All about imitation of timber

Imitation of a bar is a popular finishing material used for exterior and interior decoration of buildings. Specially processed boards from larch and pine, other types of wood can have a natural shade, as well as be painted or glued, with other finishes. It is worth understanding in more detail how the imitation of timber differs from the lining, what grades and classes it is.

What it is?

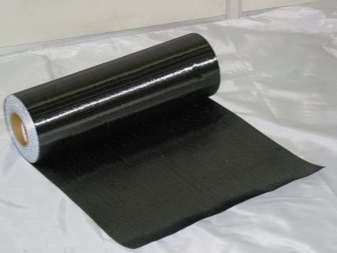

A false beam is a board made of natural wood or a panel made of artificial material, the reverse side of which imitates the surface of a full-size analogue. Outwardly, it does not have many differences from the Euro lining, but in fact, the difference is significant. False beams have increased width and thickness in comparison with thin finishing boards. The wall faced with it looks as if it was assembled from massive elements. In this case, not only a frame structure can be under the coating, but also a main wall made of brick, concrete or artificial stone.

The material is called imitation of a bar for a reason. Its front side is smooth, and the back is profiled, it has horizontal grooves. In fact, the material looks the same as a bar, but has a smaller thickness, and there are also spikes and grooves here, allowing for easy installation. Such a fastening helps to avoid the formation of gaps, which look not very aesthetically pleasing.

The decorative finish of the material is quite diverse - you can find heat-treated, tinted materials, or you can apply impregnation yourself.

How is imitation of a bar made?

The production of imitation timber is carried out by machining coniferous wood - inexpensive, versatile, with an attractive surface pattern. Most often, spruce, pine acts as a base, premium options are made from larch or cedar. Hardwoods are used less frequently. After sawing the imitation of the timber to the desired size, further processing is carried out, including a number of stages.

- Drying. It takes place in special chambers allowing to lower the natural moisture content of the material to 12-18%. In addition, during the drying process, the resin contained in the conifers hardens, increasing the strength of the finished false beam.

- Sawing to size. It allows you to get finishing materials of the desired format.

- Processing with special compounds. This stage is necessary to combat insect pests, to prevent the development of mold and mildew on the surface of the wood. And also protective compounds can significantly increase the resistance of wood to external influences of an atmospheric nature, temperature extremes.

- Sampling of edges. On the mounting edges of the boards, groove-groove recesses are selected. The work is carried out using modern milling machines.

- Surface grinding. It is needed in order to ensure sufficient smoothness of all surfaces. It is much more comfortable to mount such lumber, you can not be afraid of splinters.

Upon completion of all production processes, the bulwark is sent for sorting. Rejection is carried out taking into account the established standards for the presence or absence of defects.

What is the difference from lining?

The main difference between timber imitation and lining is in their parameters.Both of these types of planed lumber are used for decorative finishes. But the lining is best used indoors, since it is less adapted to temperature extremes.

Imitation timber provides opportunities for choosing the place where it will be applied - in the interior or exterior of the building.

There are other differences as well.

- Thickness. The lining is not available in standard sizes exceeding 16 mm. It is too thin for the outer skin. In the case of a false beam, the thickness varies in the range of 16-37 mm.

- Panel width. Since the imitation should give the impression that the building was erected from natural timber, its dimensions are as close as possible to this material. Lined with clapboard exterior walls are more likely to evoke associations with a fence or a barn.

- Installation method. With a false beam, only fastening in a horizontal plane is possible. The lining is placed vertically, longitudinally, diagonally. There are no restrictions.

These are the main differences between the materials. In addition, imitation of a bar is more resistant to external factors, since it passes through chamber drying.

Varieties

Depending on what kind of wood is used in the manufacture of false beams, the finish may have a different appearance. From round wood, boards for its base are dissolved to the desired size. Further processing of the wooden surface depends on the characteristics of the texture. In some cases, the material is additionally aged or fired to obtain unusual visual effects. For example, it is quite possible to create an imitation of oak or wenge from wood of inexpensive varieties.

It is worth talking in more detail about how the false beam looks, depending on the type or finish. There are several types of material.

- From larch. Usually wood of the Karelian or Angara species is used, which has a uniform color of a pleasant creamy salmon shade. It is worth considering that larch wood is very hard and dense, it practically does not absorb moisture, but it protects well against heat loss. The material will provide good thermal insulation for the facade.

- From pine. A very light version with a pronounced texture. Natural pine has a shade of sand, sometimes with a slight yellow, amber tint. Such imitation of a bar is well suited for interior decoration, but it is quite capable of ennobling the facade of a frame house from budget materials.

- From cedar. Cedar wood is rarely used as a facade finish. Natural cedar has a noble dark shade and a pleasant specific aroma.

Such a false beam is well suited for facing verandas and terraces, and is able to decorate an office or living room.

- Oak. Another option that allows you to get a respectable interior decoration, even if the house is built of stone. Wood of this type is rather dark and without tint, looks good in the cladding of ceilings, floors, wall cladding of the office or dining room. In external cladding, such an imitation of a bar is used very rarely.

- From alder. Soft and reddish, this hardwood is renowned for its toughness. Imitation of a bar from it is rarely made, mainly by individual order.

- Linden. The soft, almost white heart of this creamy wood looks very attractive and is highly regarded for the interior decoration of residential buildings. Imitation of a bar can also be used in the design of a home sauna or bedroom, it has a pleasant shade and a special aroma.

- Aspen. Inexpensive false beam made of this material has a shade of yellowish or off-white. It is strong, durable, lends itself well to decorative finishing. Suitable for facade cladding.

- Heat treated. This imitation of a bar has a special appearance.It is processed with high-temperature steam, after which the material acquires darker, more saturated shades, as if baked. Thermal wood is very popular in facade decoration, but it will definitely find a place in the interior.

- Brushed. This imitation of lumber gives the building's interior and facade a special appeal. The artificially aged board looks very respectable, the natural ornament is more clearly drawn in it. The facade finish processed in this way is more expensive than usual.

- Painted. Artificially tinted wood is distinguished by a variety of colors and shades. Inexpensive spruce or pine can be tinted to match more noble wood species, giving them respectability. In addition, the coating can be continuous - bright, hiding the natural texture of the material.

Unlike laminated veneer lumber, in which you can see traces of the connection, the imitation has a solid, seamless texture that looks very attractive both when made from pine needles and when using hardwood.

Varieties

The timber imitation class largely influences the cost of this type of lumber. The product range includes 3 main categories, each of which must meet certain standards.

"Extra"

High quality material, practically free from defects. The imitation of a bar of the "Extra" grade is suitable for finishing the interior and the front of buildings; Among the permissible defects in the standard, the presence of small cracks in the end part, resin pockets with a diameter of up to 2 mm each is indicated.

"A / AB"

The middle class of a false beam is characterized by the presence of permissible defects, including knots, on an area of no more than 10% of the surface. This material is most often used in the exterior cladding of buildings.

"BC"

Imitation of a bar of this class is made from inexpensive raw materials, abundantly covered with knots, resin pockets. The presence of traces of rot in the form of black spots and stripes is acceptable. The volume of permissible defects can reach 70% of the entire area of the board. This greatly influences her choice. But if the affected areas are not too densely located, such a false beam is suitable for the outer cladding of the house or for finishing the functional areas inside it.

Sizes overview

A fairly wide imitation of timber looks attractive in the interior, in the facing of the facades of the building. It is produced taking into account the requirements of GOST 24454-80 standards. According to this document, the standard dimensions of the bulwark must correspond to the standard values.

- Length 3 or 6 m. Shorter panels are produced by sawing standard panels.

- Width 110-190 mm. In this, it is fully consistent with similar indicators of a building bar.

- Thickness. It can be 16, 18, 20, 22, 28 or 34 mm.

- The mass of panels is standardized for products that have passed chamber drying. For coniferous wood, the weight of 1 m2 should be 11 kg.

Regardless of the type of wood, each element of the false beam must comply with the established standards.

Color solutions

Colors traditional for imitation of timber are not obligatory at all. If you do not want to preserve the natural shade of wood, especially in the decoration of the facade, you can tint the surface of the material in one of the popular shades:

- pistachio;

- brown - from ocher to rich smoked oak;

- light beige;

- Gray;

- peach;

- Orange.

Tinting allows you to preserve the natural structure of the tree, provides its clearer manifestation. At the same time, you can always choose a complete painting, if you want to make the facade brighter or better protect it from atmospheric influences.

Interior use

The use of imitation of a bar in the interior of a house or apartment allows you to give the space a special warmth, to correctly place accents.With the help of such panels, it is easy to hide the unevenness of the walls, since the installation is carried out along the guides. It can be used both in the bathroom and in combination with drywall or other types of surfaces.

When decorating rooms, you should adhere to the rules of color harmony. The hallway or veranda is finished in light colors. Bedroom, living room, study or library - in the dark. The choice of wood species is also important. Oak, larch, linden, alder look good in the interior.

The panels can be mounted in a monolithic or combined way. The first provides for the continuous use of false beams from ceiling to floor. Combined solutions allow the use of stone, glass, and other materials. You can sheathe only one accent wall with wide wood panels, creating a natural panel.

Nuances of choice

When choosing a suitable imitation of timber for finishing, it is important to pay attention to the thickness of the boards to be mounted, as well as their width. These indicators largely determine the final appearance of the finished coating. Indoors, in interior decoration, a thin imitation of a bar is most often used - no more than 20 mm, with a surface of a minimum width. For the facade, especially if the role of the hanging material is not only decorative, it is better to give preference to massive and wide options for finishing boards without knots and obvious defects.

Besides, when choosing an imitation of a bar, you need to make sure that the moisture content of the products does not exceed the established 18%. All boards should not have visible roughness, rough areas or through cracks.

The grooves and pins must fit snugly against each other, excluding the formation of gaps.

Mounting

Correct installation of an imitation of a bar involves the use of cleats - special fasteners hidden under the front of the panel. If the exterior wall of a building is made of natural wood, you will have to wait for the structure to shrink. It is not customary to mount a false beam vertically on the facade, but on a balcony or indoors with low ceilings, the material can be positioned perpendicular to the floor. When cladding a veranda or in outdoor decoration, it is better to follow the traditional laying in a horizontal position.

The procedure includes several steps.

- Surface preparation. It is cleaned of dirt and dust, traces of mortars.

- Installation of waterproofing. For wooden structures, it will be film, for brick and concrete - coating, on a bitumen basis.

- The formation of the lathing. It is made from wooden blocks with a cross section of 50 mm for the facade or from an aluminum profile inside the house. In the presence of height differences, they are compensated by silicone pads.

- Fastening the guide bars in the corners. Their position is set according to the level. The step between the others should be 50-80 cm.

- Installation of thermal insulation. A protective film is laid on top of it.

- Installation of a false beam. If it is attached to cleats, they are nailed to the base of the sheathing with galvanized nails. The starting board is set up with a comb upward using a horizontal level, and is attached to the clip by the grooves. The next one is directed downward with a spike, knocked out with a hammer, with a gap of about 5 mm. Work is done from bottom to top until the entire wall is covered.

Installation can be carried out without clamps, using galvanized nails or self-tapping screws fixed in the ridge. These methods are suitable if you need to install the cladding vertically.

Advice

Despite the fact that the imitation of the timber is dried during production, for operation in high humidity conditions outdoors or indoors, the surface must be additionally treated with an antiseptic. In some cases, wax polishing is used, which performs decorative and protective functions.

When choosing a material for cladding the walls of a bath or sauna, false beams can also be used. You just need to think carefully about the choice of material. Conifers will not work. They will release resin when heated.

Here you will have to spend money on imitation of hardwood.

Cedar cladding is not suitable for children's rooms. From the strong specific scent of the tree, the baby may be sick or dizzy.

When installing a false beam indoors, it is recommended to pre-keep the boards at room temperature for several days. This will prevent distortion of their geometry after fixing on the wall.

The comment was sent successfully.