DIY corner sofas

A corner sofa is always in demand. It is spacious and does not take up much space. It is not for nothing that such sofas are called family sofas, because you can accommodate the whole family on it. Hand-made furniture is relevant today, and sofas are no exception.

Pros of self-manufacturing

Originality of execution and independent choice of shapes and colors are the main advantages of self-production. At the same time, you control the price range yourself, choosing material for your wallet. Another plus is quality control. Everything depends only on you, and therefore there is no risk of being deceived.

The most pleasant thing is aesthetic pleasure and a sense of pride in the work done. The delight of others and respectful views of your brainchild will only strengthen this state. Therefore, you can safely take on the implementation of the sofa for the comfort and coziness of your home.

Material selection

The choice of material should be taken very seriously, you need to think over the arrangement of the sofa in advance. Having compiled a detailed list of everything you need, you can go to the hardware store. The thickness and amount of everything you need will depend only on your preferences and wishes.

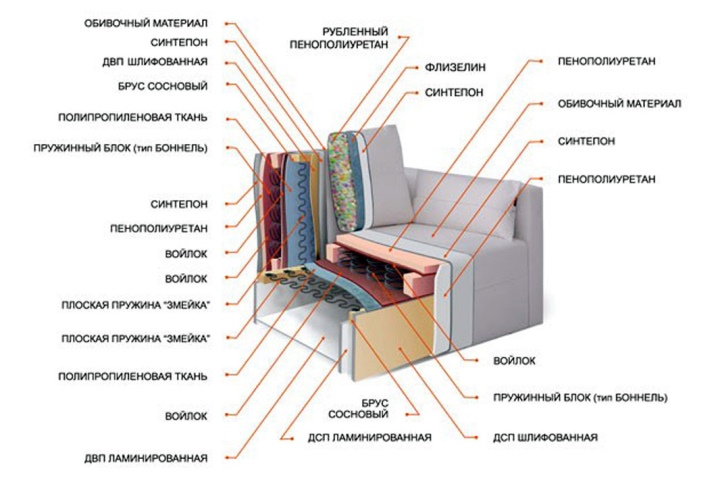

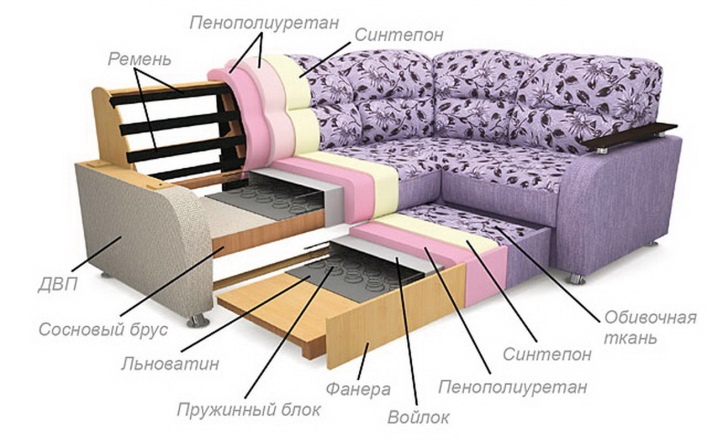

The base of the sofa is most often made of wood, coniferous timber. Usually, preference is given to pine timber, as it is stronger than its "brothers". The following important materials can be distinguished:

- Fiberboard - the bottom for the sofa and drawers.

- Chipboard - laminated, serves for the furniture board (the base of the sofa and armrests).

- Plywood - covering for the frame of the sofa. Birch is considered the best.

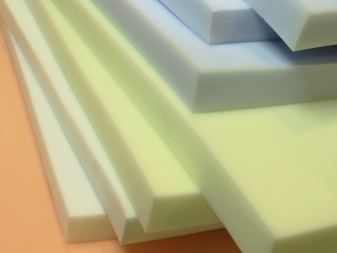

- Foam rubber, synthetic winterizer - materials for padding the back of the sofa, pillows.

- Upholstery fabric is a decorative part of the sofa that serves to stretch and create the final image.

- Fasteners - screws, self-tapping screws, corners, nails and everything with which the elements will be assembled.

- Retractable mechanism - type of mechanism, the choice depends on your desire, as well as on skills.

- Furniture legs - can be stable or on casters.

- Glue, threads - useful when connecting pieces of foam rubber and working on the waist.

Required tools

So, you will need to prepare the following:

- Screwdriver with different attachments - for screwing in fasteners or making holes.

- Circular saw - for cutting large items that require precision (or jigsaw).

- A hacksaw (hand saw) and a miter box - for cutting precise angles.

- Foam knife and fabric scissors.

- A sewing machine - for a cover and a constriction.

- Furniture stapler - for fixing the matter.

- Twine or twine - to give an interesting shape to the back and various elements.

How to make a model yourself at home?

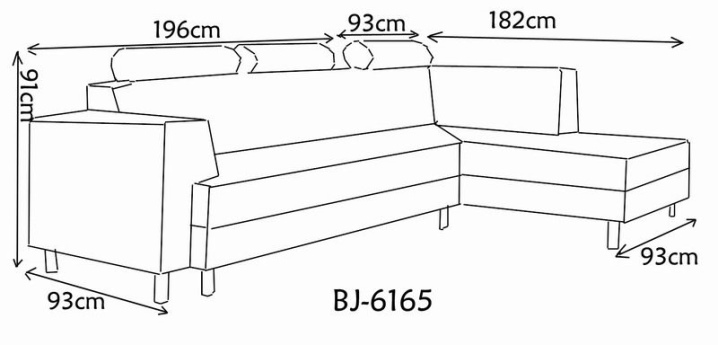

So preparation is needed. To make a sofa, you need to make a drawing with all dimensions and elements. If you have problems with slicing, you can order it from the store where the materials will be purchased.

Number all the details (in accordance with the drawing) and carefully arrange everything according to importance: the most necessary - on top or next to it, then - smaller elements. It is important to start assembly with large parts, then you need to gradually "build up" on the frame everything else. Fasteners can only be screws. For durability, you can first glue and then fix the result with screws.

Manufacturing.

Given the fact that the sofa is angular, you should not confuse the details of the short and long sides. Execution order:

- First, set up two sidewalls and use fasteners to connect them to the horizontal bar and vertical posts. There should be at least four attachment points for each rack. The frame of one side is ready. Now it needs to be sheathed. A sheet of plywood is attached to the top of the frame. Chipboard must be attached to the back.

- Next, you need to go to the assembly of the second part - short. There will also be a laundry box here. On the sides, you need to attach longitudinal transverse bars. Sheathe the finished frame and seat with chipboard and plywood. Close the bottom of the fiberboard.

- If the drawer is removable, then it can be made of fiberboard. For the hoist, drill the bolt holes and secure.

- The armrests for the sofa can be removable, fabric or linked to the frame. To do this, screw a bar that repeats the shape of the armrest to the frame. All this is sheathed with chipboard.

- If the armrests are of an unusual shape, with bends, then use fiberboard and a lot of small nails. Sharp edges need to be smoothed out so that the sheathing does not wear out.

- Glue the finished wooden structure with foam rubber - for the seats, take solid dense pieces on the left and right parts, and the back can be made a prefabricated one, from several elements. The recommended foam rubber thickness is over 100 millimeters. If there is no such thickness, then thin elements can be glued together.

- If you want to make an interesting backrest with bends, then use twine and the remains of foam rubber pieces, giving a beautiful shape. For armrests, it is better to use batting. At this stage, the assembly of the base is completed.

- Move on to the upholstery. So that the fabric does not wear out, the foam rubber does not wear out, it is better to tighten with agrotextile between them. For constriction, choose dense, wear-resistant fabrics - tapestry, thermohacquard or chenille.

- For accuracy and beauty, a pattern or pattern is needed. You can also hold the fabric against the couch and chalk out where to cut. In this case, do not forget to leave the fabric for allowances - 2-3 centimeters each. When cutting out the back, take into account its shape, creating the appropriate elements. Padding can be with stitched elements.

- Use twine and a stapler to create the back bumps. In the back, make holes for tension in advance. Draw a loop into the holes - and it is to it that you attach the twine.

- When doing upholstery, make sure the tension is even. The drawing must match. To make your work easier, use plain fabrics or designs that don't require precision.

If you are a lover of soft sofas, then you can sew pillows to size and add to the frame. If necessary, they can be simply removed.

We do it on the balcony or in the gazebo

With a corner sofa on the balcony and in the gazebo, you are assured of comfort. On warm summer evenings it will be very pleasant to get together with the whole family or invite friends.

Such a sofa can be created from ordinary and familiar pallets. Another name is pallets.

All work consists in building the necessary structure of boxes and fixing them. However, for aesthetics, you need to pre-process the pallets in any convenient and suitable way for the interior - grinding, painting, varnishing, creating an aging or gloss effect, decoupage, drawing. Anything that comes to mind will do and will be combined with the fabric.

Then you will need to make a seat. Stack several pallets on top of each other until you reach the required height and length. Fasten them together with self-tapping screws. You can put solid sheets of plywood between the drawers and get additional shelves for storing things.

Then you should tackle the back. Place the pallets vertically in relation to the seat so that the letter “L” is created.

Sheathe the resulting frame with plywood or chipboard sheets. Then you can glue the elements with foam rubber or make removable seats - without attaching plywood to pallets, sheathe it with foam rubber and fabric. If necessary, they can be simply removed.Next, sew the necessary elements - pillows of different sizes, armrests. For a gazebo, such sofas are relevant; in rainy weather and in the cold season, pillows can be removed.

A corner sofa is a godsend for a large family and a small space. It creates an atmosphere of comfort in any room - be it an apartment or a gazebo. Thanks to the large seating area, it can serve as both a bed and a resting place for a large company.

Below is a video that will help you quickly and easily assemble a corner sofa frame.

The comment was sent successfully.