Features and selection of pole drills

For the construction of fence structures or for the construction of the foundation, you cannot do without the installation of pillars. To install them, you will need to dig holes. It is difficult to dig holes by hand using the tools at hand, especially in dense soil. To facilitate earthwork, pit augers were created.

Description and purpose

Post drill - equipment for creating holes in the soil with the required diameters and depths. Basically, such a device is used in the construction industry. Cylindrical holes are required for the installation of posts and various support structures. The units are also used for drilling under pile foundations.

There are also garden hole drills - they are actively used in everyday life for the improvement of a vegetable garden or a personal plot. The tool will be required:

- to drill the ground for a chain-link fence;

- erect supports for the summer gazebo;

- planting young seedlings - in this case, it will take much less time and effort compared to making holes with a bayonet shovel;

- drill small compost pits;

- to feed the plants - for this, small holes are created around them with the help of a yamobur, intended for laying peat or humus.

The equipment, depending on the type and working part, is used both for soil and for working with rocks of different density and structure.

Some devices are designed for soft soils, others for drilling stony and frozen ground. Thanks to the large selection of units, you can easily select a drill for specific working conditions.

Varieties

Earth drills are divided into several types depending on the purpose, size and power indicators. On sale there are powerful attachments for installation on tractors, walk-behind tractors or other equipment. There are also small drill bits for a drill or hammer drill.

Manual

These include non-motorized tools. Hand tools drill the soil by applying the physical force of the operator. They have the simplest design, which includes a sharp metal rod with a screw knife and T-shaped handles. Most often they are made of steel, there are forged variations. The handles of most models are steel, some models have rubberized inserts on the handles. The weight of most devices ranges from 2 to 5 kg, and their length does not exceed 1.5 m.

On sale meet collapsible solutions, providing the possibility of removing the screw. By changing the nozzles, using one device, you can make several holes with different diameters and depths. Manual variations are suitable for creating small indentations up to 200 mm.

The advantages of such a tool include:

- reliability and durability of the structure;

- affordable cost - of all the presented types of drills for pillars, manual ones will be the cheapest;

- easy transportation;

- convenience when moving and storing equipment due to its compactness and low weight;

- the ability to organize a workflow in a limited space.

The main disadvantage is the low efficiency of the tool. - it directly depends on the physical training of the operator... Judging by the reviews, when drilling a person's strength is quickly depleted, it takes a long time to recover.

It is difficult to work with a manual device, especially when stones or rhizomes of massive trees fall under the tip - in this case, the equipment will stop burying. To continue working, you will need to remove the interfering object to release the trajectory of the knife.

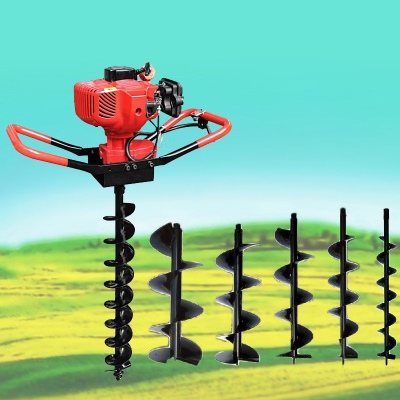

Gasoline

A gas drill (motor-drill) is a small-sized mechanical tool for performing small land works. The unit has a simple design. Its main mechanisms are auger and a motor. When the engine is started and the lever is held, the auger begins to move clockwise, its cutters cut into the ground, creating a hole with the desired parameters. Each motor drill has a starter, a motion blocker and an emergency button to force the engine to stop.

Manufacturers offer several types of models of auger gas drills. There are solutions equipped with devices for the automated ejection of loosened soil from the created recess. To activate this function, you need to press the lever located on the handle.

Gasoline drilling equipment, depending on the modification, has different technical characteristics. It differs in power, screw diameter and motor volume.

Inexpensive models are equipped with engines of 3 liters. with. Is the minimum power of the unit. The higher this indicator, the faster the technique will work.

The advantages of gasoline designs:

- high efficiency compared to hand and electric drill:

- minimum power costs for the operator;

- installation mobility;

- the possibility of changing the augers, due to which it is possible to vary the parameters of the diameter and depth of the hole.

The disadvantages include high cost of rigs, noise during drilling and environmental damage due to emission of exhaust gases.

Hydraulic

Such equipment is two-block manual installation, including a hydraulic station and an electric motor with a control unit. These 2 mechanisms are separate or connected with a bar. The hydraulic units are equipped with lightweight gerotor motors and gear pumps. They differ high reliability and durability... Despite the lightness and compactness of these mechanisms, they have significant technical characteristics that allow drilling in soils of the 4th category (they include heavy clay, frozen soil).

The advantages of hydrodrills include:

- safe operation - in case of overloads, the valve releases excess oil pressure, protecting the operator from kickbacks, and the hydraulic system from premature wear;

- reverse function - makes work more convenient due to the possibility of freeing the stuck auger due to reverse rotation;

- possibility of drilling at an angle (provided in installations for 2 operators);

- easy maintenance, which consists in the timely replacement of filters, as well as oil in the engine and hydraulic system.

The disadvantages of hydraulic machines include their large dimensions, noise during work and high cost. Such equipment is not environmentally friendly due to the exhaust gases emitted during the drilling process.

Electrical

Such tools are the least in demand among other types of drills. They are similar in design to gasoline ones. The only difference is the type of engine. Three-phase electric models operate on a 380 V network, two-phase ones are connected to a 220 V household outlet.

The advantages of such models:

- environmental friendliness - unlike gasoline and hydraulic installations, electric ones do not emit harmful substances into the atmosphere;

- quiet work;

- light weight compared to gasoline and hydraulic equipment.

The main disadvantage of electric drills is their attachment to the outlet, as well as the limited radius of use by the length of the cable cord. It is not possible to use such equipment in non-electrified areas.Another disadvantage of the tool with an electric drive is the limited assortment.

Nuances of choice

An earth drill is selected depending on the type of work and their scale. For example, for occasional gardening jobs, an inexpensive hand tool might be the best choice. It is ideal for digging small holes for planting seedlings. If there is a need to perform one-time large-scale work, it is advisable not to spend on the purchase of expensive equipment, but to rent it.

If long excavation work is ahead, it is better to buy a gasoline or hydraulic tool. When choosing, you need to pay attention to several important parameters.

- Engine... The devices are equipped with 2 and 4-stroke motors. The latter are distinguished by a more economical consumption of fuel resources. They are quieter, but they have more power. 2-stroke engines are cheaper. It is preferable to choose them for solving small everyday tasks.

- Motor power. The higher the readings, the faster the equipment will drill the hole.

- Engine volume... It must be selected taking into account the diameter of the screw. For example, for D 150 mm motors with a volume of 45 cm³ are suitable, for D 200 mm - 55, for D 250 - 65 cm³.

- Weight... Hand and power drills should be held in hands during operation. Equipment that is too heavy is inconvenient to operate, since it will require a lot of power inputs from the operator. It is also best to refuse to purchase an overly light instrument. To reduce weight, its working parts are made of thin-walled steel, which, due to its softness, quickly deforms under loads.

- Screw... When choosing, you need to take into account the dimensions of the bore diameter. It can be 20 or 30 mm. The diameter of the screw itself ranges from 50 to 300 mm. The most popular are D 100, 150 and 200 mm. In addition, there are augers with an expander on sale - they are considered more convenient to use.

- Hand grips... They should be ergonomic, soft and even. Handles with embossed rubberized inserts are uncomfortable as they press on the skin while operating the equipment, causing pain to the operator.

- Fuel tank... It must be capacious (models with a tank volume of at least 2 liters are preferred), equipped with a convenient wide neck for filling fuel.

If the equipment is taken for regular excavation work, it is advisable to give preference models with additional options. Useful functions include reverse rotation of the auger, fast braking system (prevents damage to the gearbox when the shaft is jammed).

Earth drills with a damper spring are considered more convenient in work. It is designed to dampen vibrations.

Operating tips

Ground hole must be used strictly on purpose, taking into account the model of the tool and the characteristics of the soil. It is important to study the specifications before digging holes. For the use of manual hole drills, the additional purchase of tripods is recommended - such a system ensures the vertical position of the tool and facilitates work when it is necessary to extract the equipment from the ground.

When working with mechanical drills, you should adhere to safety precautions:

- grab the handles of the unit with both palms, if the device is designed for two operators, then 2 people must work (models with a mass of less than 10 kg are designed for 1 operator);

- do not put your feet under the cutters working apparatus;

- it is not allowed to leave the switched on equipment unattended;

- mixing fuel and oil for 2-stroke engines must be done in strict accordance with the instructions - with the wrong choice of fuel or if the proportions are not observed, the risks of premature breakdown of the unit increase significantly;

- before using the equipment, it is recommended prepare the working area by clearing it of stones and rhizomes - foreign objects often damage the cutters.

Before storing the unit for storage, it must be cleaned of dirt and dried. With a gasoline powered tool, drain the fuel completely. The equipment is stored strictly upright.

The comment was sent successfully.