Composite panels for the facade: features and applications

The well-known adage about what is met by dress applies not only to people, but also to buildings. Such a "dress" for them is a facade that performs an aesthetic and protective function. One of the variations in facade decoration is the design of the curtain system using composite panels.

Specifications

Composite panels include several dissimilar materials. As a result of this combination, facade panels are obtained that have absorbed the best technical properties of all the components used. The finishing option under consideration always consists of 2 main elements: a matrix (plastic layer) and a filler (reinforcing layer). In addition, composite panels have metal plates and a protective face layer.

Manufacturers produce materials that differ in size, color, filling and number of layers. However, all products are characterized by increased strength characteristics with low weight, weather resistance and long service life.

The panels are in the form of square or rectangular plates with a metal base. They are equipped with a heat-insulating layer. The front side is covered with a decorative layer that can have any shade, glossy or matte surface. Expensive products have a laminated surface that imitates a particular finishing material (wood, stone, brick).

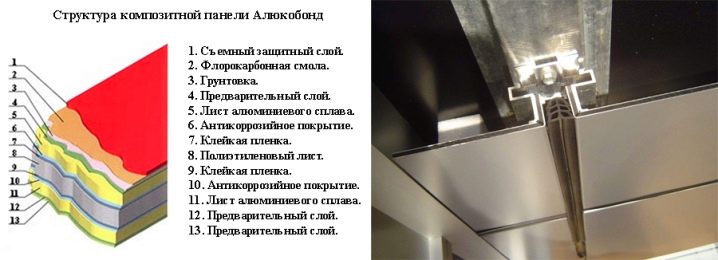

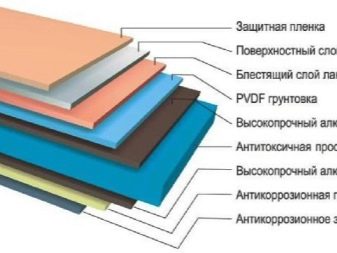

Any composite material is a multi-layer "cake" with the following structure (from the front to the inside of the panel):

- protective layer (ensures the preservation of the technical properties of the material, protects the color from fading);

- paintwork (responsible for the visual appeal of the panels);

- metal (usually aluminum) sheet (provides strength);

- glue layer (its task is to fix materials);

- filler (performs the function of reinforcement, providing the product with certain technical qualities);

- glue layer (it was already mentioned earlier);

- aluminum sheet (performs the function of strengthening, ensuring the reliability of the product);

- anti-corrosion coating (protects the metal plate from moisture, water vapor, condensation).

Panel sizes may vary. Length can be 240 mm, 320 mm or 400 mm, width - 100 or 150 cm. Panel thickness is 2-6 mm. Due to its low weight (8 kg / m2 kV), it is possible to avoid excessive load on the supporting elements of the building, which means that additional strengthening of the foundation can be dispensed with. At the same time, the multi-layer provides the strength and durability of the coating, as well as high thermal efficiency.

The operating temperature range of the panels is from -50 ° С to + 80 ° С. The panels are resistant to strong wind loads (squall wind) and corrosion. They are characterized by biostability and frost resistance.

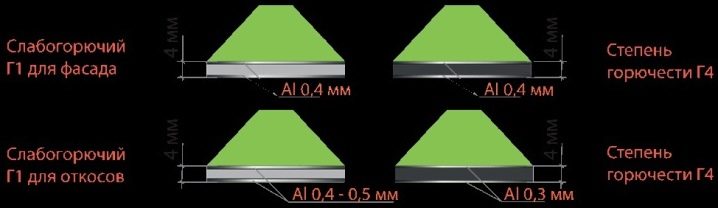

Composite boards are an excellent soundproofing material. With their help, you can halve the noise level in a house with concrete walls. The fire safety of the material is also at a height - it belongs to low-flammable, emits a small amount of smoke when burning.

Fire regulations allow the use of such materials for the decoration of private buildings and office buildings.

Advantages and disadvantages

Composite panels for facade cladding are lightweight, and therefore do not require additional strengthening of the load-bearing elements of the building, and are suitable for installation on high-rise buildings. Due to the plasticity of the material and its ability to bend, it is possible to finish any buildings, including those with a large number of architectural elements.

Walls finished with composite panels are characterized by impact resistance up to 50 kg / cm2. In combination with high weather resistance and resistance to thermal shock, this leads to a long service life of the panels. Depending on the type of product, the service life ranges from 10-25 years.

A wide operating temperature range, resistance to UV rays, as well as frost resistance make it possible to use composite panels in any climatic region. Improved indicators of moisture resistance of the material are also an obvious "plus", since moisture does not penetrate into its structure and does not reach the insulation and walls.

Fire safety of products is another significant advantage. Due to the high content of fire retardants in the composition and use of aluminum, it is possible to significantly reduce the fire hazard of a ventilated facade. By itself, it is considered hazardous in terms of the risk of fire, as the flame spreads rapidly through the air pockets. This is why it is so important to select fire-resistant finishing materials for such systems.

Installation of panels is quite simple, the material can be fastened even at low temperatures. However, experts do not recommend installing the crate at temperatures below 0 ° C. This can lead to a decrease in its reliability.

Thanks to the variety of colors and textures of the front part of the panel, it is possible to implement original design projects, to give the building a unique appearance. The use of panels imitating expensive wood or stone coatings helps to make the building more respectable.

Some types of tiles have a dirt-repellent coating and self-cleaning ability, which greatly simplifies their maintenance. As a rule, dust and dirt are washed off by rain. In rare cases, washing the facade with water using a soft sponge and a non-aggressive liquid detergent is required.

The "disadvantages" of materials are:

- high cost (prices for other facing materials, including expensive combined porcelain stoneware, are lower than the cost of composite plates);

- the material is not heat-insulating, therefore, to prevent the formation of cold bridges, it is recommended to use paronite or plastic thermal break gaskets;

- limited scope (restrictions are imposed by the flammability class of the material - it is not suitable for lining hospitals and childcare facilities, as well as the tendency to scratch the surface, which can spoil the lining of the building basement);

- low maintainability (if one panel is damaged, several adjacent ones will have to be dismantled);

- increased requirements for transportation, the need for careful handling during storage and installation (risk of damage to the front of the material).

Views

Depending on the type of composite, several types of panels are distinguished.

Mineral

The material contains foamed polyethylene, combined with a large number of various flame retardant additives. This provides the panels with low flammability. They belong to class G1 (slightly flammable material). When burning mineral plates, no corrosive smoke is released, the molten mass does not flow.

German-made products are distinguished by the presence of aluminum hydroxide in the composition, which makes them even more resistant to flame. The panels are used for exterior decoration of the house.

Polymer

They consist of polycarbonate and polyethylene foam, which results in a low weight of the material.This allows it to be used for cladding partitions, unreinforced structures with low bearing capacity. The main area of application is interior decoration of premises.

Aluminum

The composite is represented by thin aluminum plates that are assembled into a mesh. The material is characterized by high strength, high rigidity with minimal weight. Aluminum composite panels are not afraid of strong wind loads, which makes them the best option for outer cladding of high-rise buildings.

It is irrational to use them for finishing a private house, since tiles made of aluminum plates do not hold heat and are characterized by little sound absorption. Moreover, they are more expensive than their mineral counterparts.

Relatively recently, a wood-polymer version of panels has appeared, the basis of which is wood-chip flour. Due to the peculiarities of their composition, they are distinguished by greater heat resistance; in other parameters, they are not inferior to the varieties described above.

Composite panels also differ in the type of outer coating. There are several categories.

Polyester based paints and varnishes

The most affordable type of coverage. It is characterized by bright shades and glossy shine, well resists moisture, temperature changes, UV rays. Recommended for exterior decoration, but when used as a facade material, it becomes unusable after 5-6 years of operation.

PVDF paints, varnishes

Material for facade finishing, characterized by durability, the presence of a dirt-repellent coating, increased resistance to fading under the influence of sunlight. The average operational period is 20-25 years.

Oxide Films

The surface of the material has a mirror effect, which is explained by the electrochemical treatment of the aluminum included in the film. The material demonstrates improved weather resistance, corrosion resistance. It is operated without requiring repairs for 15-20 years. With its help, ventilated facades are usually created.

Laminating films

The most expensive, but also the most spectacular type of panels. The surface of the material imitates different types of expensive finishing coatings (stone, polished metal, wood). In addition, the material has high protective properties. The period of operation reaches 15-20 years. The most famous laminated boards are produced under the brand name Alucobond.

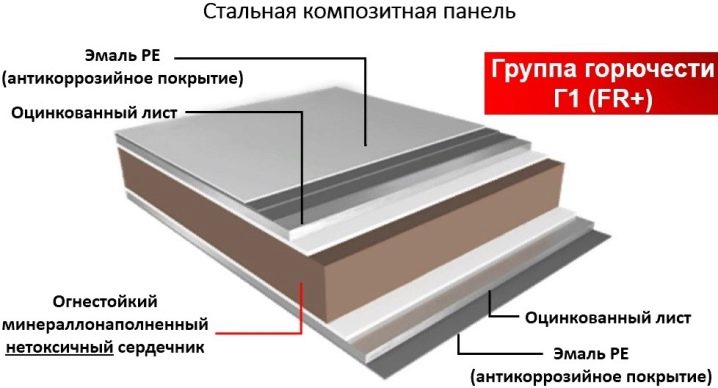

Depending on the type of metal used in the composite "pie", panels are distinguished:

- made of aluminum;

- made of galvanized steel.

The former have less weight, but the latter demonstrate better strength and higher melting rates. The latter characteristic speaks of their greater fire safety.

The colors of the composite panels correspond to the shades of the RAL catalog, which includes 213 colors, 17 of which are “metallic”. Colors are designated by a four-digit number, where the first number indicates the shade belongs to a particular color range. For example, if a color begins with the number 1, then it is one of the options for the yellow scale.

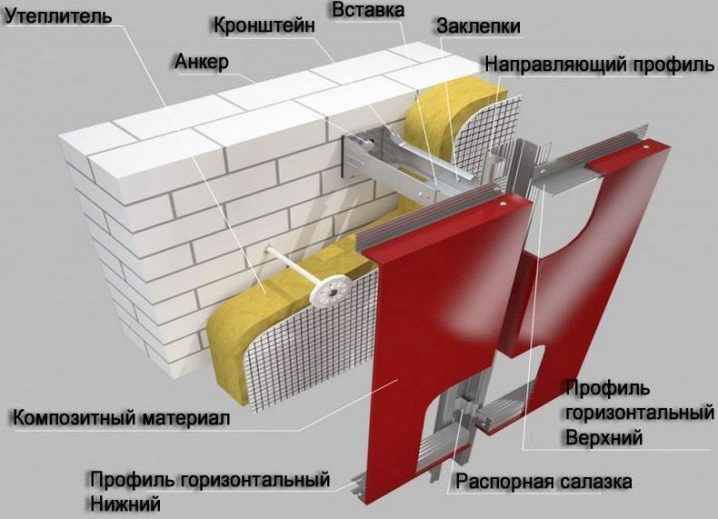

Subtleties of installation

Like any curtain wall, composite panels are installed on a frame made of metal profiles. In addition to the panels themselves, galvanized profiles are needed to create a subsystem, fastening brackets, self-tapping screws or rivets. In addition, you will need a drill and two-stage drills, a building level and a hammer drill.

You can cut the material with metal scissors, a circular saw or a hand jigsaw. It is also necessary to purchase thermal insulation material and a waterproof membrane, a primer or roller, thick markers or paint for marking.

First of all, it is necessary to draw up a project plan, draw up a drawing of the building in the selected scale. The design documentation should indicate the markup and the required amount of material.

The technology of installing hinged facades involves cleaning the walls, eliminating large cracks, and strengthening dilapidated elements. Minor defects can not be eliminated, because they will still be hidden by the casing. Prepared and clean walls should be treated with 2-3 coats of primer. For wooden surfaces, choose mixtures with antiseptics in the composition, for plastered ones - strengthening analogs of deep penetration.

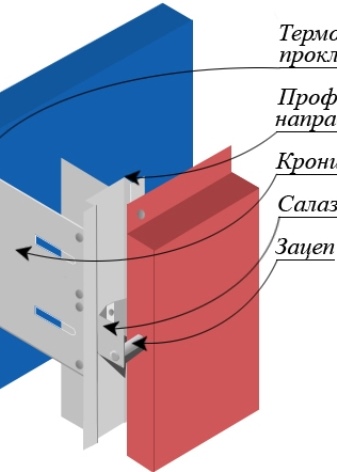

After the walls are completely dry, you can start installing the lathing. To do this, markings are made on the walls using a level and in strict accordance with the design documents. After that, according to the marking, it is necessary to make holes with a perforator, dust them and insert dowels. Then you can assemble the brackets and screw them into the surface.

At the next stage, insulation is mounted (usually mineral wool sheets). Experts recommend applying the sheets to the wall and marking the places where the brackets pass. Thanks to this, it is easy to make perforations for fasteners along the points using a construction knife.

Insulation with slots is applied to the wall, stringing it onto the brackets. Subsequent rows are stacked with an offset of half the sheet. In places of contact between the brackets and the wall, insulating paronite gaskets are used to prevent the formation of cold bridges. It is worth remembering that composite boards with a small heat-insulating gasket alone cannot act as an insulating material.

In the same way, a hydro-windproof membrane is laid on top of the insulating material. Its sheets are stacked with an overlap of 100 mm. After that, the insulation and the membrane are reinforced with a disc-type dowel for both materials. Suffice it 2-3 points of fixation on the sheet, one of which must be in the middle.

The frame device begins with the installation of a U-shaped profile. After that, spacer slides are fixed inside it, for which the cladding is attached.

Panels are attached to the finished frame. The first of them is aligned horizontally to the bottom edge of the crate. After that, the upper part in the corners is attached to the guide profile by means of self-tapping screws. Then, in the side part of the panel, closer to the upper part, a slide is moved (these elements are movable), to which the panel is fixed with self-tapping screws. You can move the slide with a screwdriver. Likewise, the slab is attached on the opposite side and below.

Install the rest of the panels. A gap of at least 12 mm is left between the elements. In the corners, panels are joined on each side, due to which a gap is maintained in each corner along the entire height. Another option for designing a corner is bending the panel with a bending machine, as a result of which the corner is smooth, rounded.

The production of panels is carried out with the application of a layer of polyethylene on its front side, which protects the material from damage during transportation and installation. After finishing the facade cladding, this film is removed.

If you need to cut the material, pay attention to the direction of the arrows, which are usually located on the back of the panels. They indicate in which direction to cut.

During cutting, the material should be placed on the table and secured. It is possible to drill aluminum panels only at low (500-800 rpm) speed, periodically cooling the drill.

When mounting, bending or sawing products, it is important that metal shavings or tools do not scratch the surface of the panel. Otherwise, it will reduce not only its aesthetic appeal, but also its operational characteristics. Bending damage to the face of the tile can be prevented by working on a perfectly clean surface.

Cladding examples

Depending on the color, composite panels make it possible to give facades a strict, businesslike or, on the contrary, a more casual and even "hooligan" appearance.

Experts recommend combining several shades of material within one facade to make it more voluminous, noticeable, and avoid monotony. It can be either a combination of 2-3 close tones, or contrasting options.

When combining laminated panels with colored counterparts, it is better to focus on the former.

In other words, if you have opted for a material "like a stone", it should be supplemented with a "companion" of a calm pastel, gray or brown shade.

Below is a detailed video instruction for the installation of composite panels.

The comment was sent successfully.