All about Fubag motor-drills

Modern construction equipment allows you to quickly and efficiently perform a large amount of work of any complexity. Among such equipment there are motor-drills designed to create holes for posts and fences. The article will focus on models of gas drills from Fubag, one of the best manufacturers of such equipment.

Peculiarities

Motor-drills of the Fubag brand differ from similar products of other manufacturers by a number of obvious advantages.

- Reliability. The robust construction, equipped with good electronics, allows you to get the job done well. This ensures maximum operational safety of the unit.

- Simplicity. The models have only the most essential functions that make operation easier.

- Good equipment. When buying a Fubag motor-drill, the user receives several accessories and spare parts with it. This is quite enough for the normal operation of the unit for quite a long time.

- High performance. The manufacturer has made sure that the consumer can perform work of varying degrees of complexity, while maintaining control of the process itself.

- Versatility. The ability to quickly change attachments with standard connectors allows the use of augers of various diameters.

The use of these working elements can be limited only in connection with the design of a particular model.

The lineup

It is worth considering only two models of gas drills in order to understand the capabilities of the Fubag technology.

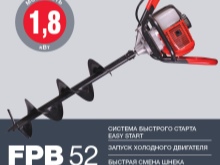

FPB 52

FPB 52 is a model without auger, but at the same time it has all the necessary characteristics for comfortable work. The main energy is generated by a 1.8 kW two-stroke engine. To supply it with fuel, a liter tank is provided, in which it is necessary to dilute a mixture of AI-92 gasoline and any engine oil in a ratio of 25: 1. The shaft diameter is standard 20 mm, the engine volume is 52 cubic meters. cm. There are 3 augers available for this model with diameters of 100,150 and 200 mm. These sizes are standard and are supported by most motor drills from various manufacturers. As for the functions, there is a quick start that allows you to accelerate the equipment to the required number of revolutions in the shortest possible time.

The strength of the structure is ensured by a high quality welded frame. Upon purchase, the user must receive a set of tools for servicing the unit, a funnel for mixing the fuel mixture, and a canister for fuel. The weight of the unit is 9.6 kg, which allows one person to fully cope with it.

FPB 71

The FPB 71 is a more expensive gas drill that offers versatility and efficiency when drilling difficult surfaces such as dense earth or clay. Compared to the previous model, the engine power has been increased to 2.4 kW. And also the changes affected the fuel tank, which now has a volume of 1.6 liters. An innovation is the support for a larger auger diameter of 250 mm. Thus, the FPB 71 is suitable for semi-professional work on a variety of surfaces.

The engine displacement of this drill is 71 cubic meters. cm. The sturdy and reliable frame design will keep the worker as safe as possible, and the quick start feature can speed up the start-up process. It should be noted that the equipment is similar to the FPB 52 model, that is, in addition to the unit itself, it consists of the same three components - tools, a funnel and a canister.It is possible to work for two operators, since the power of this motor-drill allows this in connection with its design.

In general, this model is an improved version of the previous one, because the basis has remained the same, only the technical characteristics have changed.

User manual

It is very important to operate the equipment correctly so that it serves as long as possible. That's why one should not forget to inspect the motor-drill externally before each working process, give it a minute to idle to make sure that it is in full working order. In addition, it is necessary to monitor the fuel level, and fill the tank with the correct ratio of gasoline and oil. Refueling should be done in a safe environment - no open flames around. After purchase, you must familiarize yourself with the relevant documentation, which will contain information on the use of functions and methods of working with the tool.

The gas drill should be stored in a clean place and special clothing should be worn during operation to reduce the hazard. Whenever possible, it is recommended to work outdoors so that less dust from the treated surface is inhaled by the user. As for the first start, it should be short-lived - the unit needs to get used to the loads.

The comment was sent successfully.