How to make a motor drill with your own hands?

Motobur - a special device that is used to carry out land work in a suburban area.

It is far from always possible to buy a unit, however, if necessary, a motor-drill can be assembled with your own hands. It is worth considering in more detail how to do this, and what are the advantages of this option.

Requirements for a homemade motor-drill

The modern market is represented by a large number of different motor-drills that promise the consumer high performance characteristics. Such tools are able to cope with any type of excavation.

Manufacturers release mechanical, hydraulic and other types of motor-drills, intended for digging ground pillars and other works on the site.

Key characteristics of high quality and reliable equipment.

- Power... To carry out chores with maximum efficiency, you should pay attention to this indicator. On average, the power of a motor-drill should be in the range of 3 to 5 horsepower. It is important to note that it will be easier to operate a lightweight and compact device, however, larger areas will require more powerful units.

- Engine volume. The same important criterion as power. The larger the volume of the fuel tank, the wider the capabilities of the tool. When choosing a device for this parameter, it is also worth considering the type of soil.

- Functionality... It is also called drilling capacity. It is important that the tool is able to cope with any given task.

The manufacturer's device does not always meet the stated requirements. Therefore, sometimes it becomes necessary to independently assemble a tool for working with the earth.

If it was decided to assemble a motor-drill with your own hands, it is necessary to take into account that the owner of the future device must have basic knowledge and skills in turning, and must also understand how elementary mechanisms work. No difficulties will arise if a person understands the device of a motor-drill and is able to choose the right tools and materials.

How to make from a chainsaw?

One of the most common and simple ways to create a motor-drill is assembling a tool from a chainsaw... The advantage of this option is that the result is a high performance machine in the form of improved productivity that allows you to mine even hard soils.

To assemble a motor-drill with your own hands from the Druzhba chainsaw, you will need to prepare the following materials and tools:

- chainsaw engine;

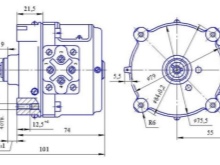

- motor-drill gearbox;

- homemade auger.

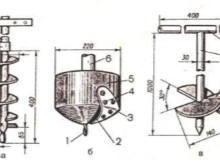

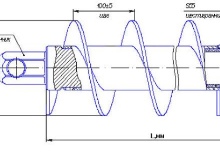

The latter can be done using a metal pipe and a classic hand-type drill. Before that, you should clarify what pipe diameter is required. The auger is long enough for comfortable work. At the same time, if it is possible to make the structure removable, then it will act as a nozzle for a chainsaw.

Before starting work, it is recommended to look blueprints and make sure the selected gearbox and saw motor are compatible. It is important that the rotation speed of the future gas drill is small in order to prevent rapid wear of the power unit. The sequence for assembling a motor-drill from a chainsaw is as follows.

- First, you will need to assemble the auger by connecting the drill nozzle and solid steel pipe.

- Next, a transmission mechanism is installed on the engine. able to reduce the speed of the tool.

- The third stage is to organize a reliable connection of the frame of the future motor-drill and auger. Additionally, it is worth installing handles on the unit, which will help make the device more comfortable to operate.

- The last step is to check how the gas drill, which was assembled by hand, works. To make the operation of the motor-drill convenient and safe, it is recommended to place the start button closer to the handles.

Making from a drill

Another option for assembling a motor-drill with your own hands involves the use of a punch or drill. This option is inferior in power, but it still copes with the tasks. To create a motor-drill from a drill, you yourself will need:

- reducer;

- drill;

- homemade auger;

- fasteners.

When choosing a drill, it is better to give preference to models with a power of 2 kW.

The procedure for assembling a motor-drill is carried out in almost the same way as described in the previous version. The owner of the unit will need to connect the necessary elements in the desired sequence using fasteners.

To create a functional device, experts advise using a reversible hammer drill.

Such a unit will last a long time and will cope with a task of any complexity, regardless of the fact that the power of the device is less than required.

You can learn more by watching the video.

We make from a trimmer

The third most popular option for self-assembly of a motor-drill is using a trimmer. Such petrol cutters for lawns are widespread almost everywhere, so it will not be difficult to find the necessary tools and materials for installing a soil drilling device.

It is worth noting that the technical parameters of the chainsaw are higher compared to the trimmer, so the resulting device is useful for working only with soft ground.

It will also be necessary to install a transmission mechanism in the structure in order to reduce the rotation speed of the unit and extend the life of the device.

Alteration of brushcutters for a motor-drill implies the following scheme.

- It is necessary to assemble the auger using the drawings. You will need a drill and pipe for assembly.

- The second stage is the installation of the transmission mechanism on the engine.

- The third step is to connect the elements with fasteners.

It is recommended to assemble the auger from solid steel to prevent its breakage if the device encounters stones or other solid objects in the process.... If this is not taken care of, the device will quickly become unusable.

Also, for more convenient operation, it is worth considering the possibility of dismantling the drill from the motor in order to make a trimmer attachment in this way.

Recommendations

If we make a comparison between a self-assembled device and a purchased unit, then the first option is considered more budgetary. To carry out land work on a personal plot, a self-made unit will be quite enough, provided that there are no too hard soil rocks.

In the process of self-assembly of a motor-drill, it is recommended follow safety precautions and use only reliable and durable tools and materials... Also, experts advise you to familiarize yourself with the device of a motor-drill, the design of simple mechanisms and the principle of operation of the future tool.

The comment was sent successfully.