All about bolt marking

Modern products for almost any purpose - from household to industrial - are made using fasteners: bolts, nuts, screws, screws. The fastener has its own markings, thanks to which you can determine its characteristics. To understand all the intricacies of hardware, you need to understand how they are marked and what this marking means.

Features of marking

The characteristics of the bolts are varied: you can find models with different threads, a certain type of head structure. The dimensions of the rod also differ. All information about the hardware necessary for the user has a designation located on its head. Before choosing hardware, it is necessary to determine their strength, which will be required to perform a high-quality fastener connection. Strength depends on the grade of steel from which the hardware is made. For example, strength requirements for furniture bolts will be lower than for anchoring joints that can withstand a load of more than 100 kg.

In some cases, the chemical composition of the bolt and its stability under the influence of various substances are subject to clarification.

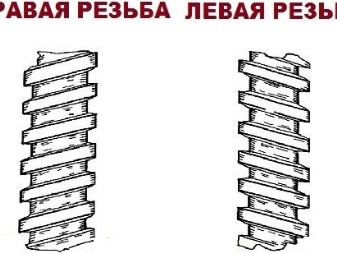

Certain tasks may be accompanied by specific requirements for the type of thread. For example, bolts used in difficult areas in an industrial environment will require a special type of thread on the metal rod body. The thread can be located in the course of cutting to the right or to the left - this feature of the hardware is also reflected in its standard marking. It is necessary to find out all the properties and characteristics of the bolt before starting the installation work, and it is the standard generally accepted marking that helps in this matter.

How is it labeled according to GOST?

Bolt markings in our country are regulated by strict GOST standards. GOST was adopted in 1977, and for foundation hardware - in 1980. In 2006, a new GOST appeared, but since the old issues of hardware, as practice shows, are still in use among consumers, you need to be able to read the marking of both standards.

The standard marking on each hardware has alphabetic and numeric designations.

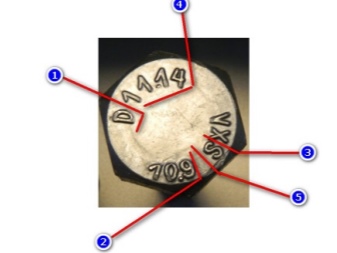

As a rule, on the head of a domestically-made bolt, there are letter designations on top, and digital symbols are located under them.

Marking in accordance with GOST 22353-77 of 1977 has its own reading rules.

- On the top row of designations, there is a stamp belonging to the manufacturer. Each plant has its own brand. Thus, on the heads of Soviet-made bolts, you can see the Latin letters WT, OC, L, D or Russian, for example, Ч and others.

- In the digital designation, the first number will indicate the ultimate strength of the bolt.

- After the numbers, you can see (but not on all products) a marking of the letters ХЛ. This is how they mark hardware that can be used in a cold climate at low temperature conditions, for example, in the Far North. The steel of such products can withstand temperature extremes and does not become brittle, retaining all its strength properties.

- Then the batch of the melt will be indicated in the marking. This designation informs about when and in what batch the product was made in production. In the case where the bolt has a non-standard left-hand thread, there will be a small arrow next to the manufacturing batch showing the counterclockwise direction. If there is no such arrow, then the bolt has normal right-hand threading.

GOST R52644-2006 of 2006 includes some changes.

- First comes the letter designations in the form of the manufacturer's hallmark. They have not changed and are performed in the same way as they did according to the old GOST.

- Further, the numbers indicate the parameters of the strength of the hardware product. These parameters must already meet the standards of the new GOST.

- After the designation of strength using letter symbols, indicate the scope of application of the product in relation to climatic conditions. Here, too, nothing has changed in the marking, and HL still means that the bolts can be used at low temperatures.

- Next, indicate the batch number of the melt.

- Then the strength of the hardware will be indicated. For example, the Latin letter S will mean that in front of you is the hardware that has the highest performance strength.

We have looked at the complete bolt markings, which contain quite a lot of information. But there is also a short marking that informs the user of the parameters of the hardware: section and length.

For example, you picked up a bolt with the designation 16X25, this will mean that in front of you is a hardware with a section of 16 mm and a length of 25 mm.

Decoding numbers

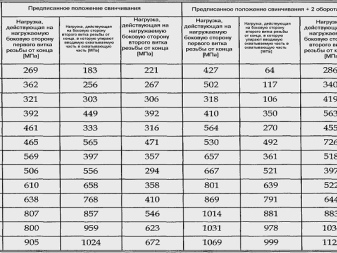

The most complete marking of the mounting bolts is given in the table. It has both an alphabetic and a numerical meaning, and all these symbols are located in a strictly defined order. If you indicate such a marking in the specification of a construction or installation project, any engineer can easily understand what kind of hardware is in question and what characteristics they have.

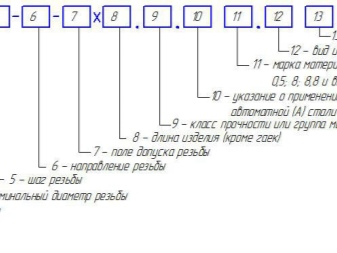

As an illustrative example, consider the designation of hardware, for which the marking is located on the head: Bolt A3M12x1.50LH-4gx60.66. S. 097.

- The first is the product name. The word "bolt" can be replaced by the name of another product, which is subject to marking.

- The letter A denotes the accuracy class of the product. In total, there are 3 classes of accuracy: A, B, C. A means that the accuracy of the bolt is high.

- Number 3 tells us about the type of product execution. According to the standards, there are 4 types of execution, but type 1 is not indicated in the marking.

- Next letter is M informs about the type of thread on the bolt shank. The type of thread is distinguished by conical, metric or trapezoidal. The letter M stands for metric.

- Number 12 indicates the diameter in millimeters at the bolt shank. It is noteworthy that only class A products have the M12 marking.

- Number 1.50 gives information about the pitch at which the bolt is threaded. If the thread pitch is standard for the diameter, it is not indicated in the marking.

- Letters LH show that the bolt has a left-hand thread. In the case where threading is done as standard right-handed, this is not displayed in the marking.

- Designation 4g informs about the accuracy class. The thread is cut with an accuracy on a scale from 4 to 8. The lower the indicator, the more precisely the thread on the hardware is made.

- Number 60 indicates the length of the bolt. In this example, it is 60 mm.

- Number 66 speaks of strength. These temporary hardness parameters are separated from the length by a dot.

- The next letter denotes the grade of the steel alloyfrom which the bolt is made. The letter C means that the hardware is made of so-called calm steel. If the letter A was in the marking, it would mean that the steel is automatic.

- Digits 097 show what kind of coating the hardware has. In total, 13 types of coating are distinguished, with the number 9 marking galvanized hardware. The number 7 denotes the thickness of the coating in microns, in our case the thickness of the galvanized coating is 7 microns.

Uniform requirements for hardware and their marking, adopted in our country, make it possible to accurately and quickly select fasteners. For products of European or American production, the marking is different, since the dimensions are indicated in inches. Conversion tables are used to read inch designations.

All about bolt marking in the video below.

The comment was sent successfully.