How to make a bunk bed for children with your own hands?

Handicraft has recently become more and more appreciated and gaining popularity due to the non-standard solutions used. This also applies to furniture. Quite a time-consuming process that requires patience and some skills, in the end it can please even a beginner with its results. There are many ideas for creating a wide variety of garden furniture, including wooden pallet sofas. An equally atypical approach can also be implemented in the manufacture of home furniture. In this article, we will tell you how to easily make a two-tier bed on your own.

Why is handmade furniture good?

A self-made bed is always better than a store bought one. And there are many reasons for this. First of all, the quality of the material used in the work. Choosing it, any master will take into account such parameters as reliability and durability. Therefore, at the end of the work, he will have the confidence that his product will last long enough and will not disappoint with its durability the first time it is used. It happens that in the store it is impossible to find the right thing. For furniture, this situation is especially relevant: the size of the object may not be suitable, you may not like the design or the types of materials used for the frame and finishes. The question arises as to which is better: to order an individual production of a thing or to take on the work yourself. Sometimes the choice of the second option is preferable, because in this case there is no need to search for a good master, explain to him your ideas and pay a considerable amount for the work. But the main advantage of any hand-made thing, of course, is the special feeling both during work and in the process of using the product - it is always nice to feel like a creator.

Let's summarize. By creating home furniture with your own hands, you can win on several points:

- price;

- quality characteristics of the materials used;

- unique design;

- individual parameters of the product.

Varieties

The scheme for making such a bed is not very complicated. Such a bunk bed and ladder can be made of different materials, for example, plywood or chipboard. Also, do not forget about the decor and stylish curtains in the project. If you have already made the decision that you need to do the bunk bed yourself, then you can start doing the work. However, you first need to understand the many existing models of bunk beds, considering the most popular ones.

Classic

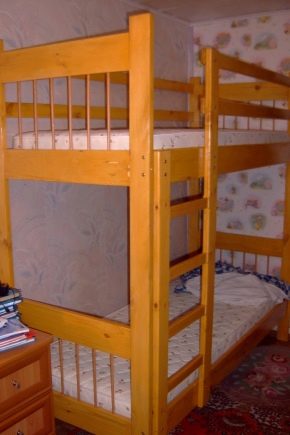

It is as easy as shelling pears to make it. The design of the product includes two sleeping places, located at different levels from the floor. There is also a side staircase. Usually, such a model is placed in large children's rooms as furniture.

With sofa

The presence of a sofa part located on the first "floor" is an excellent solution from a functional and aesthetic point of view. Such a model can be placed in a room of almost any size, and it will be used by households not only as a bed, but also as a cozy place for leisure and relaxation. It would be quite appropriate to place such a convenient structure in one of the corners of the living room.

With functional details

In order to maximize the ergonomic use of the area of a small room, you can fill the space formed under the stairs to accommodate various household items. The size of such a bunk bed is usually much larger than that of the classic version, but the efficiency is higher.

Attic

Great construction for a small nursery. The second floor is a classic sleeping place, while the first is used as a study. It accommodates a desk, shelving and planning the right lighting. Such a model can appeal to adult children seeking to have an individual space. It is usually made one-bed, although if necessary, larger sizes can be provided (taking into account the accommodation of two people). This bed has a variety of location options: traditional or in the corner of the room. The main thing is to provide for the strength characteristics of such a product.

Bunk triple bed

To make the traditional model a three-bedroom model, use a little trick. For example, if there are kids in the house and the living space is limited by the framework of a small room, it is logical to place a double place below. If the bed is made for a child, then the sleeping place is located at the top.

Convenient transformer

A very popular model with an extremely ergonomic design. Usually, in addition to the bedroom, it includes a disassembled place in the form of a sofa or table. Individual elements are made collapsible or retractable, for example, a table.

What materials are used for the frame?

There are a lot of types of wood suitable for making a bed.

Let's consider the main ones.

- Non-glued board (array). This material is very expensive and difficult to use in manual work by beginners and requires special preliminary preparation. It is best to have some experience to work with an array. The advantages of using it are that the manufactured products serve for a long time and are beautiful. Given that children grow quickly, this requires a revision of the issue of their placement, therefore it is very uneconomical to use expensive material for the manufacture of their furniture.

- Sliced board, timber, edged board - the most common materials in the manufacture of furniture, characterized by ease of use. When selecting them, it is only important to take into account the quality of drying in order to exclude constructive violations in an already finished product.

- Finely dispersed wood fraction in the form of a board (MDF). Quite safe material with the same formaldehyde emissions as the first two types of materials. The peculiarities of working with MDF include the fact that when drilling it does not form sawdust, but dust. Usually MDF sheets are laminated to give an aesthetic appearance. If you use MDF without decoration, then you must at least varnish them. As a rule, cutting of parts from this material is ordered in workshops where special sawing equipment is available. Craftsmen can also glue the edges at the cut points.

- Wood shavings board (chipboard). Since the emission of formaldehyde in such a material is increased, with the exception of E1 class boards, the products require an airtight coating. Features of use: the material is easy to cut, but absolutely does not hold the fasteners. It is best used in the manufacture of lightweight structural elements that will not be loaded. Chipboard, pre-coated with laminate, is suitable for the manufacture of backs and finishing panels.

Required tools

If the master made the decision to entrust the cutting of materials according to the drawings and measurements to the professionals of furniture business, then not so many tools are needed for the work. And at the end of the cut, the main task will only be to assemble the bed.

This operation requires the following tools and parts:

- screws;

- screwdriver;

- level;

- glue;

- hammer;

- drill;

- Grinder;

- already sawn parts of the product.

Completing of the work

If the preparatory phase is completed, it's time to start assembling the bunk bed.

- The foundation. First, a frame is built, that is, a rectangular box in which the mattress will fit.

- Tsargi. The base of a bunk bed is made from sawn to size and then polished parts. A smaller board width is attached to them perpendicularly. Thus, it turns out something like a shelf.

- Bricks. They are attached with self-tapping screws to the drawers. Planks are laid out between them, which will hold the mattress.

- Strengthening the frame. On the short sides of the bed, it is also necessary to make shelves on the inside of the resulting rectangular structure. For this, the boards connected by a shelf are attached to the tsars with self-tapping screws using a secret fastening method.

- Boards that are laid out between the drawersmust be strong to support sufficient weight.

- Installation of backs. The backrests are attached to the uprights. Their width is usually equal to the width of the bed. There should be three backs: at the feet, at the head and at the part of the bed that will stand against the wall. For fastening these elements, dowels are used - these are wooden blocks of circular cross-section, their diameter is determined by the thickness of the drill. Having drilled holes of the required diameter in the backrest and uprights, dowels are placed in them.

- The bed of the second floor is made in the same way. Then a ladder is attached to the supporting post. They also construct additional backrests as a fence on the upper floor. If the design features of the product suggest the presence of storage places under the stairs, then it is attached to the outside of the rack.

Finishing

The decorative design of the bed must be provided even at the design stage, since it can affect the sequence of stages of work. Experienced craftsmen make beds of bizarre shapes and taking into account the wishes of the baby: like a hut, a car, a boat. The ladder is sometimes replaced by "vines", climbing up which the child will imagine himself as Mowgli. And an experienced carpenter will make a bed in the shape of a fabulous home from your favorite children's books.

Additional elements can also be added to the bed, such as wall bars, rings, rock-climbing panels. Slides in the form of slides from playgrounds are very popular design details. A master with imagination is capable of embodying any design of a bed for a child, as well as finishing and decorating its panels. But you can also decorate the product with textile trinkets: pillows, pendants, ropes. Making your own bed in two tiers is generally easy. And the advantages of such work can be cost benefits, individual style and the joy of household members.

We can only wish you success in this interesting creative process!

For information on how to make a bunk bed for children with your own hands, see the next video.

The comment was sent successfully.