Granite curbs and curbs

Curbs are an indispensable element of any road construction, it is installed to separate the boundaries of roads for different purposes. Thanks to the borders, the canvas does not crumble and serves faithfully for several decades. Granite products meet all quality requirements, in addition, they look stylish, therefore they are widely used in landscape design.

Peculiarities

Granite is one of the most durable finishing materials; therefore, stone is widely used in the improvement of the roadbed and the design of garden paths. Borders and curbs are made of granite... These elements separate the pedestrian zone from the carriageway, they are used to mark the boundaries of special zones. - for example, a cycle path.

And the curbs and curbs are made from side stone, the difference between them lies in the installation method. If it is flush with the ground, it is border... If some part of the height protrudes above the canvas and forms an obstacle, this is curb.

Basically, the difference between the blocks is just how deep you dig the tiles into the ground.

The popularity of granite is due to its undoubted advantages.

- Durability. The product can withstand intense mechanical stress without losing its aesthetic appearance and performance.

- Wear resistance. The material is resistant to abrasion.

- Frost resistance. Natural granite is not afraid of low and high temperatures, as well as temperature jumps.

- Density. The stone has small pores, so when moisture hits the surface, the material does not change its state.

- Undemanding care. If a part of the curb is damaged, you can always replace the failed part, without the need to dismantle the entire structure.

- Variety of tint palette. Depending on the deposit, granite can have a wide variety of colors, so everyone can choose the option that best fits into the landscape design.

- Availability. Granite products are widespread in all points of sale. In our country, there are dozens of large and small firms offering products of various shapes, colors and sizes.

- Environmental Safety. Granite does not emit toxic substances and radiation, therefore, it does not pose a threat to life and health.

The only drawback is the cost of the material... It largely depends on the pattern, texture and shade, as well as the method of delivery to the buyer. However, this minus is completely leveled by the durability of the product, in terms of the service life, the product can be classified as economical. That is why natural stone is used for the reconstruction of old roads. Unlike concrete, it retains its appearance and shape throughout its entire service life.

Types and classification

The most common type of curbs is straightforward, it has a rectangular shape. Depending on standard sizes and functionality, it is divided into several categories:

- GP1 - used to separate the carriageway and intra-quarter driveways from sidewalk areas and lawns, dimensions - 300x150mm, linear weight. m - 124 kg;

- GP 2 - to delimit roads from pedestrian zones in tunnels, on distribution lanes and at exit points, dimensions - 400 × 180 mm, weight running. m - 198 kg;

- GP 3 — for separating the carriageway of roads and pedestrian zones on road bridges, as well as in overpasses, dimensions - 600 × 200 mm, weight running.m - 330 kg;

- GP 4 - is used to separate pedestrian paths from flower beds, lawns and sidewalks, dimensions - 200 × 100 mm, linear mass. m - 55 kg;

- GP 5 - to separate footpaths from lawns and sidewalks. Size - 200 × 80 mm, weight m - 44 kg;

- GPV - for the arrangement of entrances from the carriageway to the pedestrian zone, dimensions - 200 × 150 mm, linear mass. m - 83 kg;

- in the private sector, GP5 curbs are usually used to improve the backyard territory - they are lightweight, convenient for laying and, moreover, have the most democratic cost.

Depending on the production option, the following types of borders are distinguished:

- sawn - has perfectly smooth edges, is used in squares and parks;

- chipped - obtained by crushing, has a natural look.

- polished - the method of polishing is used in the manufacture, thanks to which the stone acquires a flat and smooth surface;

- polished - has smooth edges with soft roughness;

- heat-treated - obtained after processing granite with a gas burner, this makes the surface slightly rough.

Manufacturers

The territories of the CIS countries are rich in deposits of the highest quality granite. Many stones are unique - in terms of color scheme and texture, they have no analogues in the world. The increased strength is explained by the fact that significant temperature fluctuations are typical for Russia, Belarus and Ukraine at different times of the year. - this process helps to strengthen and harden the rock. In terms of quality, Russian stone is in no way inferior to granite mined in Asia and South America, while significantly gaining in value. Even manufacturers from China, famous for their dumping policy, cannot make better price offers. You can not even mention European countries - their granite curbs are much more expensive.

All activities for the extraction and processing of granite are strictly regulated all over the world, which is why Russia adopted new GOSTs a few years ago, in which increased the requirements for the quality of the stone and reduced the permissible errors of finished borders.

Today, slab size deviations are 0.2%. This is slightly below the European level (0.1%), but at the same time above the Chinese level. This creates a significant competitive advantage for the products of the Russian manufacturer and makes the products of our enterprises in demand among the domestic consumer.

As for the manufacturers, it should be noted those that have earned the trust of consumers. The first lines of the ratings are occupied by Danila Master, Yurgan Stroy are also known among consumers of Stroykamen and Rosgranit. Do not give up positions Antik Trade, Albion Granit, Sovelit.

There are a lot of companies engaged in the production of granite. In your city, you can always find suppliers and buy good material, focusing on knowledge of its advantages and disadvantages.

Installation technology

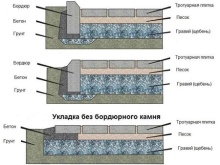

Laying a granite curb begins with preparation, namely - from digging a trench, its size should be slightly larger than the parameters of the tile itself.

The finished pit 20-25 cm is filled with sand and crushed stone, they act as a "pillow", and then tamped tightly to firmly fix the granite stone in the ground. After that, perform markup, for this, pegs are driven in at the beginning and end of the curb and a rope is pulled between them to control the position of the slab.

At the end of the preparatory work, you should prepare a cement mortar and treat the surface of the curb tile with it along the entire length of the side with which it will stand in the ground. The curb is placed in a trench, aligned strictly along the line of the rope and tapped with a special hammer until it is tamped into the "pillow". The entire border is installed according to this scheme. If you are forming a curb, then it should rise 7-10 cm above the ground level.

Advice: if the slab has significant weight and impressive dimensions, it is not necessary to cement it. It is enough just to place the curb in the trench, sprinkle it with soil and tamp it well.

If you decide to opt for this stone, it is very important to take his choice seriously. You should not only select quality material, but also make sure that it is made in accordance with international norms and standards.

The following video shows the installation of a border from Leznikovskoe granite GP-5 (size 200 * 80 * L).

The comment was sent successfully.