used as a base for a concrete floor, which saves additional resources on floor installation. If the object will be located on a hill, then you can also make a strip shallow foundation.

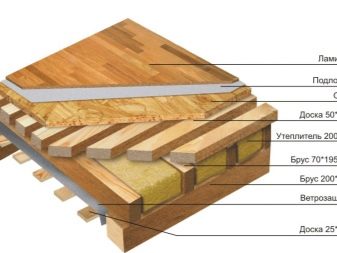

- Floor. The floors can be either concrete or made of planks and beams. If the foundation is strip, then the concrete floor is created from lightweight expanded clay concrete, which is inexpensive. If the floor is mounted entirely of wood, it is necessary to create a strapping from a beam of 10x15 or 15x15 cm. The choice of the size of the timber depends on the thickness of the wall and the dimensions of the space between the piles. The greater the distance between them, the thicker the timber should be. A bar of 150x150 mm or 150x200 mm is often used. A timber strapping allows you to evenly distribute the load over the entire plane of the floor, increase its rigidity and additionally strengthen the frame of the object. The easiest stage is to fix the lag. The distance between them is determined by their parameters. There are special tables where all the standards are spelled out in detail. Insulation is laid between the guides, which must be wrapped in a vapor barrier film.

- Walls. First you need to determine what the height of the walls will be. If their height is 3 meters, then the vertical racks are made 285 cm. The distance between the racks is dictated by the parameters of the insulation sheet. If the insulation consists of technical cotton wool, then it is made 1.8 cm less so that the installation is carried out by the spur method. Racks are attached using metal corners, which are screwed in with self-tapping screws. Jumpers are mandatory between the racks. Much depends on various parameters. How many jumpers should be installed should be determined in the working order. During the installation of the structure, it is imperative to use a plumb line and a good two-meter level. These tools are simple and effective, they do not allow vertical guides to deviate. After the racks are installed, the top strapping is made, the same board is used as for the floor. The top harness is mandatory, as it creates the necessary rigidity, which will not allow the vertical guides to "walk" in different directions if they are subjected to loads. Sheathing the house outside with OSB sheets also gives the entire frame additional rigidity. The guides of the inner partitions are used as additional stiffeners.

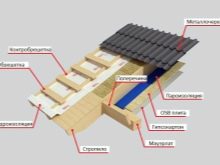

- Roof. If the frame is done correctly, then the installation of the roof will not take much effort. The choice of roof largely depends on the characteristics of each project and the personal preferences of the customer. Flat roofs are not very popular in Russia, since in winter a lot of snow accumulates on them, which gives an unnecessary load. The most popular are gable or pitched roofs. The angles of inclination in them can be from 10 to 47 degrees.

It should be remembered that the presence of additional slopes complicates the installation.

The optimal angle of inclination of the roof depends on the material from which it is made:

- corrugated board - from 11 degrees;

- slate - from 12 to 58 degrees;

- euro slate (ondulin) - from 7 degrees and above;

- ceramic tiles - 12–58 degrees;

- polymer sand tile - 17–62 degrees;

- bituminous tiles - from 11 degrees without limiting the maximum slope;

- metal tiles - from 17 degrees.

Warming

Basalt slabs are a very effective and inexpensive insulation material. It is used to treat walls and walls, floors, roofs and the space between floors.

Beautiful examples

A typical factory-assembled 2-storey frame house is a classic option.

A frame house of more than 100 square meters with a balcony looks stylish and elegant.

A two-storey frame house with a fireplace looks charming.

You will learn how to build a frame house from a bar in the following video.

The comment was sent successfully.