All about the road curb

The road curb is a key element in the construction of roads and highways. From the material in this article, you will learn what it is, what it is and what it is used for. In addition, we will tell you about its parameters and consider the key points of installation.

What is it and what is it for?

Road curbs - building material for road improvement. These are curb elements that are installed as fencing pedestrian zones from the roadway. They are installed on both sides of the road in order to effectively protect and strengthen the paved areas.

A road curb is needed to ensure the safety of drivers and pedestrians. It separates the roadway and the sidewalk. It strengthens and protects paving slabs from the negative effects of environmental factors (mechanical destruction, rain, snow, hail).

It is used to indicate transport stops, lawn. The road curb is used in the arrangement of arrivals and parking lots. It has a non-slip surface and a clear geometric shape. This allows it to be stacked to form perfect border lines.

The road stone can be seen on the safety islands. In addition to protection and zoning, it has a decorative function.

Road curbs are a building material with unique performance properties. They are resistant not only to external damage, but also to temperature extremes. Aesthetic, durable, wear-resistant, ergonomic. They make it possible to cover sidewalks with tiles (prevent their displacement), allow them to be asphalted.

They are a decorative design of paths in park areas. They are often used in the arrangement of private land holdings. They are located above the road surface (paving slabs or asphalt), do not dig too deep into the ground. They increase its frost and moisture resistance.

Peculiarities

The road curb is produced by the method of vibrocompression of extra strong heavy concrete. The raw material is a wet mixture of cement and coarse sand. The solution is kneaded in a concrete mixer, placed in a mold, pressed with simultaneous vibration. After that, they are dried at a temperature of 40-50 degrees, then packed on pallets.

The curbstone obtained by casting belongs to the budget type of material. Manufacturing technology with reinforcement for strength increases the weight of the product.

However, with the vibropressing technique, the possibility of curb splitting due to air bubbles is reduced.

Due to the continuous staining, it is characterized by color consistency. Building materials are manufactured in strict accordance with the current quality standards using modern equipment. It is environmentally friendly, has an affordable price, minimum production times for large batches.

It is installed in areas of different types, laying below the level of the underlying layer (made of reinforced concrete, sand and crushed stone). Due to its heavy weight, when installing it, special equipment will be used (or manual devices similar to pliers). The road curb is marked (for example, BR 100.30.15 - universal, reinforced and colored).

The road curb is not a curb, it differs in installation height. Goes in the same plane and height as paving stones. In this case, the roadway itself is located below the height of the stone. This prevents vehicles from entering the fenced-in pedestrian zone. In addition, it is thicker than the curb.

Species overview

All types of road curbs can be divided into 3 types. Each of them has its own characteristics and is different in purpose.

- Trunk gray, has a bevel on one side, which is located on the roadway. It has large dimensions in comparison with other analogs. Due to the inclination of the profile, it provides comfortable cleaning.

- Radial gray border, used in the centers of round intersections, intended for the enclosure of rounded sections. It has a standard height, can be installed on bends with a radius of up to 10 m. It is used for curved roads with difficult terrain and sharp bends.

- Made, characterized by a porous surface type, with a bevel on top. It is a chain of curb blocks of the same size and shape. Differs in the presence of a waterline (marks for the maximum permissible level of waste water).

- Beveled, differs from the others in that it does not create obstacles for cars, has a larger bevel on the side. Differs in long service life, resistance to pressure of transport rubber.

The geometry of the curbstone determines its price and weight. As for the weight, it can be different for products of the standard and reinforced type. In the first case, the mass is 95 kg, in the second - 100 kg.

With the same grade of concrete M300, the price for a regular border will be about 200-300 rubles per 1 piece. The cost of a reinforced stone will vary between 400-450 rubles per piece. The price of the painted analogue will be about 320 rubles per 1 module.

All types of road curbs are universal solutions for arrangement on Russian roads. According to the requirements of GOST 665-91, they differ in concrete strength not lower than M300, moisture absorption up to 5%, frost resistance from F200.

Often, the material provides for reinforcement with metal rods or wire. Its composition may include granite chips. Gray is considered universal. Colored is obtained by adding pigment. Such products are more expensive.

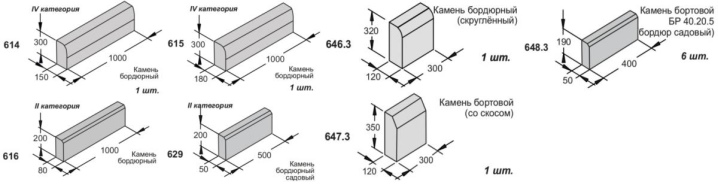

Standard dimensions and weights

Requirements for the road curb are spelled out in GOST 6665-91... It is used for furnishing 90% of all city roads and courtyards. Its service life is 15-20 years, depending on the location. The dimensions of the road curb depend on its varieties.

- Main curb is 180 mm wide, 1000 mm long, 300 mm high (highest), weighs 120 kg. Its width, height and length are constant.

- Standard road a curb with a length of 1 m has dimensions of height and width - 300x180 mm, weight 100 kg.

- Red meter the border is 1000x300x150 mm in length / height / width.

- Radial road the curb can have a length of 78 to 100 cm.Its width is 15 cm, its height ranges from 30 to 32 cm.The weight of a road curb directly indicates its quality: if it is less than the established standard in accordance with GOST, this means that it was produced in violation of technology ...

Installation nuances

To properly install a road curb, you need to know the nuances of the used laying technology. The work involves the use of equipment capable of lifting and moving stones weighing 100 kg. In the absence of technology, iron hooks are used.

The work is not done alone - at least two people do it.

First of all, it is necessary to take care of the preparation of the trench pit for the entire length of the curb material to be laid. When preparing the base, determine the location of the curb, using a rope for greater accuracy.

After that, a trench is dug out. Its width, according to the generally accepted installation technology, should be 40 cm (2 times more than a sidewalk, much more than a plastic analog). The depth of the trench should be greater than the height of the curbstone. The bottom of the dug trench is tamped, sand and crushed stone are laid out in layers. The embankment is leveled, re-compacted, and then poured with concrete mortar.

Then determined with the height of the curb.To do this, use a building level and a rope, fixing it on stakes, at an identical distance from the asphalt. The height of the curb will indicate where the outside of the curb will pass. At the end of this stage, they are engaged in installing the curb.

The stones are placed along the marking line together, lifting and moving simultaneously from both sides. The curb is deepened into the concrete solution, using a rubber hammer if necessary. The tool helps to adjust the height. They level the border on 2 planes. You can use a wooden plank and an iron hammer instead.

If, during installation, gaps are obtained between the stones, as well as other voids, they are poured with a prepared solution. From time to time, it is necessary to ensure that the curbs, before the solution hardens, do not fall in different directions. While they are not yet sealed, it is necessary to correct their position.

After the completion of the installation, they are engaged in the arrangement of sidewalks or roads. In order for the fence to stand for a long time, not to deform or break, the stone itself is examined before the start of work. You cannot mount it if large cracks and air cavities are visible on its surface.

The preparation of the foundation cannot be ignored. Sometimes pavers do not use crushed stone. However, if the soil is not sandy, you will not be able to do without it. It is absolutely necessary if the soil is clayey and has loam. In this case, ignoring the preparation technology will lead to the fact that in the spring the curbs will climb in different directions.

You cannot use construction waste or broken bricks instead of rubble. When using this "material", the curbs sink very quickly. As for the clay and black earth soil, it drowns gravel. In this case, you cannot do without laying geotextiles.

The comment was sent successfully.