All About Diesel Welding Generators

Knowing about diesel welding generators can help you set up your work area correctly and ensure optimum performance. But first you have to study the nuances of specific models, as well as familiarize yourself with the basic selection criteria.

Peculiarities

A modern diesel welding generator is useful for work in areas where there is no stable power supply (or at least some kind of power supply). With the help of this device, you can equip water supply, sewerage, heating, gas and oil pipelines even in the most remote places. For obvious reasons, diesel welding generators are also useful in eliminating accidents, when working on a rotational basis. The current generation can also be used for emergency power supply. Therefore, such generators are also needed as emergency sources of energy.

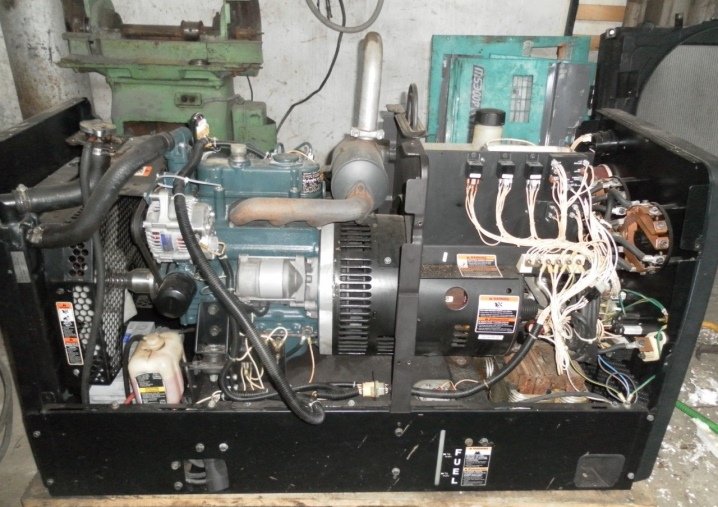

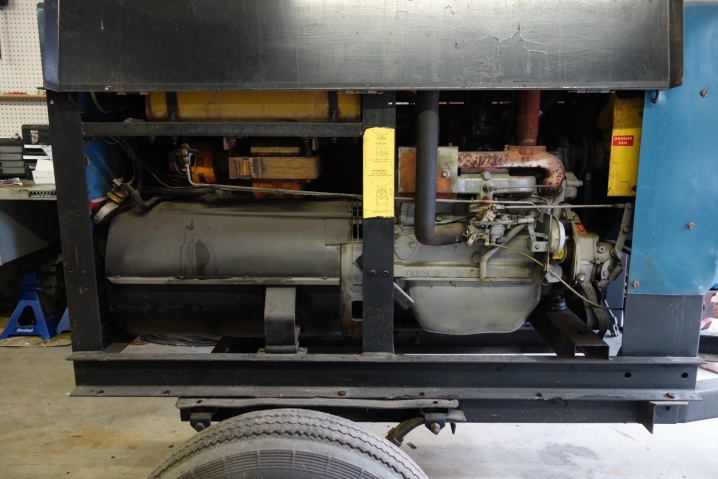

They are arranged relatively simply. There is an electric current generator driven by an internal combustion engine. They are mounted on one chassis. The connection of the two main units is made either directly or through a reducer. In some models, the generated current is fed to a step-down transformer. To compensate for the influence of various factors on the amperage (which determines the quality of welding), manufacturers offer inverter-type generators.

The bottom line is that diode rectifiers are installed at the output. The direct current is then additionally converted into a pulsed current (which already has a high frequency).

And only pulse discharges are fed to the step-down transformer. A direct current can be re-formed at the output. With all the advantages of such a solution, it obviously increases the cost of the structure.

Welding generators can be made according to a single-phase or three-phase scheme... In the first case, medium-sized devices are obtained that are useful in various workshops, in the course of ancillary work. Three-phase systems are needed when it is required to provide the work of several welders at once. Regardless of this, diesel machines are better than gasoline ones for long-term current generation. They are also characterized by increased efficiency and general practicality, much more reliable than carburetor generators.

Model overview

It is appropriate to start acquaintance with welding power plants with Miller Bobcat 250 DIESEL. The manufacturer positions its development as an excellent means of supplying current in the field. This model is also useful for working with metal structures, including on an industrial scale. It can be used to guide:

- fusible electrode welding;

- semi-automatic welding with flux-cored wire or in an inert gas atmosphere;

- air plasma cutting;

- argon arc welding with direct current.

Designers promise excellent seams on a wide variety of metals. The device is equipped with a maintenance indicator. There is a meter showing the diesel engine hours and the recommended interval before changing the lubricating oil. If the cooling system overheats, the generator will shut down automatically. Therefore, even a very intensive operation will not affect its working life.

The technical parameters are as follows:

- output voltage - from 208 to 460 V;

- welding voltage - 17-28 V;

- weight - 227 kg;

- total generator power - 9.5 kW;

- noise volume - no more than 75.5 dB;

- network frequency - 50 or 60 Hz;

- inverter three-phase design.

You can take a closer look at another product of the same brand - Miller Big Blue 450 Duo CST Tweco. It is a two-post generator optimized for:

- shipbuilding;

- other branches of heavy engineering;

- Maintenance;

- overhaul.

Alternatively, you can consider Europower EPS 400 DXE DC. Important: this is a very expensive device, its cost is about a million rubles.

But the power of the generated current reaches 21.6 kW. The internal volume of the combustion chamber is 1498 cubic meters. cm.

Other parameters are as follows:

- weight - 570 kg;

- voltage - 230 V;

- diameter of the welding wire (electrodes) - up to 6 mm;

- total power - 29.3 liters. with.;

- welding current range - from 300 to 400 A.

The next device is SDMO Weldarc 300TDE XL C... Maintenance and transportation of this welding generator is not too difficult. The device is suitable for long-term uninterrupted power supply. The manufacturer claims that the model works reliably for a long time. The quality of the output current is at the proper level, moreover, the designers took care of the safety of the operators.

Basic properties:

- total power - 6.4 kW;

- generator weight - 175 kg;

- diameter of electrodes (wire) - from 1.6 to 5 mm;

- welding current - from 40 to 300 A;

- electrical protection level - IP23.

There are also a number of other attractive devices. For example, a diesel generator LEEGA LDW180AR... It is also protected according to the IP23 standard. You can start generating current with a manual starter. The current range is from 50 to 180 A, while only direct current is generated.

The manufacturer guarantees that it will be possible to supply the instrument with current with the help of the generator. The parameters of such a power supply are 230 V and 50 Hz, as in a conventional city power grid. The tank can be filled with 12.5 liters of diesel fuel. When fully charged, current generation can continue for up to 8 hours in a row. Model:

- certified for compliance with Russian GOST;

- tested in the framework of the European CE regulation;

- received the TUV certificate (key industry regulation in Germany).

There is a trolley set. It includes a pair of handles and large wheels. The volume of the motor is 418 cubic meters. see The mass of the generator is 125 kg. It is compatible with the use of electrodes or wires with a diameter of 2-4 mm.

Criterias of choice

Choosing a diesel generator for welding, it is useful to pay attention first of all to its power. It is this property that determines whether it will be possible to organize certain works or they will constantly encounter difficulties.

The next important point is how much current the generator produces. There are models designed for direct or alternating current. Direct current is appreciated by specialists for its ability to weld very high quality seams.

Also, DC generators are used by builders who need to work with electrodes of various diameters. But alternating currents have their own advantages - they make the device simpler and easier to use. And the ability to power ordinary household equipment is very attractive.

However, one cannot count on particularly high-quality AC welding. To facilitate the initiation of the arc, it is best to provide a power reserve of at least 50%.

Another point is that cast iron lenses are better than aluminum parts. They allow you to increase the resource of the welding generator. If the inverter is purchased separately from the power source, PFC-marked models should be preferred. They work successfully even at reduced voltage. Important: you should carefully distinguish between power in kVA and kW, as well as nominal and limiting power.

It is also worth considering the following recommendations of experts:

- monitor the compliance of the generator power and the diameter of the electrodes used (indicated in the accompanying documents);

- give preference to the products of the same firms that produce inverters;

- consult with experts when purchasing generators for industrial facilities;

- take into account what equipment will be additionally connected to the generator.

How to choose a generator for a welding inverter, see below.

The comment was sent successfully.