What is a hammer and where is it used?

The development of the technological process contributes to the fact that many jobs are performed easier and faster. If it is necessary to drill a well, many craftsmen are wondering which tool is better to use in this case. According to experts and consumers, a hammer is the best choice for such tasks.

Features, pros and cons

A pneumatic hammer is a drilling type of pneumatic type tool that works on the basis of percussion or percussion-rotary mechanisms. Its functioning can be based on an open or underground method. This type of equipment is used when working with hard, abrasive and broken rocks. It is part of a large drilling apparatus.

This drilling tool is often used during geological exploration drilling, exploration procedures. When working with equipment, you can get a well with a diameter of 8.5-25 cm, in some cases - 80 cm. The drilling depth in this case can be from 30 to 80 meters.

The above parameters may vary depending on the quality of the rock, impact energy and rotational speed.

The drilling tool has the following advantages:

- reliability, long service life;

- the efficiency of cleaning from sludge;

- ease of use;

- the ability to quickly and easily change the tool;

- the absence of jamming of the tool during operation.

The hammer also has disadvantages, one of them is the need for a large amount of compressed air for work. Besides when using a drilling tool, foremen have to ensure the stability of the borehole walls.

Principle of operation

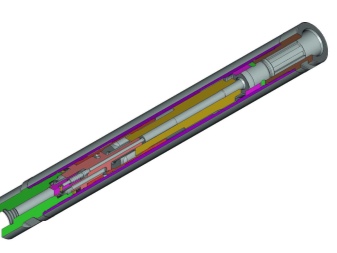

A hammer is a cylindrical type of device with a piston inside. Let's consider the principle of operation of this equipment.

- Compressed air is directed to special chambers through the swivel and drill column. Due to the difference in working pressure in the pneumatic system, reciprocating movements occur in the piston. The latter has a stem that acts on the rock cutting tool.

- Under the influence of high pressure, air is removed through the adapter due to the hole in the bit. This action entails the destruction of rocks, as well as the rise of cuttings.

- The throttle speed is influenced by an increase or decrease in air pressure, as well as the energy of single impacts.

Types

Well drilling tools can be of different diameters.

The higher the number, the higher the performance of the DTH hammer.

Currently, you can find two varieties of this tool on the market.

- Exploration, which is used for drilling wells that do not exceed 25 cm in diameter.

- Annular. This type of equipment does an excellent job of drilling hard rock. In order to protect the hammer from negative environmental factors, the tool is coated with tungsten or carbide.

According to the distribution of air, certain types of equipment for drilling wells are distinguished.

- Valve. The low pressure tool has a poppet valve that regulates the air flow.

- Valveless. The high pressure hammer is equipped with profile pistons that regulate the air pressure.This model of equipment is considered modern and improved. Valveless equipment operates on water-air mixtures or exclusively on air.

According to the option of connecting with crowns, pneumatic drilling units are divided into two types.

- With splined connection. The pile hammer ensures high quality bit centering. This increases the drilling accuracy and simplifies the collaring procedure.

- With bayonet connection. The tool with and without direct flushing is characterized by reliable docking and quick replacement.

Manufacturers

When choosing a hammer of Chinese or domestic production, it is worth considering its structural and functional features. Besides, the consumer should pay attention to the energy saving of the unit, as well as its air consumption. The model and brand of the well drilling tool is selected according to the preferences of the buyer.

The most popular models include the following:

- SANDVIK;

- Robit;

- IREV SERIES;

- Segovia;

- EVERDIGM;

- HAUS HERR;

- Wolf.

The selected hammer must fully meet the tasks assigned to it.

There are also tools for heavy working conditions, they have a large outer diameter. Deep well equipment is specially designed for high productivity processes. Such unit models are especially relevant for large volumes of groundwater and deep wells.

Care

In order to increase the service life of the hammer, as well as to prevent accidents when using it, the user should take proper care of the tool. Before installing or dismantling the equipment, turn it over and check the freedom of movement of the internal piston. In this case, the movement should be accompanied by dull sounds.

The use of the unit for drilling wells should be accompanied by its lubrication, namely the addition of finely dispersed oil to the air supply. Some technicians add some oil to the drill string during rod installation.

Most often, the hammer breaks due to clogging, piston wear.

To fix the problem, you will need to sort out the equipment, dismantling it in advance.

The comment was sent successfully.