All about asbestos-cement mixture

On the modern market there is a large selection of various ready-made mixtures for finishing. Professional builders prefer to prepare such solutions on their own.

When decorating internal and external walls, an asbestos-cement mixture is used. It can be prepared not only on the basis of cement, but also sand, and even clay, the main thing is to know the proportions. Depending on the composition, it can set faster or slower. Sometimes asbestos-cement mortar is used for finishing stoves, as it retains heat well.

Properties

The asbestos-cement mixture has a number of positive characteristics, which is why it is so often used in construction. The mortar is plastic, has good tensile strength.

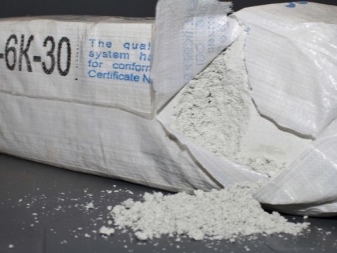

Asbestos paste is durable and versatile. Supplied in bags, dry. To create a solution, you need to use water.

Such a cement coating is durable, resistant to subzero temperatures, waterproof and does not support combustion.

Composition

The asbestos-cement mixture contains 70% of cement, and you should choose a material grade of at least 400. The fiber itself is only 30%. Water is added in the amount of 10% by weight of the mixture. This is how GOST regulates.

The composition may contain gypsum, lime, clay.

The composition varies depending on which walls (internal or external) are finished.

Internal walls

Lime

For this mixture, take lime dough and sand, which can be from 1 to 5 parts. When adding water, everything is thoroughly mixed. To avoid lumps, sand is added gradually. The overall consistency should be close to that of the dough.

The mixture is prepared exclusively for the day.

Lime-gypsum

In addition to the previously listed components, gypsum is used. First, a plaster dough is prepared. It is not difficult to do it, just pour the dry mixture into the water, stirring. Then the resulting product is mixed with lime dough until a homogeneous mass is obtained.

Portions should be small, as the composition sets quickly.

If you overdo it with water, then the solution will dry longer, and the coating itself will be loose as a result.

Cement-lime

Take for cooking:

- cement;

- lime;

- sand.

At the first stage, sand and cement are combined, only after that lime paste is poured. The proportions are 1: 1: 10, where cement, lime and sand go in order.

Facade

The sand is pre-sieved. The cleaner it is, the better the finish. Cement grade 400 is taken, added in a ratio of 1: 4, where 4 parts are sand. If M500 is used, then the proportion also changes - 1: 5. If you do not comply with the requirement, you get a fragile solution.

During the manufacture, dry components are mixed and only then water is added.

The ideal result is the consistency of thick sour cream.

Lime

In some cases, lime is substituted for cement. This does not affect the quality of the finished product. Only slaked lime without lumps is used. First, sand is placed on the bottom, then water is added and only after that lime.

Clay

This mixture is made using cement, sand and lime. Only with them does the material become suitable for facade decoration. Some add gypsum.

The clay is pre-soaked in water. On average, this process takes up to 3 hours. To prevent the clay from drying out, you need to add water.When it acquires the thickness of sour cream, you can use it.

Now it's time to add 0.2 parts of cement. Mix everything and add a little sand. For 1 serving of clay, you must put 0.3 parts of lime, which is used instead of sand.

Application

Asbestos-cement mortar is used as insulation on walls and not only. Thanks to such a crust, it is possible to retain heat. It is not susceptible to moisture. Asbestos fibers make the surface smooth, and if you plaster the wall afterwards, cracks will not appear.

Rarely, but it happens that asbestos mortar is used for thermal insulation of a pipeline or ventilation duct. This mixture has a high asbestos content. The composition is used, if necessary, to strengthen the joints between pipes made of the same asbestos.

Among other things, the solution can be used as a filler when laying socket pipes. Thanks to him, the joints have greater elasticity.

Internal and external walls can also be covered with asbestos-cement mortar. It is also used for stoves.

Preparation

Asbestos cement can be made by hand if you know the proportions. For the oven used:

- gypsum powder;

- clay;

- asbestos.

Sometimes sand or fiberglass is used as a filler.

If gypsum is used as the main raw material, then in combination with fiberglass, lime and sand, the ratio should be 1: 0.2: 2: 1.

Clay can also be the main filler, then it is applied with sand in half. The fat content of the clay plays an important role. The resulting mixture must be viscous, otherwise it will be inconvenient for it to plaster the walls.

Clay solution can be of the following types:

- asbestos, sand, clay - 0.1: 2: 1;

- cement, clay, asbestos, sand - 1: 1: 0.1: 2;

- lime, asbestos, clay, sand - 1: 0.1: 1: 2.

Any mixture of asbestos and cement is a durable, unique finishing material. It was used to make such products as pipes and slate 20 years ago.

Durability and reliability - this is what distinguishes the mortar with asbestos in the first place.

You can learn how to mix concrete mixtures correctly in the video below.

The comment was sent successfully.