Cement slurry proportions: ratio and consumption

Cement is the main building material used in almost all sectors of the national economy. With the help of this substance, very strong products can be obtained that can withstand high loads and withstand external influences. But all these characteristics also depend on the components used and the cooking technology. Cement mortars are widely used in construction, as they can simplify many operations.

Peculiarities

Cement slurries are artificial mixtures that, after hardening, form a strong structure. A similar product consists of several main components.

- Sand. It is used as the main component because it combines fine structure and relatively high strength. For the preparation of solutions, river or quarry sand can be used. The first type of material is used in monolithic construction, making it possible to obtain very durable products.

- Water... This component is needed to bind sand and cement. The amount of liquid is selected depending on the brand and purpose of the solution.

- Cement. It is a basic substance that adheres well to other materials. Today there are several brands of cement designed for use in different conditions. They differ in strength indicators.

- Plasticizers. Technically, these are various types of impurities that are intended to change the physical or chemical properties of a solution. They are not used as often as they can add significant value to the product.

Such products are used to solve the following types of tasks:

- plastering - walls are covered with some solutions to protect the building material, as well as to level the base;

- masonry - cement mixtures perfectly bind a brick or aerated block together, therefore they are used as a kind of glue located inside each seam;

- creation of reinforced concrete structures.

Formulation types and requirements

The main characteristic of a cement slurry is its strength. It is due to the ratio of cement and sand. The composition of the product can be changed per piece, which makes it possible to obtain several types of mixtures. Each of them is intended to be used in a specific environment. Therefore, it is important to properly prepare products during the construction of various facilities.

Types

One of the criteria for dividing cement mixtures into types is the proportions of internal components. It is worth noting that only one brand of cement can be present in one composition. But they can also change, since the strength will depend only on the concentration of the components. They are conventionally divided into several brands.

- M100 (M150) - these mixtures are characterized by low strength. For their preparation, you can use cement grades M200 – M500. But at the same time, it is necessary to correctly select the proportions of the cement-sand components.

- M200 - This is one of the most common types of solutions. It is used very often in everyday life for the construction of paths and or the formation of coatings that do not lend themselves to significant loads.This mixture dries relatively quickly, but at the same time it requires compliance with certain microclimatic conditions.

- M300 - this type of solution can already be attributed to concrete types. It is used to prepare concrete, from which strong floor slabs are then made, foundations are poured and much more.

- M400 - it is durable concrete, which consists of high-quality brands of cement (M350, M400, M500). It is used in the construction of foundations for multi-storey buildings. This solution forms the basis for the manufacture of reinforced concrete floor slabs and other similar products.

- M500 Is the most durable concrete that can withstand very high loads. It retains its original properties for many years and under the influence of various irritants.

Additives

The quality of the cement slurry depends on almost all of its components that are present inside. Sometimes the properties of a sand-cement mixture are not enough, so you need to adapt them to certain conditions.

This problem is solved by adding various impurities to the composition. With the help of such additives, the so-called liquid glass is obtained. These products are used for plastering walls and other surfaces.

Several products are used today as cement mortar additives.

- Lime... Only its quenched types are used as additives. The introduction of this substance allows you to slightly increase vapor permeability and strength. But in order to prepare such products, you must observe the exact proportions. Very often plasters are made on the basis of lime, which are perfectly applied to the walls.

- PVA... The glue improves the adhesion and plasticity of the mortar. It is important to choose the correct concentration of the additive in order to obtain a good mixture.

- Detergents... Such products affect the plasticity of the solution. They are added to the composition only after water. Here, too, the exact dose of the impurity per unit volume must be observed.

- Carbon black or graphite. These substances practically do not affect the physical properties of the mixture. They are used only as dyes to change the color of the finished product.

Sand to cement ratio

You can even prepare a cement-sand mortar at home, since it consists of available components. It is quite easy to get them in almost any hardware store. But the solutions differ in the ratio of cement and sand, on which the consumption and physical characteristics of the material depend.

Brickwork

Bonding bricks is one of the main tasks of cement mortars. For such purposes, not particularly strong brands are used (up to M400). To obtain such a mixture, experts recommend using medium-fraction sand with a minimum moisture level. Masonry mortar can be prepared using various brands of cement. But this will already change the ratio of cement and sand. Some proportions are presented in table 1.

Table 1. Ratios of components depending on the brand of cement

Cement brand | Part of the sand | Part of cement | Lime |

M500 (without lime) | 3 | 1 | - |

М400 (without lime) | 2,5 | 1 | - |

M300 | 3,5 | 1 | 2/10 |

M400 | 2,5-4 | 1 | 1,3/10 |

M500 | 3 | 1 | 2/10 |

Please note that it is advisable to calculate according to only one measurement unit. In most cases, all parts are calculated for 1 m³. But at the same time, the masses of various materials in a cube may differ.

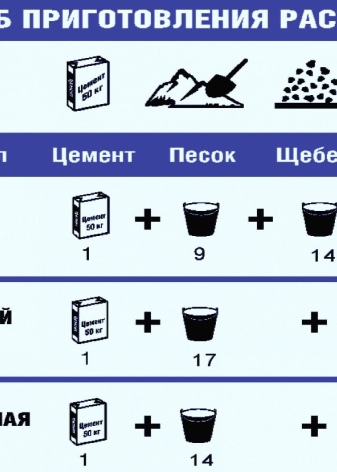

Concrete preparation

Concrete structures are also very commonly used in modern industry. These materials are manufactured in factories or directly on construction sites. The strength of such products also depends on the cement to be used. Technically, concrete can also be made from M100 grade mortar, but it will not withstand loads and have a minimum service life.

Another feature of concretes is the presence of crushed stone and other auxiliary components in the composition.They are introduced with the aim of changing the technical characteristics of a product.

It should be noted that they can be mixed in various combinations, depending on the environment in which the concrete is used.

Today, many specialists use such a ratio of the components of concrete solutions as:

- 4 pieces of rubble;

- 1 part cement;

- 2 pieces of sand;

- ½ part water.

Please note that the proportions may change if you plan to use different polymer additives. In such cases, it is advisable to pay attention to the recommendations of the manufacturers of these impurities.

For plaster and screed

Floor filling very often involves the use of relatively liquid cement mortars. This consistency allows you to evenly distribute the mixture on the substrate and obtain a horizontal surface. Plaster, on the other hand, almost always consists only of pure sand, cement and water. Its density can be different, since it all depends on where it is planned to be used.

The most common proportion for producing plaster mixes is the ratio of cement to sand 1: 5. The consistency is adapted to the needs of the master.

Particular attention should be paid to screeds that lend themselves to significant and constant stress. For such surfaces, materials with a threshold strength of at least 10 MPa should be used. This is achieved through the use of concretes of a grade not lower than M150. The proportion of preparation of the screed solution depends on the following factors:

- using mixtures to hide various communication elements;

- surface leveling thickness. If you just need to strengthen the floor with small differences, then use more liquid formulations. For thicker layers, it is advisable to use strong types of mortars.

Table 2. Proportions of sand and cement in screeds

Solution grade (result) | Cement grade | Quantity of cement (parts) | Amount of sand (parts) |

M100 | M200 | 1 | 3 |

M150 | M300 | 1 | 2 |

M200 | M300 | 1 | 1 |

M150 | M400 | 1 | 3 |

M200 | M400 | 1 | 2 |

M300 | M300 | 1 | 1 |

Please note that the proportions of the components are the same in most cases. But at the same time, the strength of the resulting solution at the exit is different. This is important to consider if the products will be used in specific operating conditions.

How to dilute correctly?

The process of preparing cement slurries involves mixing all components in a specific sequence. A similar procedure can be described in several sequential steps.

- First of all, you need to decide on the type of solution that you need. At the same time, attention is paid to the strength of the resulting mixture. If this indicator is important, an additional calculation of all components should be carried out. Particular attention should be paid to norms or standards.

- At this stage, dry components are mixed, the volume of which is measured in 1 m³ or other similar units. Before mixing the mortar, mix the sand and cement thoroughly to obtain an even mixture. Therefore, it is so important to use dry substances.

- When the preparation is successful, you can dilute the mixture. To do this, gradually add water to it and thoroughly mix all the components. It is best to use concrete mixers or other mechanical devices. The consistency of the mortar is adjusted with a liquid.

Tips & Tricks

Grouting is a simple operation. In its implementation, it is still recommended to follow a few simple rules recommended by the manufacturer and experienced builders, such as:

- if the mixture must be plastic, for this you need to add liquid soap to it. It must be mixed with water first;

- add water in small portions. Thus, you can control the density of the mixture, which is very important for screeds or masonry;

- during construction, it is imperative to take into account the brand of the brick itself or other material.Experts recommend preparing such mixtures that, according to these parameters, should coincide. This will allow you to get a homogeneous structure of the wall, which will differ in strength;

- to increase the thermal insulation characteristics of plasters, it is worth adding perlite to their composition. In this case, they need to replace a certain part of the sand;

- it is recommended to use only fresh cement, the structure of which does not contain lumps. This guarantees high adhesion and uniform mixing.

Cement slurry is an excellent material for strong structures. A properly prepared mixture is the key to the durability of almost any structure and its base.

You will learn more about the proportions of the cement slurry in the following video.

Liquid soap is not allowed. It degrades the brand very much. For plasticity, you need to add special additives.

The comment was sent successfully.