Varieties of beam supports and their application

When constructing buildings made of wood, it is difficult to do without auxiliary fastening elements. One of these fasteners is the support for the timber. The connector allows you to fix the bars to each other or to another surface. The article will discuss the features of fasteners, their types, sizes and tips for use.

Peculiarities

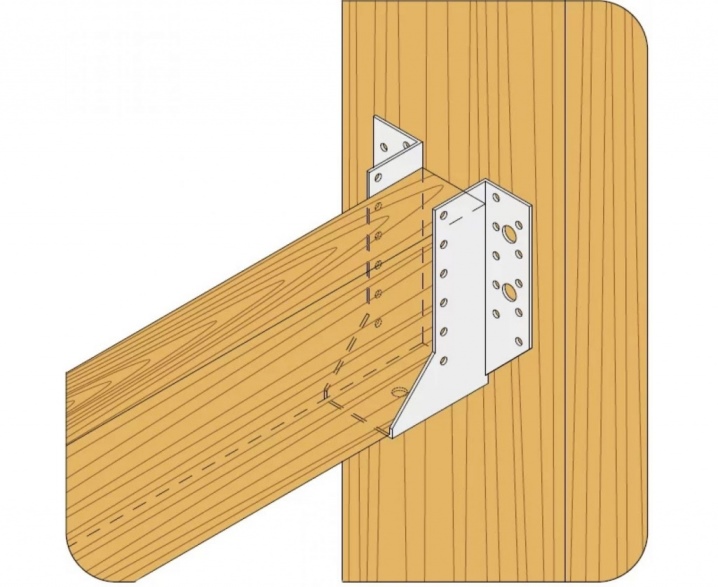

The timber support is a galvanized metal perforated connector. The fastener has a combined structure, consists of two corners and a crossbar in the form of a plate, which serves as a support for the timber.

This fastener is also called a beam bracket. The product is made of dense metal and coated with a layer of light zinc. The zinc coating significantly increases the service life of the product, protecting the mount from external influences.

Each side of the support has drilled holes for bolts, dowels or nails. Several shelves at the base of the bracket also have multiple holes. Due to them, the element is fastened to a transverse beam or concrete surface. Fixation is done with anchors.

Here are the main features of the timber support.

- The use of a support for the timber significantly reduces the construction time. Sometimes construction takes several days or even weeks.

- There is no need to use heavy equipment. It is enough to have a screwdriver.

- Fast installation.

- There is no need to make cuts and holes in wooden structures. Thus, the strength of the wood structure is maintained.

- Possibility of choosing products for fasteners: bolts, screws, dowels.

- The special coating of the mount prevents rusting.

- Long service life.

- The strength of the connections.

Species overview

Supports have a number of modifications with their own characteristics, structure and purpose. It is worth taking a closer look at the types of brackets.

Open

Open fasteners look like a platform with strips that are bent outward. The design has crimp sides with holes of different diameters. There are several modifications of open supports: L-, Z-, U- and U-shaped.

An open support is the most demanded fastener for joining wooden beams in one plane. The fasteners are easy to use, significantly reduce the operating time, increase the rigidity in the corners of the joints. For fixing, dowels, screws, bolts are used. The connecting product is selected strictly according to the perforation diameter of the metal support. Open brackets are made from a dense galvanized sheet of metal with a thickness of 2 mm.

During production, special technologies are used that increase the service life and allow the use of products for finishing work outside.

Closed

These fasteners differ from the previous type by the crimp sides bent inward. The support is used to fasten a wooden beam to concrete or a brick surface. Self-tapping screws, nails, dowels or bolts act as a retainer. Closed fastening is produced by cold stamping. The structure is made of carbon material with a galvanized coating, which indicates the durability of the product. Thanks to the coating, the closed brackets are not exposed to rust and sunlight.

The products are able to withstand heavy loads and adverse weather conditions.

When installing a closed support, the beams are rigidly compressed, which gives a tight and reliable fixation of the connection unit. This type of support is used when connecting load-bearing beams. For fixing, anchors or self-tapping screws are suitable, corresponding to the diameter of the perforation.

Sliding

A sliding bracket is used to reduce the deformation of the timber frame. The fasteners provide the mobility of the rafters by fastening their ends like hinges. A sliding support is a metal element from a corner with an eyelet and a strip, which is placed on the rafter leg. The mounting bracket is made of 2 mm thick galvanized steel sheet. The use of a sliding support assumes installation parallel to the offset. The fastening provides reliable fixation of the connecting nodes, is easy to install and efficiently eliminates deformation.

Driving and mortgages

Driven supports are used in the construction of small fences and lightweight foundations. The support for the timber into the ground is a two-piece construction. The first element is designed to fix the timber, the second looks like a pin with a sharp point for driving into the ground. Vertical fasteners are easy to use. The bar is inserted and fixed with self-tapping screws. The finished structure is hammered into the ground and can serve as a reliable support for the post.

The embedded bracket has its own characteristics. It is used to fix the support to the concrete. The wood and concrete surface do not touch in any way, which increases the strength and durability of the structure.

Adjustable foot or expansion bracket

The adjusting support serves to compensate for the shrinkage of the timber. Wooden beams and logs settle down when they dry. The percentage of shrinkage is up to 5%, that is, up to 15 cm per 3 m of height. Compensators equalize the shrinkage of the frame.

The compensator is also called a screw jack. The appearance, indeed, resembles a jack. The structure consists of several plates - support and counter. The plates have holes for fastening. The plates themselves are fastened with a screw or metal screw, which provides a secure and stable position. Expansion joints withstand heavy loads and have a corrosion-resistant coating.

End-to-end connector

This connection is called a nail plate. The element looks like a plate with studs. The thickness of the plate itself is 1.5 mm, the height of the spikes is 8 mm. Nails are formed by using the cold stamping method. There are up to 100 thorns per 1 square decimeter. The fastener is a connector for the side rails and is installed with the spikes down. The plate is completely hammered into the wooden surface.

Dimensions (edit)

When constructing wooden structures, bars of various widths and lengths are needed. Supports of a certain size are selected for them:

- dimensions of open brackets: 40x100, 50x50, 50x140, 50x100, 50x150, 50x200, 100x100, 100x140, 100x150, 100x200, 140x100, 150x100, 150x150, 180x80, 200x100 and 200x200 mm;

- closed supports: 100x75, 140x100, 150x75, 150x150, 160x100 mm;

- sliding fasteners are of the following sizes: 90x40x90, 120x40x90, 160x40x90, 200x40x90 mm;

- some dimensions of driven supports: 71x750x150, 46x550x100, 91x750x150, 101x900x150, 121x900x150 mm.

Application Tips

The most common mount is considered to be an open support. It is used in the assembly of wooden walls, partitions and ceilings. There are 16 standard sizes of open brackets to accommodate different cross-sections of timber. For example, a support 100x200 mm is suitable for rectangular beams. The fasteners are connected to the bar using self-tapping screws. No special mounts or equipment is needed.

An open joint is used to create a T-piece. The beam is fixed with its end to the crown material on both sides of the joint line.

A closed fastener creates an L-shaped or corner connection. The installation of the element is slightly different from the installation of the open-type bracket. The use of closed fasteners implies installation on the crown itself. Only then the docking beam is laid. For fixing, use ordinary self-tapping screws.

Installation of the sliding bracket involves installation parallel to the rafter leg. The angle is set perpendicularly in order to compensate for the shrinkage process as much as possible. Sliding fasteners are used not only in the construction of new buildings. It can also be used for dilapidated premises. The use of a sliding support significantly increases the strength of timber structures.

Before installing push-in fasteners, you should first assess the quality of the soil. It is worth knowing that in sandy and watery soil, supports for vertical piles or pipes will be useless. They won't hold on. They also cannot be driven into the stony ground. These factors need to be considered.

Driving in supports begins with the preparation of the timber. The size of the bar is selected based on the size of the saddle into which the post or pile will be inserted. The location of the bracket is calculated according to the dimensions, and a recess is dug out. The bracket is installed in the recess with the tip down and hammered in with a hammer. In the process, you need to check the level of the pile to maintain a strictly vertical position.

The embedded connector is often used in concreting or subsequently to install a support bar. Previously, holes are drilled in the concrete surface, which is 2 mm less than the diameter of the pin of the embedded element. The bracket is connected to the concrete surface with dowels or anchors.

The nail support or plate is easy to use. It is installed with the nail part down and hammered with a sledgehammer or hammer. The element is suitable for connecting side rails in a single plane.

Before installing the adjusting expansion joints, it is necessary to make markings for each of them. This takes into account the length and width of the wooden beams. After that, the expansion joints are fixed, and the height is set. If necessary, the level is used to correct the corners.

Fasteners are selected based on the diameter of the perforation of the supports and the type of connection. The connection of fasteners and timber is performed using self-tapping screws, bolts, nails or anchors. For example, when installing conventional open or closed supports, self-tapping screws are used. For anchoring heavy timber structures to concrete or brick, it is best to choose anchors or dowels. Products are able to withstand high loads and pressure.

Supports for timber have a number of varieties, which allows you to choose a bracket for a specific type of connection. All types have their own characteristics, sizes and characteristics. However, they have one thing in common: long service life and ease of use. This article will help you understand and choose a support for a specific purpose, and tips for use will eliminate the appearance of errors during installation.

The comment was sent successfully.