Description of curb stones and their installation

Curb stones are used to build curbs - fences that are necessary to separate sidewalks and the roadway. Today in our article we will talk in more detail about what curb stones are, as well as how they are installed.

What it is?

Curb stones can be made from various materials (for example, concrete or granite). but their direct production is carried out on the basis of one of 2 existing methods: semi-dry pressing or vibration molding. Building blocks can be produced fully painted or unpainted.

The distinctive characteristics of curb blocks include the following:

- resistance to unstable temperatures;

- moisture resistance;

- strength and reliability;

- long service life;

- non-slip surface;

- a wide range of colors and sizes of stones;

- high level of heat transfer, etc.

Curb blocks are widely used in the arrangement of public areas and private areas.

Species overview

Today, there are several types of stones that are used for the construction of borders. Each of these types has its own individual characteristics and properties.

Road

This variety is considered the most popular, widespread and in demand. It is with the help of such curb stones that roadbeds are equipped.

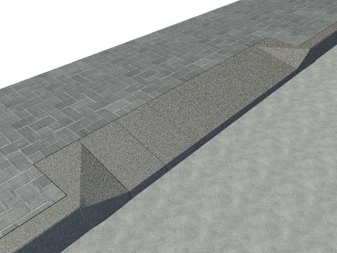

Garden

With the help of garden sidewalk curbs, you can equip various territories. So, these building elements are often used for sidewalks, swimming pools, flower beds, beds, etc.

Trunk

By the name of this type of curb stones, you can guess that they are very often used in the process of laying highways.

Entry

The most important distinguishing characteristic of entrance curb stones is the fact that they have a beveled outer part. They are usually placed where vehicles enter the sidewalk.

Thus, the specific type of curbstone should be chosen taking into account the purposes for which you will use it in the future.

Materials (edit)

When choosing a curb stone, your attention must be paid to what material this building element is made of. The raw material largely determines the qualities and characteristics of the curbstone. Depending on the material of manufacture, there are several types of building blocks.

Vibropressed

First of all, it is important to note the fact that vibropressed ones are characterized by a high level of strength. Besides, their distinctive characteristics include a long service life, as well as resistance to sudden changes in temperature and high humidity. Accordingly, you can install such building blocks in regions with any climatic conditions.

Concrete and reinforced concrete

These materials are the most popular and widely used in the manufacture of curb blocks. For example, for the manufacture of reinforced concrete stones, fine-grained reinforced concrete is used. This material has a high level of resistance to mechanical stress.

Granite

Experts report that granite curb blocks have the highest strength. At the same time, they are quite expensive, therefore, not everyone is available for purchase. It is also important to note the durability of such building blocks.

Marking

When buying curbstones, it is important to pay attention to their brand. Building block marking consists of letters and numbers and is divided into 4 parts:

- letter designation that indicates the type of product along the profile (cross-sectional shape);

- a number that indicates the length of the block in centimeters;

- a figure that indicates the height of the block in centimeters;

- a number that indicates the width of the block in centimeters.

In this case, for the convenience of the perception of information by the user, all numbers are separated by a dot.

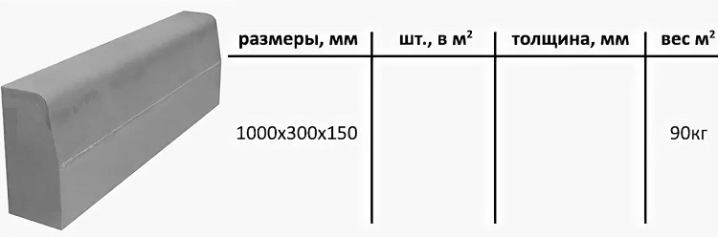

Dimensions and weight

On the territory of the Russian Federation, GOST is in force, which regulates such indicators and dimensions of curb stones as height, width, length and weight. So, for example, on the construction market you can find building blocks of the following dimensions: 1000x300x150, 1000x200x40, 500x200x80, 1000x200x80, etc. Moreover, each of the sizes weighs differently. By size and weight, there are several categories of curb stones:

- BR (private);

- BU (private widened);

- BUP (private broadened intermittent);

- BL (straight with tray);

- BV (entry);

- BK (radial, radius of curvature 5-15 m).

Consider the most popular curb block sizes:

- 1000x200x80 with a weight of 40 kilograms (most often used for arranging lawns and gardens);

- 500x200x30 with a weight of 6.65 kilograms (a fairly thin building block);

- 500x200x70 with a weight of 15 kilograms (the main manufacturing method is vibration casting);

- 500x200x80 with a weight of 18 kilograms (with the help of this variety, pedestrian zones are equipped);

- 500x200x60 with a weight of 16 kilograms (used in parks).

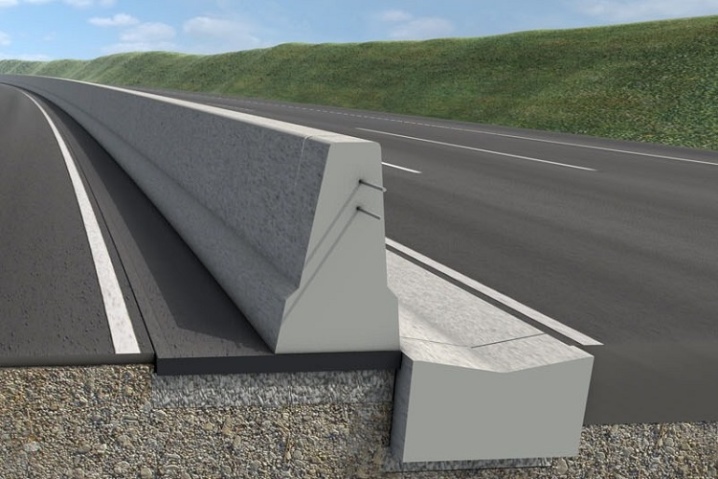

Installation features

Once you have selected and purchased a curbstone suitable for your purpose, it is important to install it correctly. Installation and installation can be done both with your own hands and with the help of qualified specialists. One way or another, the curbstone should be placed and laid strictly in compliance with all technologies and standards, the work must be carried out according to the current SNIP.

Wherein in advance, you need to prepare the corresponding scheme and the necessary tools (for example, forceps, tilting device, etc.). It is also important to remember about the mortar for masonry and grouting (for example, with cement-concrete coatings), on the basis of which the building curb blocks will be installed.

The procedure for installing curb stones is as follows.

- First you need to make preparatory work. First of all, this concerns the marking of the territory in which you will install building blocks. Traditionally, markings are made using specially designed elements, namely stakes and ropes. So, the rope is pulled over the stakes - in this way the line of the future curb is formed.

- The next step is to excavate a trench. For the main dimensions, you need to take the width of the curb, and then add 5 centimeters on each side. The depth of the trench should be 2/3 the height of the curbstone you are using.

- After that, the bottom of the trench you dug must be covered with rubble - the thickness of this layer should be 4 cm. On top of the crushed stone, you need to pour 2 centimeters of sand, and then this mixture is poured with water. The curb can then be placed in the trench.

- The final stage is the preparation of the fixing solution. To do this, you need to take cement, sand and water in a ratio of 1 to 3 to 1.5. This solution must be laid in an even layer, the thickness of which should be 2 centimeters.

Today, it is not necessary to install curb stones with your own hands. For these purposes, specialized devices have been developed and created - border stackers. It should be borne in mind that even if you installed the curb without errors, the life of the building blocks is limited.Accordingly, over time, you will have to carry out construction work to replace worn out elements.

If possible, experts recommend changing the entire curb at once, and not its individual stones.

Painting Tips

After installation, the border is usually painted. This process should be approached carefully, responsibly and accurately, since the final appearance of the fence will depend on your actions. First of all, it is worth preparing the materials and tools necessary for the work, in particular - paint, putty, primer, colors, etc. In this case, you need to carefully calculate the consumption of materials in advance. So, for example, when choosing a paint, one should take into account the fact that it will be applied to the border in several layers.

The choice of paint should be taken very seriously. First, it must be purchased from specialized hardware stores. At the same time, preference should be given to such a paint that is specially designed for outdoor use. This is due to the fact that it has such important characteristics as elasticity and strength. Accordingly, it will retain its original color for a long time and will not fade under the influence of sunlight, ultraviolet radiation, precipitation, etc.

Besides, the paint should be selected taking into account the material from which the curbs themselves are made - these materials should be well combined with each other. Another important factor to pay attention to is the composition of the paint. To familiarize yourself with it, you can read the label or ask the help of a sales assistant in a specialized store where you purchase building material. So, the composition of the paint must necessarily include chemical components that prevent the development of mold and mildew.

In addition to the choice of materials, it is also important to properly prepare the base of the curb stones. So, first of all, building elements need to be cleaned of dust, dirt, old paint, etc. If there are any defects on the surface, then you need to get rid of them - for example, cracks must be putty. After the preparatory steps are completed, you need to cover the curb with a soil layer.

Just like paint, the primer must be selected on the basis that it should be intended exclusively for outdoor use. It is recommended to apply this material with a roller. Also, it is imperative that you wait a day so that the primer dries well beforehand. Only after that, you can proceed to the direct painting of the structure.

As for the choice of the direct paint color, in this case it is recommended to focus solely on your preferences. So, you can paint the border with one or several colors at once. In any case, it should be remembered that the paint must be applied in several layers. The next layer should be applied only when the previous one is completely dry. The painting procedure itself must be carried out carefully, applying paint in a thin layer in order to avoid unwanted smudges and other defects. Paint with a roller to avoid brush streaks.

In addition, for convenience, you can use specially designed cartridges or sprayers.

In the next video, you will be laying the curbstone.

The comment was sent successfully.