Facade thermal panels: features of choice

In the past few years, cladding with thermal panels for thermal insulation of the facade has become more and more common in our country due to the growing technical requirements aimed at providing the necessary indoor comfort. Insulating any building is the first step towards saving heat and reducing the amount of heat consumed inside.

Description

When it comes to cost, performance and aesthetics - not to mention maintenance and durability - evaluating cladding materials and façade systems is more challenging than ever. As with any product, you need to weigh the pros and cons to achieve the desired result. The wide range of offerings makes the selection process easier, but individual qualities entail restrictions on the use of some types of finishes.

Not so long ago, insulation and decoration of facades were carried out only separately. For the finishing processes, some materials were required, to create a barrier from the cold others. Today this method is also widely used, and often the ideal appearance is achieved at the expense of indoor thermal insulation. Recently, there is a good alternative combining two in one, it is such an economical solution.

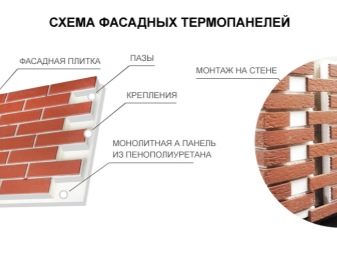

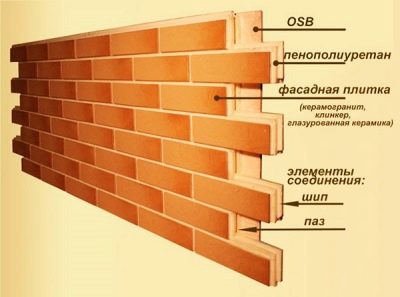

Facade thermal panels do not need additional processing after installation. Inside there is a layer of heat-insulating material made on the basis of polyurethane foam. Today it is considered the best in a long list of similar materials with similar properties and characteristics.

Polyurethane foam is significantly superior to polystyrene and other materials. Facade panels have a protective layer of composite material on the outside.

The builders and the consumer were able to appreciate the product due to the variety of colors, reliability and aesthetic appeal.

Office buildings and warm private houses decorated with such facades look modern and luxurious.

Polyurethane is a synthetic polymer material that is a kind of plastic. It is obtained by the reaction of two liquid components - polyol and isocyanate. When mixed, the elements react, foam and expand. When interacting, the mass solidifies, forming a fine-grained structure, which is more than 80% and consists of tiny gas bubbles. A distinctive feature is the minimum thermal conductivity of the air.

Thanks to its unique structure, polyurethane foam is unrivaled by any known insulation material. Thermal conductivity coefficient in different conditions 0.02 - 0.03 W / (m • K).

The minimum values allow the panel to be thinner, thus saving valuable space. If we compare the brickwork and this material, then the thickness in the first case is 50 centimeters, while in the second it is only 2 cm. Polyurethane foam perfectly withstands significant loads. With a high degree of elasticity, this insulation is able to withstand mechanical pressure in the medium range.

Lightweight foam allows you to carry out installation work without much physical effort, it does not affect the overall structure and does not require additional reinforcement. Moreover, it does not load the front and foundation of the structure. With a closed structure, it is an excellent waterproofing material.Products from polyurethane foam are absolutely not afraid of exposure to water.

Thermal insulation protects against moisture, corrosion, mold, does not form condensation on the walls and is not susceptible to the action of microorganisms or small rodents.

The service life of the product is 15 to 50 years and depends only on exposure to ultraviolet radiation. The only weak point is sunlight. Under its influence, the coating turns yellow and loses its properties. In the absence of UV radiation, the period is at least 50 years.

The material also has some other features. By design, it is a diffuse open and inert panel. The dew point does not exceed the permissible value, so there are no problems with tightness and ventilation (no gaps in the rear of the facade are required).

Reliable and precise connection of surfaces excludes the appearance of "cold bridges", condensation, harmful microorganisms. The panels have grooves and ridges to help prevent excess moisture from collecting in rainy weather. As a result, the building acquires not only the best aesthetic characteristics, but also excellent insulation, which keeps it warm in winter and cool in summer. Today you can buy material at quite affordable prices.

The thermal lining system involves laying a 6 mm thick ceramic board on top of an insulating layer, the thickness of which is determined according to calculations.

It requires a mechanically resistant support designed using a system of covering and stacking panels of expanded polystyrene or extruded polystyrene with high mechanical tensile and compressive strength and low modulus of elasticity, capable of supporting the weight and stress created by the material and thermal expansion.

The insulating layer should have a rough surface, a square profile and not have protrusions more than the thickness specified in the calculations. Achieving the desired result in terms of thermal insulation and durability of outdoor coatings is closely related to careful and correct design at all points that a thermal bridge can create.

It is the main culprit in heat transfer through building walls, dramatically increasing heating and cooling costs. The panels offer the ability to reduce these areas by placing a barrier outside. External insulation systems involve installing the material on the outside of a wall with a finished textured facade.

Main characteristics:

- in this case, the plumbing and electrical systems do not need to be moved, providing a more efficient modernization;

- meets environmental standards, both current and future;

- increase thermal efficiency and comfort by reducing humidity and improving building protection;

- meet a range of environmental standards;

- reduced maintenance costs;

- visually appealing: exterior finishes are available in a variety of textures and colors, so you can choose the perfect combination for maximum aesthetic appeal.

The consumer is offered a long service life. Slabs provide a unique palette of smooth and rough textures, ruddy, vibrant, muted and other colors as cladding material. This type of finish is currently popular because it is attractive, aesthetically pleasing.

Thermal panels are produced by pouring liquid polyurethane components into specially prepared molds with ceramic tiles. During the reaction, the components foam and solidify.

The material allows you to significantly save on construction and decoration.

The thickness of the block is selected based on the climatic conditions in the region. Most of the new buildings are equipped with thermal insulation panel cladding, which meets the necessary requirements for façade systems.It is installed directly on the outer wall, which eliminates the need to apply plaster and paint.

Decorative advantages: a variety of materials, a wide range of colors, a variety of textures, sizes, opening up new possibilities for the architecture of buildings in general and their individual fragments.

Ceramic tile panels have many advantages over other similar products, including:

- combine two properties - thermal insulation and environmental friendliness;

- have a minimum load on the foundation and load-bearing walls;

- provide additional noise insulation and protection;

- retain their density during heavy showers.

Views

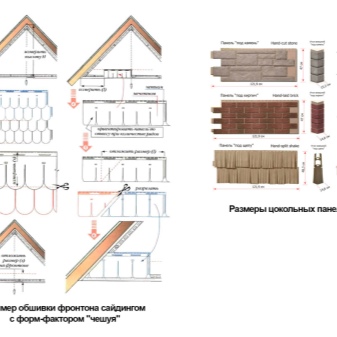

As a building and finishing material, this facing product has the following varieties:

- under a brick;

- under the tree;

- under a stone;

- with marble chips;

- metal panels.

Steel are suitable for vertical or horizontal applications. The eco-product is manufactured for facades to order with the desired pattern and is delivered ready-made to stores. For corners, wall panel options are made of foam at an angle of 45 degrees. There are transitions for window and doorways.

The classification may look like this:

- material - polystyrene foam, polyurethane foam, their combinations, extruded polystyrene foam;

- joint method - “thorn-groove”, joining of rectangular elements with smooth edges;

- facing material - granite, concrete, ceramics, clinker tiles and others.

Manufacturers overview

Main manufacturers in Russia:

- Facade Materials Workshop;

- FTP-Europa;

- Termosit;

- "Fride";

- Forska.

Among the main manufacturers, it is worth highlighting FTP-Europa - a company engaged in the sale not only of its products, but also of other factories. It has established itself in the reviews as a manufacturer of high quality material. The covering is made of porcelain stoneware, only an insulating layer is made from domestic.

There are good patented panels from Termosit... The production process is a full cycle, the company has created a quality control service, therefore, consumer characteristics are at a high level.

Natural materials are used in the decoration of Russian production from "Fride"... This includes porcelain stoneware, ceramics, stone. As a heater, polystyrene foam, the joints are made in the form of a thorn-groove.

GammaStone AIR Is a modern, environmentally sustainable system capable of meeting the most ambitious and modern stylistic trends in architecture. It also optimizes functional requirements, practicality and comfort. The material is the result of an intensive research process and is a response to the widespread need for effective thermal and acoustic insulation for homes and public buildings. It is used with structures and materials that at the same time guarantee a permanent aesthetic beauty.

GammaStone AIR is an excellent and unrivaled cladding material, today it is the most suitable option available on the international market for ventilated facades.

This innovative panel system was developed in collaboration with the largest and most reliable companies. Painstaking work has allowed us to achieve the best results in terms of insulation, protection from weather conditions and from external noise.

The panels provide ease of installation, versatility in architectural design, original stylistic solutions with a wide selection of marble, granite, porcelain slabs and large stone products.

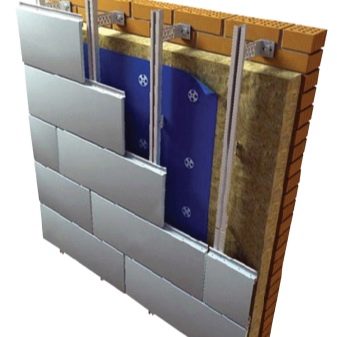

GammaStone AIR ventilated facades are really reliable. The panels are subjected to rigorous testing. They are installed on a metal suspended structure attached to the wall of the building with layers of insulation.

Pros and cons of the material

Among the main advantages, there are several advantages.

- Efficiency. Due to their manufacturing characteristics and design, the panels simultaneously perform two functions. First of all, they provide thermal insulation of the building, as well as decorative cladding.

- High thermal insulation. Provided with seamless installation.

- High waterproofing. The walls and surfaces of the facades are protected from the natural effects of moisture. In addition, the front mineral layer resists mold and mildew.

- Range. The consumer can choose his own version from dozens of colors and textures.

- Durability and ease of use. Do not require any maintenance. High temperature manufacturing technology provides the desired strength and aesthetic characteristics that last for decades. The durability and reliability of the panels is confirmed by long-term operation in many regions.

- A light weight. Thanks to this feature, the construction of the building does not require additional preparation and strengthening work before installing the facade system. This condition excludes overloading of the foundation, which allows the use of material for finishing walls with a height of more than 70 meters.

- Easy installation. Installation is carried out using special rails and simple tools.

- Installation at any time of the year. Does not require special equipment or specific temperature conditions.

- High aesthetic properties.

- Environmental friendliness. The construction is based on rigid polyurethane foam. It is a non-toxic material that does not pollute the atmosphere with harmful substances. It is absolutely safe for people. The front layer is made of composite material and mineral particles. They are also harmless to human health and life.

Like any material, this one also has some disadvantages, albeit a few of them:

- attracting professional workers;

- significant costs at first.

How to choose?

There are many exterior facade systems with insulation to choose from. It depends on the type and scale of the building, planning requirements that can affect the appearance of neighboring buildings.

Panel designs incorporate structural members to provide lateral and vertical wind resistance and other environmental influences, as well as parts that envelop the building, ensuring resistance to weather conditions, as well as thermal, acoustic and fire resistance properties.

Such a product allows you to change the appearance of a building in various ways. The variety makes timber house panels an innovative option for architects. There is a wide variety of different formats and mounting options that create a completely different character for a building.

The gaps provided between the panels allow the façade to act as a ventilation system that traps moisture. Double hardened acrylic resins provide effective weather protection suitable for balconies and cladding. Other properties include optimum lightfastness, double hardening, scratch and solvent resistance, impact resistance, frost resistance. The product is manufactured in laminate presses under high pressure and temperature.

When choosing products, you should pay attention to the features of different models. The manufactured product under the stone will delight you with a respectable appearance, but it is distinguished by its high cost.

There is a wide variety of panels on the market that imitate wood texture in a quality manner. They are ideal for small houses, summer cottages, where you want to create a special comfort.

If you choose a model for a brick, then such a material will resemble real brickwork not only in appearance, but also in texture. It is not so easy to distinguish from the original.

In order not to be disappointed in this type of finish, it is always better to choose a panel with insulation for outdoor decoration. It is suitable even for a wooden house, the only difference is in the method of installation.

How to Prepare?

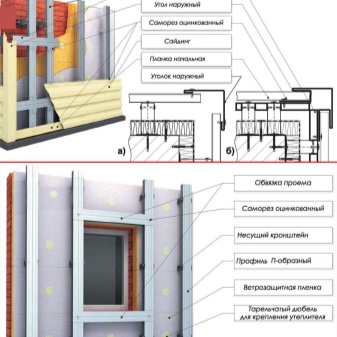

Polymer finishing outside the walls is mounted using frame technology. The main thing is to correctly install the lathing, which in most cases is made of wooden blocks, and sometimes from an aluminum profile.

The construction of the frame is the main preparation of the wall, if it is even. If this condition is not met, then the preliminary work on the organization of the cladding is reduced to additional processing and leveling the surface.

The first profile must be installed perpendicular to the ground, at the point that is considered the lowest at the facade. This is the so-called starting bar. The rest of the horizontal elements are attached 50 centimeters from it.

Fastening is carried out using self-tapping screws and dowels. Now you can set vertical guides.

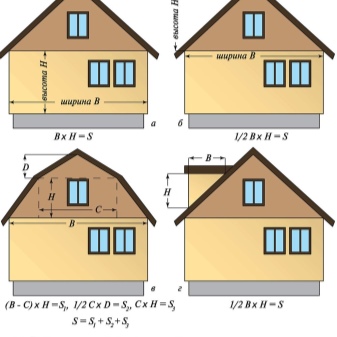

Calculations

To understand what the need for a building material is, you need to find the total surface area. From the obtained value, the sum of the area of doors and windows is subtracted and 10% is added, which are taken away during work, cuts and overlaps. The resulting figure is divided by 4.55, that is how many square meters. m is in one package of slabs.

The amount of the required starting bar for the insulation panels is calculated based on the perimeter of the building. The width of the doors is subtracted from the obtained value and divided by 3. In order not to be mistaken, add 5% of the received number.

Outside angles are determined by the sum of the heights divided by 0.45 m. For correctness, add 5% of the value obtained.

One panel requires 5 fasteners, the corner element takes 4, and the curb 2. The fastening of the starter strip is at least 10 elements if the fastening is done after 30 centimeters.

When making calculations, it is worth taking into account not only the covered area of the walls, but also heat loss., in accordance with which the material of the required thickness will be selected in the future.

- The quantity U is a measure of how much heat is lost through a given thickness of a particular material, but includes three main ways in which heat loss occurs - conduction, convection, and radiation. This is a measure that is always applied in the Building Regulations. The lower the U value, the better the heat insulator is the material. The U value provides insight into the consequences that thermal performance has when it comes to complying with applicable building codes.

- R-value is a measure of resistance to heat flow through a given material thickness. Thus, the higher the R value, the higher the thermal resistance of the material and, therefore, the better its insulating properties. Heat moves inside and out of a building in several different ways, and the R value only takes into account conductivity, but does not include convection or radiation.

Subtleties of installation

Boards should be laid with wide gaps in accordance with local climatic conditions. Structural connections are established in accordance with the dimensions of the unit. Expansion joints should also be used along corners and ridges (and in any case every 9-12 m2).

Clinker tiles are protected against water ingress and damage by installing suitable seals or metal openings at the top and bottom.

The construction of the material includes polyurethane foam and a composite mineral layer. The first component is the basis of the entire product structure, and it implements the isolation function. The polyurethane foam layer is protected by a textured material. The front is environmentally friendly and almost indistinguishable from natural wood or stone. The finished product is a complex whole.

Working conditions directly depend on the workload. Facade panels can be installed easily and without any additional tools. A screwdriver, screws, circular saw are enough for this.

For a correct installation, several steps are required.

- Mark the horizon around the perimeter of the facade. Place vertical beacons.

- Place the first row of panels on a horizontal profile. Treat the seams with polyurethane foam.

- Install the next row.

- Qualitatively process the existing seams using a special tool. The procedure is performed at a positive air temperature.

The facade can be mounted at any time of the year, since the installation does not provide for work with building mixtures.

The panels form a self-supporting structure, since there are practically no vertical loads in it. They are mounted on various hard surfaces: aerated concrete, beams, bricks, plaster. There is no need to create an additional framework. However, if the geometry of the facade is broken, it is advisable to use a screed. By adjusting its thickness, you can quickly level the surface.

Due to its low weight, the material is easy to install. Installation of facade slabs is carried out by installing plastic dowels. This design is not too complicated, but at the same time it is quite reliable.

The terminals create a level, crack-free surface. They protect the surface of the building from the effects of precipitation, temperature changes, thereby maximizing the service life of the entire structure. There are special panels for the corners.

Modern techniques offer a wide range of work and fastening techniques. This range includes the production and sale of aluminum facade consoles and aluminum substructure.

It consists of mounting systems and a basic grid. Both consoles and stand are engineered exclusively for ventilated cladding, making this the first product on the market. All elements are designed in such a way as to provide ease of assembly of aluminum and the ability to adjust their position in three planes. All this avoids the problems associated with an uneven wall surface.

There are elements of the fixed supporting structure of the facade on the superstructure of the building and sliding ones, which allow other elements to cope with the expansion of the aluminum. The offer includes a number of different sizes and a special extension that allows it to be used in a wide range of dimensions.

Advantages of the aluminum frame:

- high strength;

- resistance to weathering;

- a light weight;

- low transport costs.

The absence of galvanic corrosion at the junction with other materials and the stamped production method prevent stress, microcracks and scratches that occur at the place of the cold bend.

Although the aluminum post is designed primarily for cladding, it can also be used with panels of the same material. There are two main types of T-bar mesh, which are used to connect slabs and corners and also as a retaining profile. The use of decorative elements can mask the visible edges of the plates or horizontal seams through which the substructure layer can be seen.

Beautiful examples in the exterior

Polyurethane foam is the most advanced material for insulating facades of buildings and structures. Panels with ceramic tiles act as effective thermal insulation and have a decorative function. The panel consists of two components: decorative outer side, insulation.

In modern architecture, there are many options for how you can transform the facade of a building with polyurethane slabs. A wide variety of colors, finishes and special effects provide a huge range of creative possibilities for creating the perfect façade.The unique cellular structure of the finishing systems ensures uniform diffusion of natural light and provides excellent thermal insulation, ensuring maximum resistance to impact and hail.

Building designers can hide various building elements or create intriguing visual contrasts by combining panels with conventional glazing. By jointly offering superior UV protection of the highest quality, façade systems guarantee a long service life for a building.

Insulated panels provide unlimited design possibilities by controlling humidity and reducing energy consumption. Modern manufacturers produce versatile, ventilated systems that accommodate a wide range of cladding options.

Recently, it has become popular to use slabs with a stone finish or various types of brickwork. Several types of such finishes look especially impressive among themselves, which make it possible to highlight several basic elements on the facade, including the corners and the foundation. An interesting design solution creates a unique and in its own way inimitable style of the building, conveys the special mood of the residents or adds respectability.

For information on the features of choosing front thermal panels, see the following video:

The comment was sent successfully.