All about sidewalk curbs

Landscaped urban areas, modern parks, private suburban homesteads always delight us with their finished look. This effect is achieved largely due to the details of the finish, for example, sidewalk curbs.

Description and functions

Sidewalk curb is an important element of space decoration. Its variations and uses are varied. But before paying attention to the nuances of the use and production of this type of frame, it will not be superfluous to decide on the terminology.

"Curb" or "curb"? Both names are correct to identify the side stone. The difference is how you stack it. Actually, the two concepts are considered synonymous. Of course, the word "curb" has a general meaning.

The sidewalk block, in addition to the aesthetic side, has a number of practical functions. For example, curbs direct the flow of water towards stormwater runoffs while maintaining the integrity of the roadway. The curb is an indispensable element for paving slabs, it perfectly protects it from destruction, preventing erosion of the paved surface. Let's dwell on the features of the sidewalk curb.

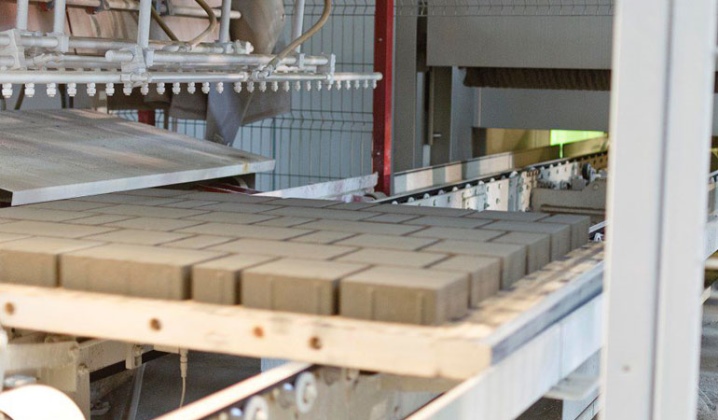

How are they produced?

Side stones from a cement mixture are made in two ways. The first option is fully automated. As a rule, the result of such production has many advantages, therefore it is more often used. Due to the even distribution and additional compaction of the mixture during production, the curb block is proportional, smoother and more robust. Since a small amount of water is used in the manufacture, the number of pores in the structure of the product is minimized. These curb blocks are reliable and aesthetically pleasing, they are durable and frost-resistant.

The second option involves the manufacture of sidewalk curbs by hand. Manual labor also involves the use of ready-made forms to fill them with a mixture, followed by vibration compaction. However, the quality of the products is often not so good, and the resulting blocks do not differ in durability. In such blocks, a large number of large pores often remain, affecting the strength. The percentage of defective blocks is also high. Distorted geometry reduces the aesthetic properties of the border.

In a word, the result is not of such high quality, but it is much cheaper to manufacture.

Overview of varieties

The side stones are very diverse both in types and in the method of application. The following groups are distinguished according to their purpose.

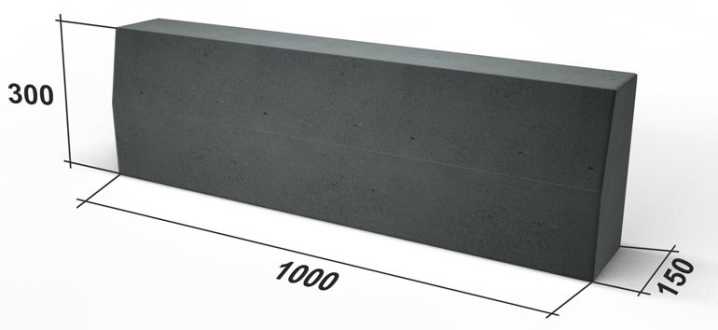

- Road - a concrete stone of great strength and impressive weight (95-100 kg), used for bordering highways. As a rule, the road curb has a typical size of 1000x300x150 mm.

- Sidewalk - to create frames for sidewalk paths, playgrounds, private buildings, flower beds and similar green areas. Sidewalk curb exists in a variety of forms, composition, sizes, color shades.

This type of curb block is more convenient for independent use in terms of its dimensions (thinner, lighter).

- Decorative - serves to frame decorative components of landscape design. In the case of a decorative curb, functional characteristics recede into the background. The priority is form and color.

Depending on the production technology, there are vibropressed or vibrocast (vibrocast) sidewalk boards. The production of vibropressed curb blocks is exclusively automated. It is carried out using special equipment. Stamping of semi-dry bases gives the products an aesthetically proportional shape.

Products made from semi-dry hard concrete mixes contain a small percentage of water, the excess of which evaporates due to interaction with cement. As a result, the minimum amount of moisture contributes to the formation of a minimum number of pores in the finished border, its resistance to temperature extremes.

This method of production allows room for the stamping of two-layer road curbs with a layer of outer cladding.

The facing layer is wear-resistant and has a low water absorption coefficient. Its fine-grained crushed stone surface is notable for its evenness. Automated pressing results in product strength and good abrasion resistance. The products themselves are also lighter, which means they are convenient for transportation and installation.

The vibratory casting unit is produced using manual labor. This production is less costly and involves a minimum of tooling (mainly, we are talking about the choice of molds for manufacturing from the whole variety). The disadvantages of vibrocasting curbs are significant. The manufacturing technology also uses vibration, but without compaction. In the case of vibrocasting blocks, a large amount of water during manufacture leads to a significant number of pores.

Vibrating curbs often sin with curved geometry of shapes. They are heavier and absorb a lot of moisture. This affects the service life and wear resistance. At the first severe frosts, there is a risk of curb destruction.

By material of manufacture

Currently, in construction, the basis for the production of side stone due to the relative cheapness is mainly heavy concrete. Crushed stone and sand are used as accompanying components. The paving vibropressed and vibrocast curb is made of cement. In the case of a vibrocasting block, it is not out of place to take into account the fact of using a reinforced iron frame in production.

The reinforced frame has a tendency to shift towards the edge when filling forms. As a result of the short-term operation of such a product under the influence of wear, the reinforcement is not only detected visually under chipped curbs, which does not in the best way affect the aesthetic perception of the curb, but the destruction of the entire product is also accelerated due to rapid metal corrosion.

Sometimes, in the manufacture of borders, special additives are used, which accelerate the drying process and help to give the blocks additional strength.

In addition to sidewalk curbs made of cement, granite side stone is more and more confidently occupying its niche. Its production is more expensive than its concrete counterpart, but it has its economic justification due to a number of indicators. Such a block is much more durable and frost-resistant. Its wear period is long. A granite curb usually does not require replacement even after 10-15 years of operation.

The aesthetic benefits of granite curbs are obvious. This border brings monumentality to the implementation of the landscape project. Granite curbs are also very diverse in form and surface.

Separately, mention should be made of the plastic border, which has variations in both texture and shades. They are moisture resistant, easy to install, and quite cheap. Their main disadvantage is fragility in the event of any mechanical stress.

By color

Variety of colors is another way to differentiate your border. At the moment it is in great demand. For example, many want to transform the courtyard of their country house or garden paths in a spectacular way, making certain requirements for the color of the tile and border. In the case of vibrated curb blocks, the cost of painting is high. That is why their color is predominantly gray.

Applying paint to such blocks will also have a short-lived effect.

Vibro-compressed cement blocks are currently available in a wide variety of colors. In terms of color, in addition to gray, brown, red, dark blue options, etc. are most often common. Granite blocks also differ in both the variety of textures and a large number of color shades.

Dimensions and weight

Currently on the market there are many options for sidewalk curb with different dimensions. Height, width and length can vary, making it easy to find the right option for specific purposes. The standard length of the block is either 50 centimeters or 1 meter.

Unlike a road curb, for example, the large thickness of the sidewalk block is not so fundamental in cases of landscaping the territory of private houses. It is quite possible that the curb block should be narrow and high in overall dimensions in order to protect the space from dirt from adjacent zones.

The average weight indicators of the sidewalk curb fluctuate within 15 kg. But depending on the production technology, structure density and material, the weight of the same volume can vary greatly. In this connection, to calculate the mass of a certain number of blocks expected to be purchased and transported, it will be useful to check with the manufacturer how much the product weighs (1 piece).

Marking

The marking of curb blocks has its own state standardization. An example of marking in accordance with GOST - BR100.20.18. The letters in it denote the type of border (BR - straight ordinary; BU - straight with widening; BL - straight with a tray; BV - entrance; BC - curvilinear). Further, the length, height and width (100X20X18 cm) are indicated. The fourth number may also be present and indicate the radius of curvature (in the case of curved borders). In addition, the curb block has a certain strength grade, determined by a number with a capital letter "M" (M400, M600).

Criterias of choice

The choice of curb is determined by the tasks and budget in each case. If we are talking about the arrangement of the personal area of elite real estate, it is better to consider the use of granite and vibropressed curbs. In the case of budget solutions, for example, with the economical use of a curb in the country, both vibropressed and vibrocasting or plastic curbs are suitable.

Much depends on the project and the area of application, the requirements for the curbstone in terms of strength, shape, etc. There is no one-size-fits-all answer. But the fact is unconditional that you need to pay attention not only to the choice of the product, but also to competent installation in order to achieve the desired result.

Installation features

Anyone can learn how to install both paving slabs and a curb block, paying attention to the laying technology. It is possible to install the curbstone correctly, provided the following step-by-step instructions are followed.

- Initial preparation of the trench based on the overall dimensions of the curb blocks used. For the curb, the depth will correspond to the height of the block, for the curb - only a third of it.

- Performing tamping of the trench area.

- Marking the proposed installation area using stakes and thread. The latter must be properly tensioned (without sagging), horizontally, using a level.

- Strengthening the curb by using dry sand-concrete backfill of the trench bottom for the purpose of solid block installation.

- Final adjustment / check of the fixed thread height depending on the assumed upper border of the curb.

- Preparation of cement slurry

- Direct laying of the curb stone according to the specified level (the block must be placed in the designated place and, using a mallet, make the necessary alignment).

- Putty joints. You need to lay the curb before starting to work with the tiles.

A visual overview of the installation of a sidewalk curb on your site is presented in the following video.

The comment was sent successfully.