All about tie bolts

Knowing everything about tie bolts is very important in a wide variety of jobs. There are models for formwork and for door handles, bolts for M16 timber, window and other models. Before choosing and installing them, you will need to study the specialized GOST and other nuances.

Peculiarities

The construction of various buildings and structures is unthinkable without many connections. And in many cases it is possible to perform these very connections with the help of tie bolts. This type of fittings is becoming more popular from year to year. Unlike the same concrete screed, it can be easily dismantled, restored if necessary, or moved to a new location. In addition, the installation time is significantly longer than when using other options, and there is no particular difference in reliability.

This type of fastener is covered by GOST 7798-70. According to this standard, a grade B hex head must be used. The thread cross-section is 6 to 48 mm. Additionally, it is worth considering the use of GOST R 57899-2017. This standard sets out the general technical conditions for anchors and ties used in formwork.

A high-quality tie bolt connects the formwork quite effectively. Mechanical deformation of concrete mixtures is excluded. This property is typical even when installing heavy, powerful structures.

Important: small structural elements can be installed without the use of such bolts, exclusively on slopes and external supports. In addition to the main fasteners, you will have to use a couple of nuts and a couple of washers in addition to the nuts.

Applications

The tie bolts can be used not only for formwork, but also for door handles. A similar solution is used on hollow door leaves. There is no other way to attach the handles to them. It should be noted that in this case, the hole for the ties must match at the handle and the lock. However, a very wide socket at the handle or a non-standard lock can do a lot of harm, then you have to somehow be sophisticated.

For a bar, not only a simple clamping bolt can be used, but also its modification - a "force" spring block. Some people use such fasteners to successfully assemble even whole wooden houses. Their reliability is quite high. Such a connection provides not only the prevention of horizontal displacement of the beams, but also the pressing of different structural elements to each other. Even with a strong draft at home, everything is effectively compressed, and therefore there will be no deviations.

Window tie bolts are sometimes used. Their use on wooden windows, however, is hampered by the great rarity of such fasteners. It is readily used, but it is extremely difficult to find suitable products in the retail network. The most common name is OSM-6 window screed. More detailed information can always be obtained from consultants in the store.

What are they?

The size range of formwork fasteners is now quite wide. Their strength according to DIN 18216 can range from 85 to 240 kN. For the manufacture of such bolts, steel from St20 to St35 is used. The M16 size is relatively rare. Products with a diameter of 15, 20 or 25 mm are much more common.

Structures with a cross section of 15 mm have an actual cross section of 177 mm2. In this case, the specific gravity of 1 m of rolled products will be 1.38 kg. The maximum deviation for all indicators is taken equal to 4%. With a cross section of 20 mm, these parameters:

314 mm2;

2.44 kg;

4%.

With a section of 25 mm, they will be:

490 mm2;

3.8 kg;

4%.

Mounting

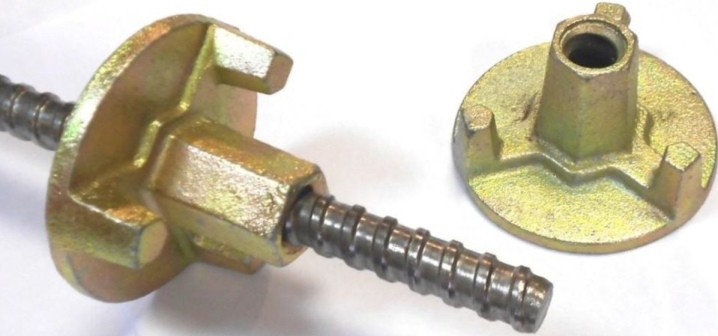

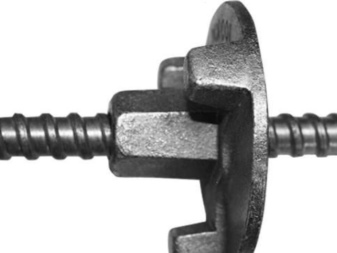

A pair of special nuts helps to secure the formwork clamping screw. They must be accurately cast from an extra strong or ductile iron grade. To avoid difficulties with screwing the nut onto the bolt, chamfer is removed for its entry. In this case, the contact area with the formwork shield increases. Usually it is 90 - 100 mm.

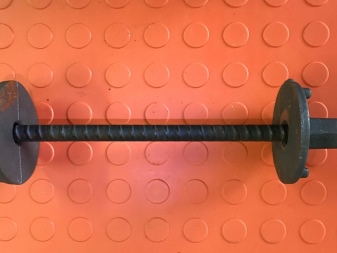

But in especially difficult situations, due to the addition of washers with a cross section of up to 180 mm, the size of the contact area is further increased. A polymer pipe will help prevent the destruction of the screws by the concrete mixture. Thanks to it, further dismantling of the formwork is greatly simplified. The outer section of the threaded tie should be 1.7 cm, and inside it is 1.5 cm. Thread smelting is usually done immediately, but it can be cut later.

Such fasteners are universal and compatible with formwork of any shape and size. Therefore, it can be used when working with a wide variety of types of monolithic wall blocks. Additionally, a plastic tube is used (which should be larger than the bolt in cross section). Cone clips are inserted from both sides of the pipe. When installing a clamping block without plastic protection, reuse is impossible; if such protection is used, the bolt can be easily removed.

Low alloy steel formwork bolts give the best results. They are made using hot rolled products. For your information: in professional sources, the same product can be referred to simply as a "tie", an anchor rod or even a "hairpin". Together with the tie bolt the following can be used:

lamb;

hex;

hinged type of nut.

Before installing the shields, it is necessary to drill channels of a suitable section inside them. If a typical clamping bolt is used, screeds with a diameter of 2.2 cm are used. It is necessary to punch the channels not at the edge itself, but at least 10 cm from the edge. A fixing cone, a plastic pipe and the next fixing cone are attached to the inserted bolt. The opposite edge of the hairpin comes out through a special hole in another shield; the edges of the bolt extend beyond the shields to the extent that the nuts are loosely fastened, and washers could be placed in front of them.

The nuts are tightened along the thread, changing the gaps between the shields. This gap must correspond to the design thickness of the structure under construction. When the mixture hardens, the screeds will need to be removed. Unscrew the nuts on both sides, then remove the washers. The pin must be removed from the tube, but the tube and the fixing element remain inside.

The following video talks about the tie bolt.

The comment was sent successfully.