Insulated cabins: characteristics and requirements

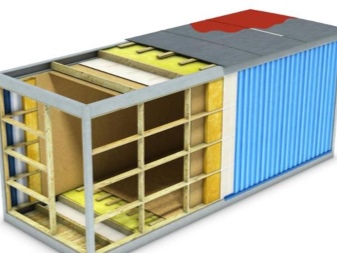

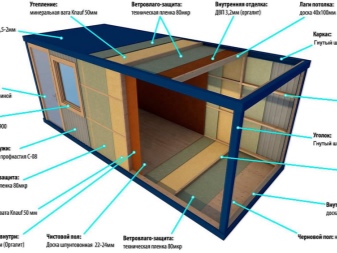

Change houses are divided into 3 main types. We are talking about metal, wood and combined rooms. However, if it is planned to make them residential, it is necessary that it is warm and comfortable inside. It should be borne in mind that when choosing a heater, you should pay attention to what material the frame is made of, and take into account its technical characteristics.

Insulation materials

An insulated change house can be an excellent option for winter living. The range of its functions and tasks will expand significantly. Therefore, this issue is very important. The choice of material for insulation is becoming one of the main points. It should be noted that today there are no problems with the range of materials on the market. However, the most popular options should be considered.

Styrofoam

This insulation is used mainly when equipping the walls of utility rooms. Its use is especially important when working with wooden cabins. This material tolerates moisture well. There are no difficulties with its installation. However, there are also disadvantages in this case. First of all, they include rather short service life.

In addition, in order for the thermal insulation to be of really high quality, the material must be used in large quantities. Its poor quality can lead to serious heat loss. It should also be borne in mind that foam, applied in several layers, will significantly reduce the internal area of the change house.

Mineral wool and fiberglass

Unlike the previous version, these heaters differ in fire safety. If you place them correctly, thermal insulation properties will be at their best. If placed in multiple layers, acoustics will increase. However, experts recommend choosing this insulation with caution. The fact is that a number of components in the composition can be harmful to human health.

Basalt slabs

The basis of the material is made up of basalt rocks, which have undergone careful processing. In construction, slabs are most often used, which are easy to cut into the desired parts, and also easy to install. The insulation is fire resistant. He is able to maintain his shape for a long time. The material is quite compact, so it will not reduce the area of the room in which it is located. However, when installing it, it is inevitable a significant number of seams, some consumers consider this a disadvantage.

Polyurethane foam

If you plan to insulate a utility structure, users often choose polyurethane foam. It can be either hard or liquid. In order to increase the heat capacity of the exterior finish, it is advisable to use a hard one. It becomes an excellent heat insulator for walls and roofs. In addition, it also becomes possible to mask some of the defects made during the construction process.

Polyurethane foam can also be sprayed onto surfaces inside a structure. This helps to fill any openings that cold air can enter, which serves excellent thermal insulation.

When installing it, no clamps are needed, and no seams are formed. The material is environmentally friendly, resistant to mechanical stress. If you do not make gross errors in operation, it can serve for more than 30 years.

Requirements

The main function of the material is to make the room temperature comfortable for year-round use. Accordingly, certain requirements are imposed on it. Even at high temperatures, it is necessary to exclude the possibility that the insulation will catch fire with an open flame. It must be compatible with the framework. The wear-resistant qualities of the material must be at a high level in order to ensure a long service life.

In addition, if it is planned that the premises will be intended for permanent housing, the products must be completely safe for people, their life and health.

Do-it-yourself insulation

In some cases, the procedure can be carried out independently. No special skills are required for this; even a person who has nothing to do with construction can fix the insulation. However, the main subtleties should be considered.

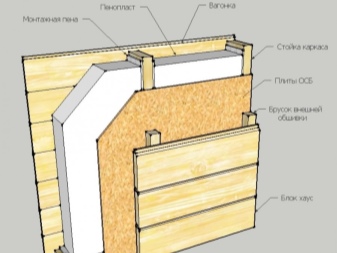

Thermal insulation outside

The sequence of work is very important, because it depends on it whether the insulation will go well, and whether additional costs will be required. As for the outer part, first of all, strengthen vapor barrier... This can be plastic wrap, foil, and other materials. The main condition is facade ventilation. On an excessively smooth surface, you can fix the slats vertically, they will hold the material for vapor barrier.

Next, the insulation itself is mounted directly... Most often, the choice is made in favor of mineral wool or fiberglass. To reliably protect the room from the cold, it is enough to lay the material in 2 layers, each of which is about 10 centimeters thick. If you plan to stay indoors in winter, an additional layer will be required.

It is not required to fix the mineral wool in a special way. It adheres perfectly to vertical slats. Slots and solid joints should be absent.

A special film is placed on the insulation, which will provide protection against moisture. The waterproofer is overlapped by 10 centimeters and fixed with a furniture stapler. For maximum protection, the joint should be sealed with tape.

Thermal insulation inside

This stage is no less important than the previous one. How to insulate the room inside, each owner decides individually. Cotton material is often preferred. This is due to its safety and environmental friendliness. However, it is very difficult to cut, which can take a long time during installation.

In some cases, you can use the same materials that were chosen for the exterior.

We must not forget that it will be necessary to make air vents so that it is possible to quickly remove condensate. They are placed on the wall above and below. If it is required to strengthen thermal insulation, it is advisable to use penofol.

Thermal insulation using penofol

In order for the material to qualitatively perform the functions assigned to it, it should be fixed in solid parts. This will help reduce the number of seams. For gluing, special tape is used. It will help ensure tightness. It is required to insulate not only the walls, but also the floor and ceiling. There are no special differences in the technology of the work. After the work is finished, you should equip the room inside.

To do this, drywall is placed on top of the heat insulator and fixed on dowels and screws. Fiberboard can also be used. The decorative finish itself can be varied, and its principles are based solely on the preferences of the owner.

Heating

In some cases, cabins must be mobile. In this situation, they often move, respectively, the use of stoves on liquid or solid fuels is impossible. It is best to give preference to electric heaters. However, if you do not intend to transport the building, you can use a wood-burning or briquette stove. The oven is surrounded by a heat shield.

To avoid accidental fire, basic safety requirements must be followed. First you need to put a metal plate on the floor. The distance to the walls should be more than half a meter. Heat shields are installed around the perimeter of the room. You will also need a chimney. The heated change house is very convenient both for living and for temporary stay in it.

An overview of the insulated change house for living with air conditioning and a vestibule is shown in the following video.

The comment was sent successfully.